Anionic emulsified asphalt and preparation method thereof

A cement emulsified asphalt, anion technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of limited source of raw materials, narrow temperature adaptation range, complex production process, etc., to achieve excellent physical and mechanical properties, temperature adaptation range. Wide, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

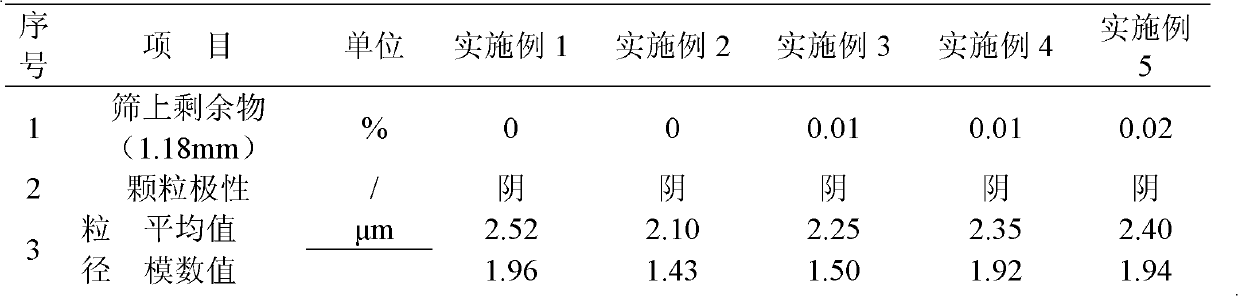

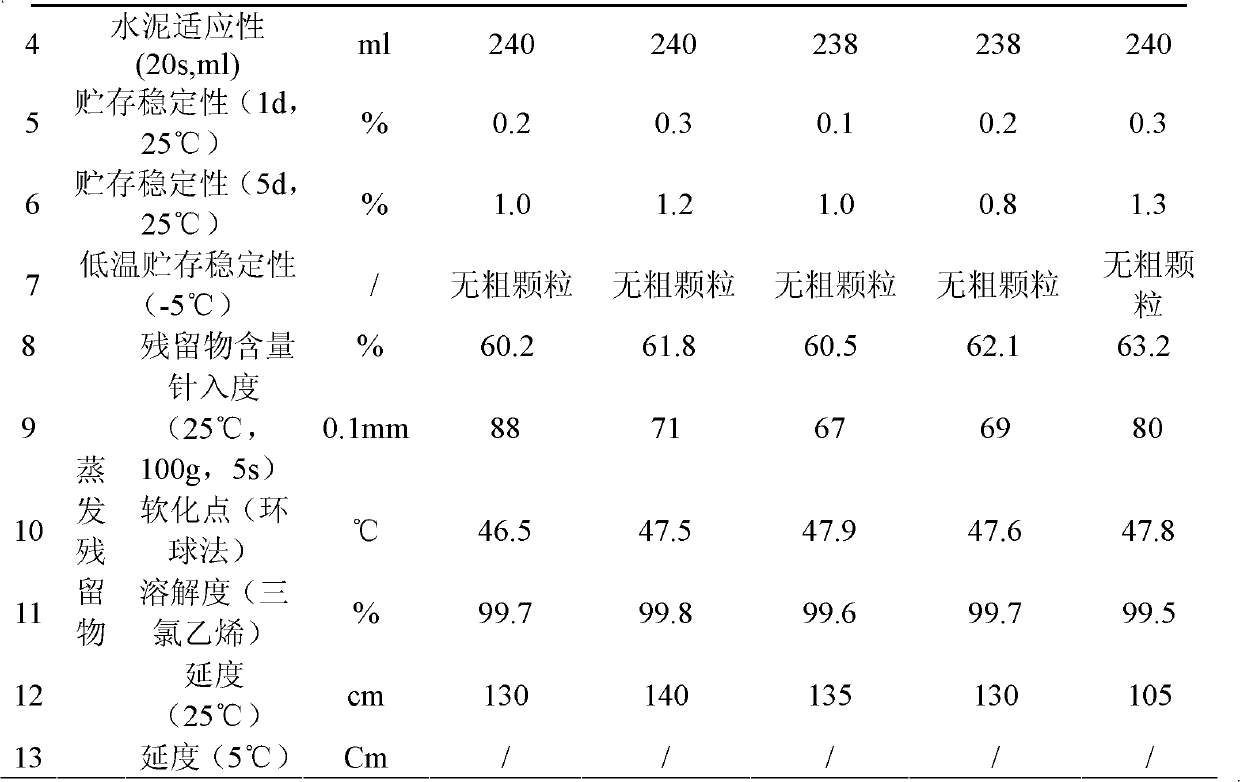

Examples

Embodiment 1

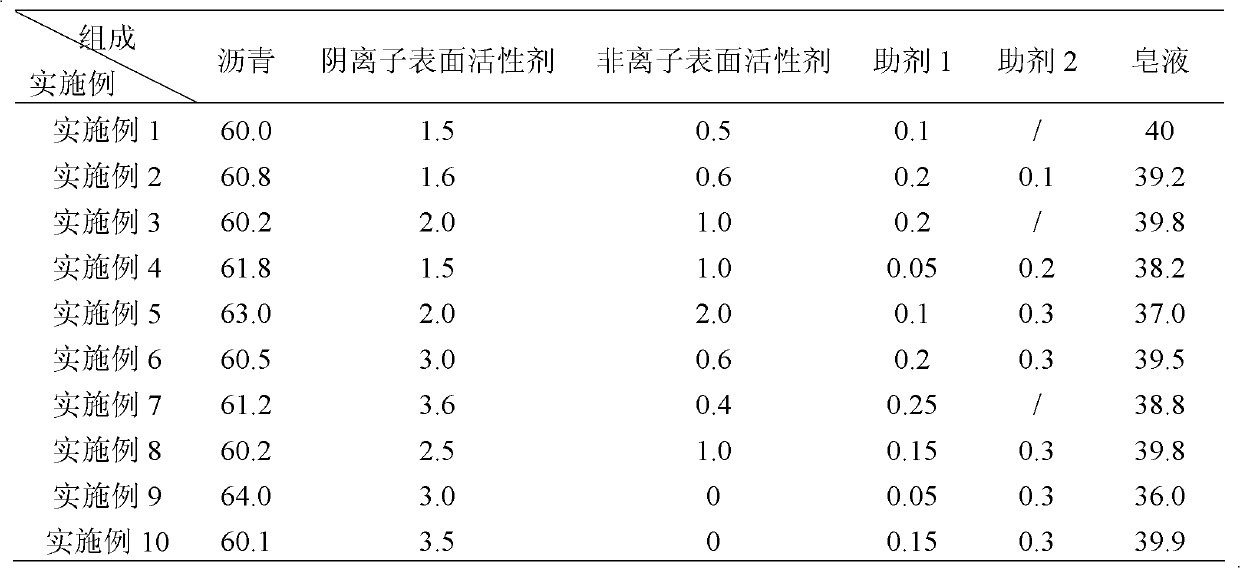

[0034] Embodiment 1, the preparation of emulsified asphalt

[0035] The raw materials used in the emulsified asphalt provided by this implementation are as follows: asphalt is CNOOC 36-1AH-90; anionic surfactant is hexadecyl sulfonate; Average molecular weight is 646); Additive 1 is sodium carboxymethylcellulose (number average molecular weight is 6400 ± 1000), and the weight percentage of above-mentioned components is as shown in table 1.

[0036] Concrete preparation method comprises the following steps:

[0037] (1) Heat the above-mentioned asphalt to 130°C, measure it for later use;

[0038] (2) Dissolve the above-mentioned sodium carboxymethylcellulose in cold water, dilute it in a ratio of 1:100, and set aside;

[0039] (3) Dissolve hexadecyl sulfonate, octylphenol polyoxyethylene ether and diluted sodium carboxymethyl cellulose in water at about 60°C according to the above weight ratio, prepare soap liquid, and use 2mol / l NaoH aqueous solution to adjust the pH value...

Embodiment 2

[0042] Embodiment 2, the preparation of emulsified asphalt

[0043] The raw materials adopted in the emulsified asphalt provided by this implementation are as follows: asphalt is CNOOC 36-1AH-90; anionic surfactant is lauryl sulfate; nonionic surfactant is polyoxyethylene lauryl ether (number average molecular 694); auxiliary agent 1 is calcium chloride, auxiliary agent 2 is polyacrylamide (number average molecular weight is 6 million to 20 million), and the weight percentages of the above components are shown in Table 1.

[0044] Concrete preparation method comprises the following steps:

[0045] (1) Heat the above-mentioned asphalt to 130°C, measure it for later use;

[0046] (2) Dissolve the above-mentioned polyacrylamide in cold water, dilute it in a ratio of 1:100, and set aside;

[0047] (3) Dissolve lauryl sulfate, polyoxyethylene lauryl ether, calcium chloride and diluted polyacrylamide in water at about 60°C according to the above weight ratio, prepare soap, and use...

Embodiment 3

[0050] Embodiment 3, the preparation of emulsified asphalt

[0051] The raw materials used in the emulsified asphalt provided by this implementation are as follows: asphalt is CNOOC 36-1AH-70; anionic surfactant is dodecylbenzenesulfonate; nonionic surfactant is nonylphenol polyoxyethylene ether ( The number average molecular weight is 660); the auxiliary agent 1 is polyvinyl alcohol (the number average molecular weight is 6 million to 20 million), and the weight percentages of the above components are shown in Table 1.

[0052] Concrete preparation method comprises the following steps:

[0053] (1) Heat the above-mentioned asphalt to 135°C, measure it for future use;

[0054] (2) Dissolve the above-mentioned polyvinyl alcohol in cold water, dilute it in a ratio of 1:10, and set aside;

[0055] (3) Dissolve dodecylbenzenesulfonate, nonylphenol polyoxyethylene ether and diluted polyvinyl alcohol in water at about 60°C according to the above weight ratio, prepare soap, and adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com