Method for preparing fiber-reinforced epoxy resin-based composite material super-hydrophobic surface

A fiber-reinforced material and super-hydrophobic surface technology, which is applied in the field of super-hydrophobic surface material preparation, can solve the problems of unsuitable super-hydrophobic surface preparation, etc., and achieve good industrial application prospects, simple operation process, good self-cleaning and waterproof Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

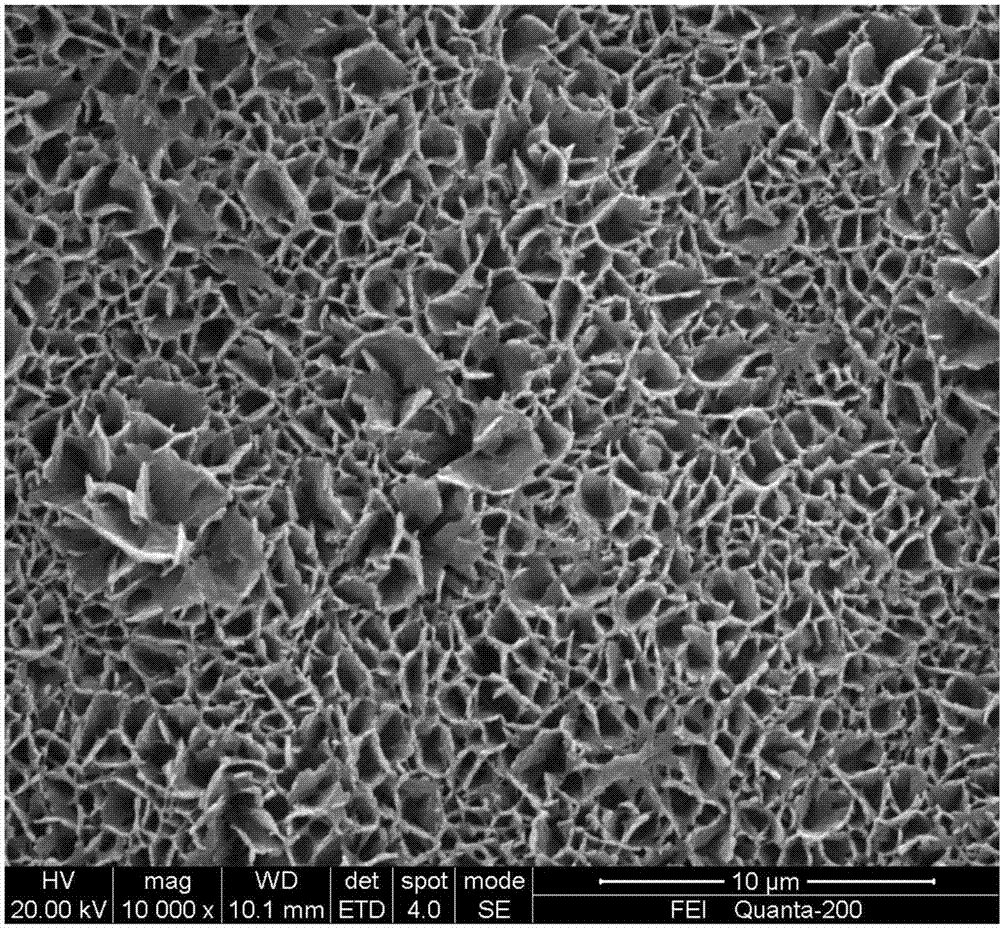

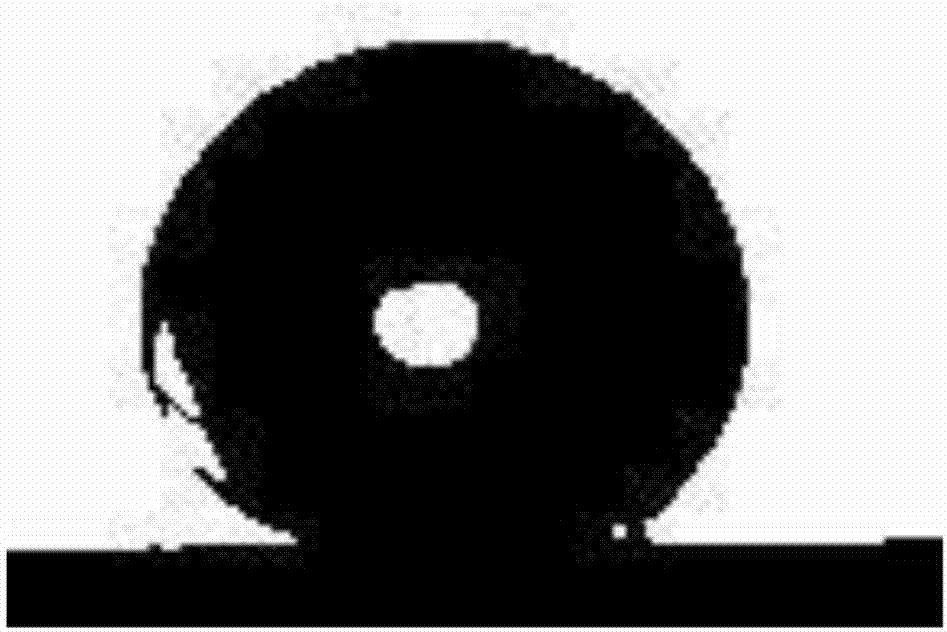

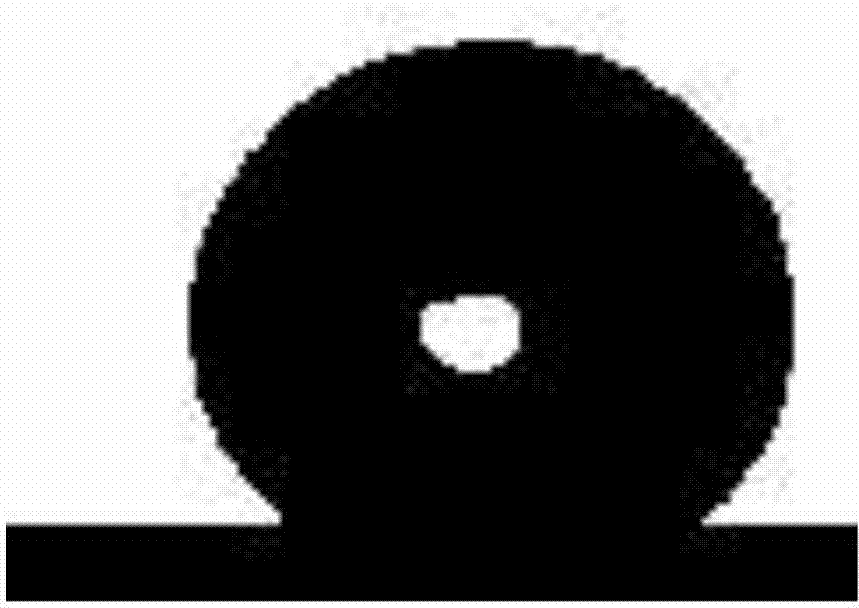

[0026] A kind of preparation method of superhydrophobic surface of fiber-reinforced epoxy resin matrix composite material of the present invention, comprises the following steps:

[0027] 1. Prepare ingredients

[0028] 1.1 Prepare fiber reinforced material: take carbon fiber cloth and cut it into 10cm×15cm, set aside;

[0029] 1.2 Prepare inorganic powder calcium carbonate (or zinc oxide);

[0030] 1.3 Prepare E-51 epoxy resin glue and diethylenetriamine for use.

[0031] 2. Prepare the resin system

[0032] 2.1 Mix and dilute 8g of calcium carbonate and 2g of E-51 epoxy resin glue in 50ml of acetone, stir well and then add 0.2g of diethylenetriamine to form the outer coating resin system;

[0033] 2.2 Weigh 8g of E-51 epoxy resin glue and 0.8g of diethylenetriamine and mix well to form the middle layer resin system.

[0034] 3. Coating resin system

[0035] Take a molding mold, polish the mold and apply a release agent, and place the release paper in the mold; then appl...

Embodiment 2

[0042] A kind of preparation method of superhydrophobic surface of fiber-reinforced epoxy resin matrix composite material of the present invention, comprises the following steps:

[0043] 1. Prepare ingredients

[0044] 1.1 Prepare fiber reinforced material: take carbon fiber cloth and cut it into 15cm×15cm for use;

[0045] 1.2 Prepare inorganic powder calcium carbonate (or zinc oxide);

[0046] 1.3 Prepare E-51 epoxy resin glue and diethylenetriamine for use.

[0047] 2. Prepare the resin system

[0048] 2.1 Mix and dilute 7g of calcium carbonate and 3g of E-51 epoxy resin glue in 50ml of acetone, stir well and then add 0.3g of diethylenetriamine to form the outer coating resin system;

[0049] 2.2 Weigh 27g of E-51 epoxy resin glue and 2.7g of diethylenetriamine and mix well to form the middle layer resin system.

[0050] 3. Coating resin system

[0051] Take a molding mold, polish the mold and apply a release agent, and place the release paper in the mold; then apply th...

Embodiment 3

[0058] A kind of preparation method of superhydrophobic surface of fiber-reinforced epoxy resin matrix composite material of the present invention, comprises the following steps:

[0059] 1. Prepare ingredients

[0060] 1.1 Prepare fiber reinforced material: take glass fiber cloth and cut it into 20cm×20cm for use;

[0061] 1.2 Prepare metal oxide powder zinc oxide (or calcium carbonate);

[0062] 1.3 Prepare E-51 epoxy resin glue and diethylenetriamine for use.

[0063] 2. Prepare the resin system

[0064] 2.1 Mix and dilute 9g of calcium carbonate and 1g of E-51 epoxy resin glue in 80ml of acetone, stir well and then add 0.1g of diethylenetriamine to form the outer coating resin system;

[0065] 2.2 Weigh 49g of E-51 epoxy resin glue and 4.9g of diethylenetriamine and mix well to form the middle layer resin system.

[0066] 3. Coating resin system

[0067] Take a molding mold, polish the mold and apply a release agent, and place the release paper in the mold; then apply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com