A process for recycling waste water from unsaturated polyester resin industry

A technology of polyester resin and industrial wastewater, applied in the direction of heating water/sewage treatment, etc., can solve the problems of non-universal technical methods, complex characteristics of wastewater quality, and high cost of wastewater treatment, and solve the key technical problems of engineering scale-up, The effect of improving the conversion rate of raw materials and improving the resource recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The high-concentration unsaturated polyester wastewater produced in the production process of an unsaturated resin enterprise, the composition and concentration are: phthalic anhydride, maleic anhydride, oxalic acid, diethylene glycol, propylene glycol, glycerin, n-butanol, and the COD is 80000mg / L , utilize the present invention to carry out processing step as follows:

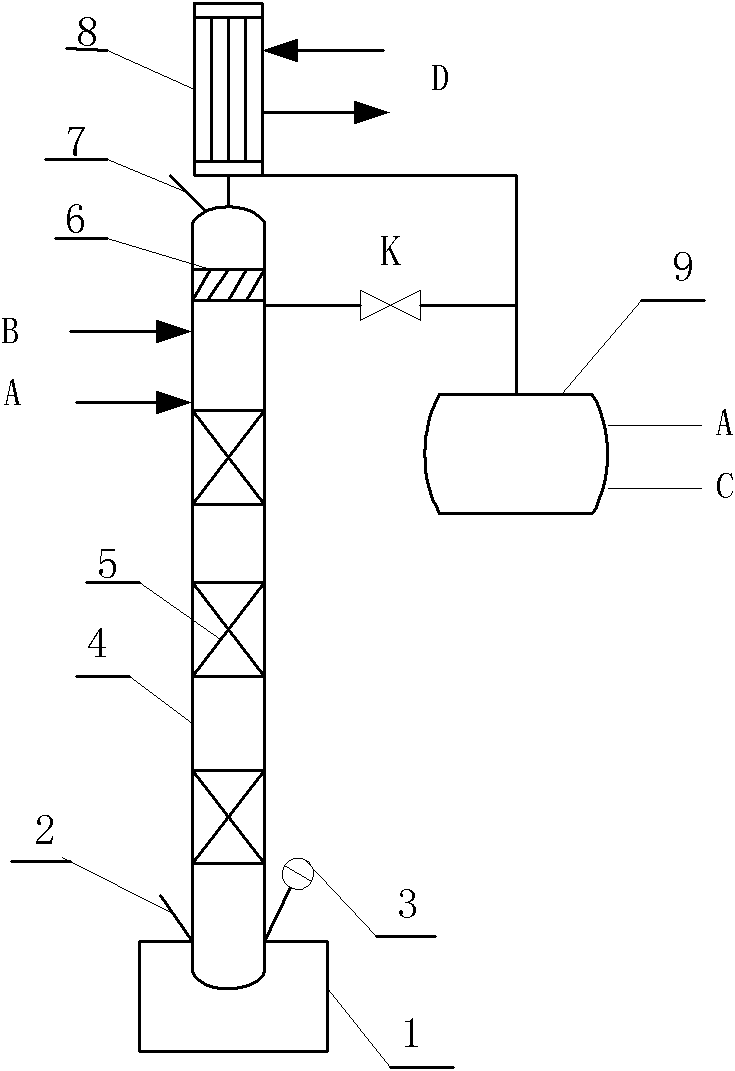

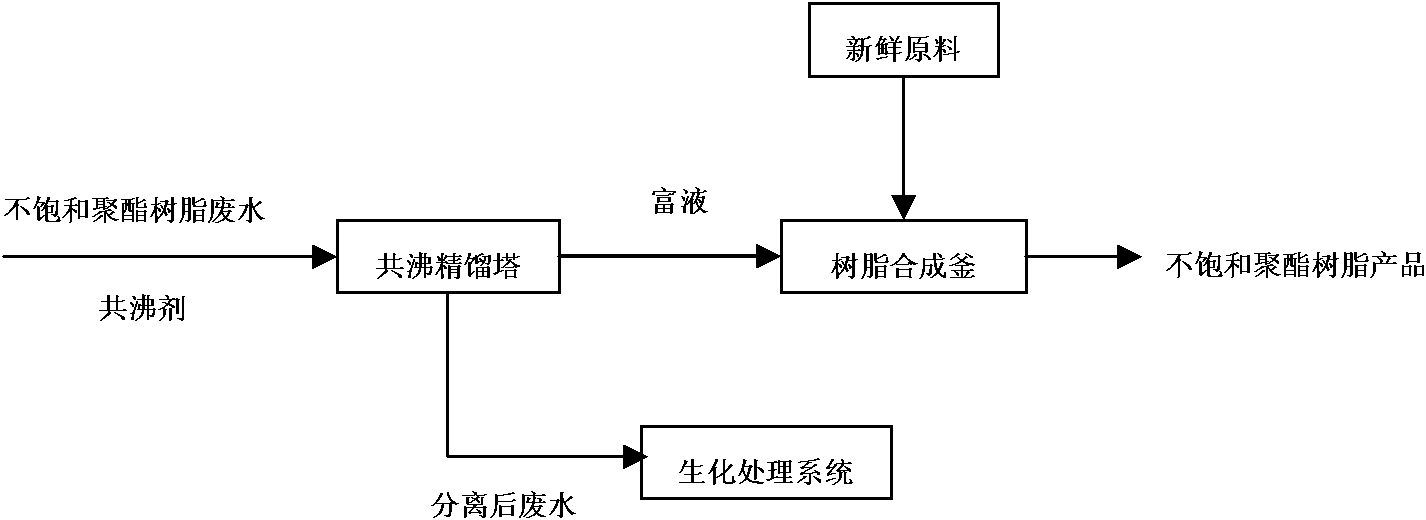

[0024] 1) Azeotropic distillation process: Cyclohexane is used as an entrainer, and the entrainer and unsaturated resin wastewater are added into the tower from the raw material inlet of the azeotropic rectification tower filled with wire mesh corrugated packing at a volume ratio of 0.5:1. ; At the top of the azeotropic distillation tower, after the steam of the material is condensed by the condenser of the azeotropic distillation tower, part of it flows back into the azeotropic rectification tower, and the other part is taken out and enters the separation tank to automatically stratify into water phase...

Embodiment 2

[0027] The composition and concentration of high-concentration unsaturated polyester wastewater produced during the production process of a resin enterprise are: ethylene glycol, propylene glycol, phthalic anhydride, and terephthalic acid. COD is 100000mg / L, utilizes the present invention to carry out processing step as follows:

[0028] 1) Azeotropic distillation process: n-propanol is used as an entrainer, and the entrainer and unsaturated resin wastewater are added to the tower from the raw material inlet of the azeotropic distillation column filled with Pall ring packing at a volume ratio of 0.7:1 ; At the top of the azeotropic distillation tower, after the steam of the material is condensed by the condenser of the azeotropic distillation tower, part of it flows back into the azeotropic rectification tower, and the other part is taken out and enters the separation tank to automatically stratify into water phase and oil phase. Phase, the reflux ratio is 1.5:1, the operating...

Embodiment 3

[0031] The composition and concentration of high-concentration unsaturated polyester wastewater produced during the production process of a resin factory are: diethylene glycol, maleic anhydride, and styrene. COD is 120000mg / L, utilizes the present invention to carry out processing step as follows:

[0032] 1) Azeotropic distillation process: carbon tetrachloride is used as an entrainer, and the entrainer and unsaturated resin wastewater are added to the tower from the raw material inlet of the azeotropic distillation tower filled with PVC inclined tube packing at a volume ratio of 0.9:1. Inside; at the top of the azeotropic distillation tower, after the steam of the material is condensed by the condenser of the azeotropic distillation tower, a part of it flows back into the azeotropic rectification tower, and the other part is taken out and enters the separation tank to automatically stratify into water phase and The oil phase, the reflux ratio is 2:1, the operating pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com