The preparation method of sic/stainless steel composite vascular stent material

A vascular stent and stainless steel technology, which is applied in the field of preparation of a SiC/stainless steel composite vascular stent material, can solve the problems of vessel wall damage, stenosis, technical complexity, etc., and achieve the effect of uniform internal tissue, good mechanical properties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

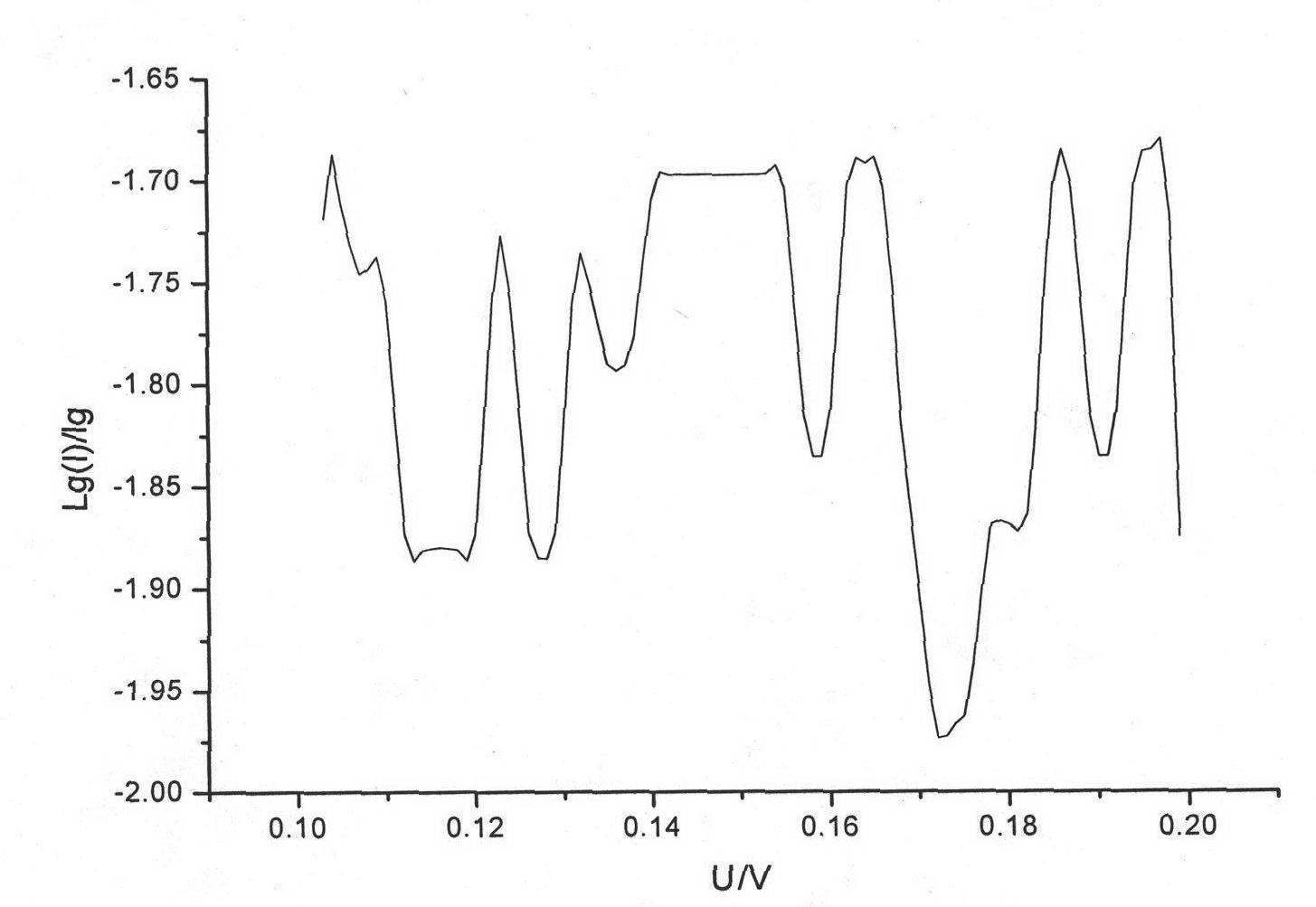

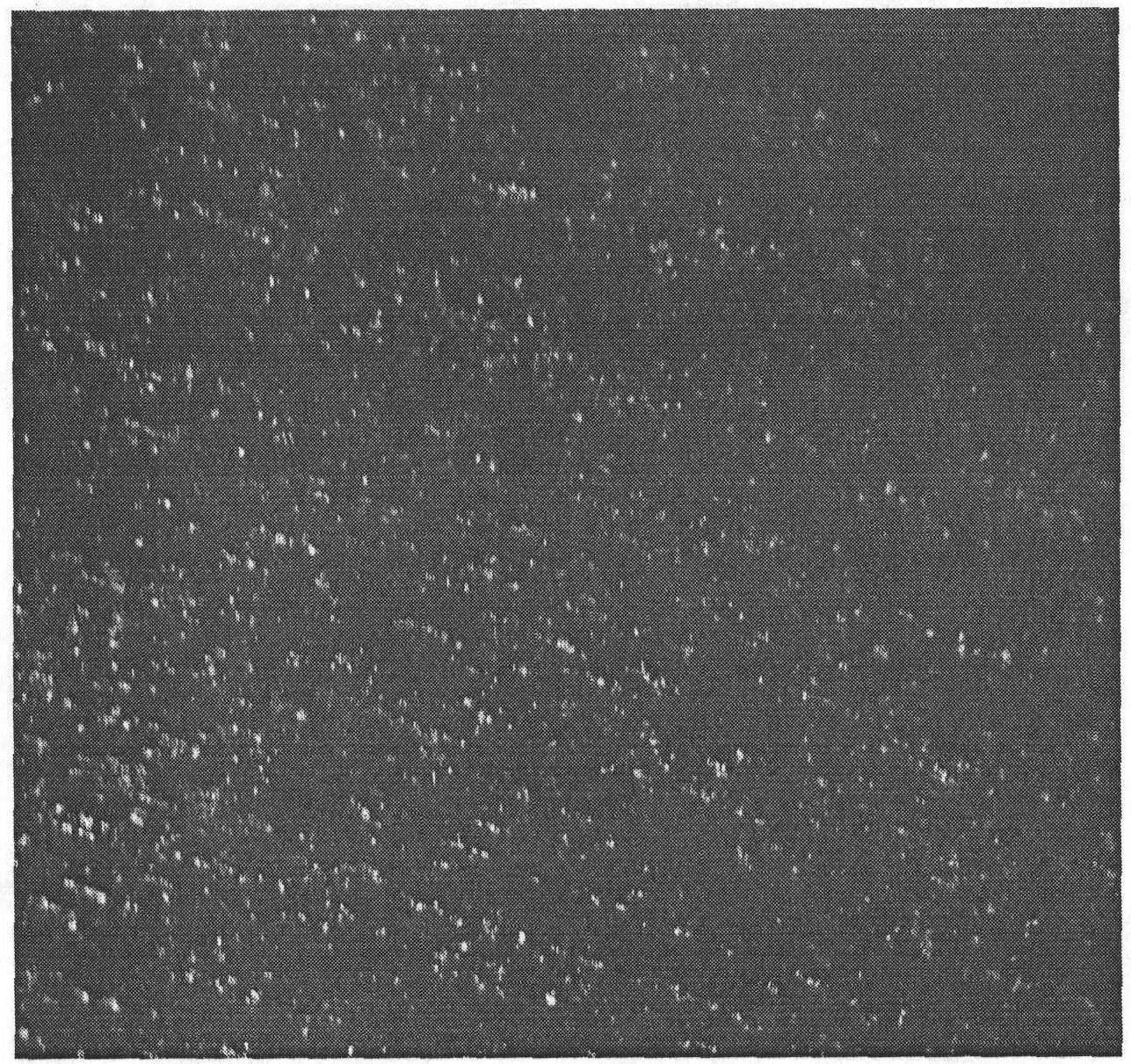

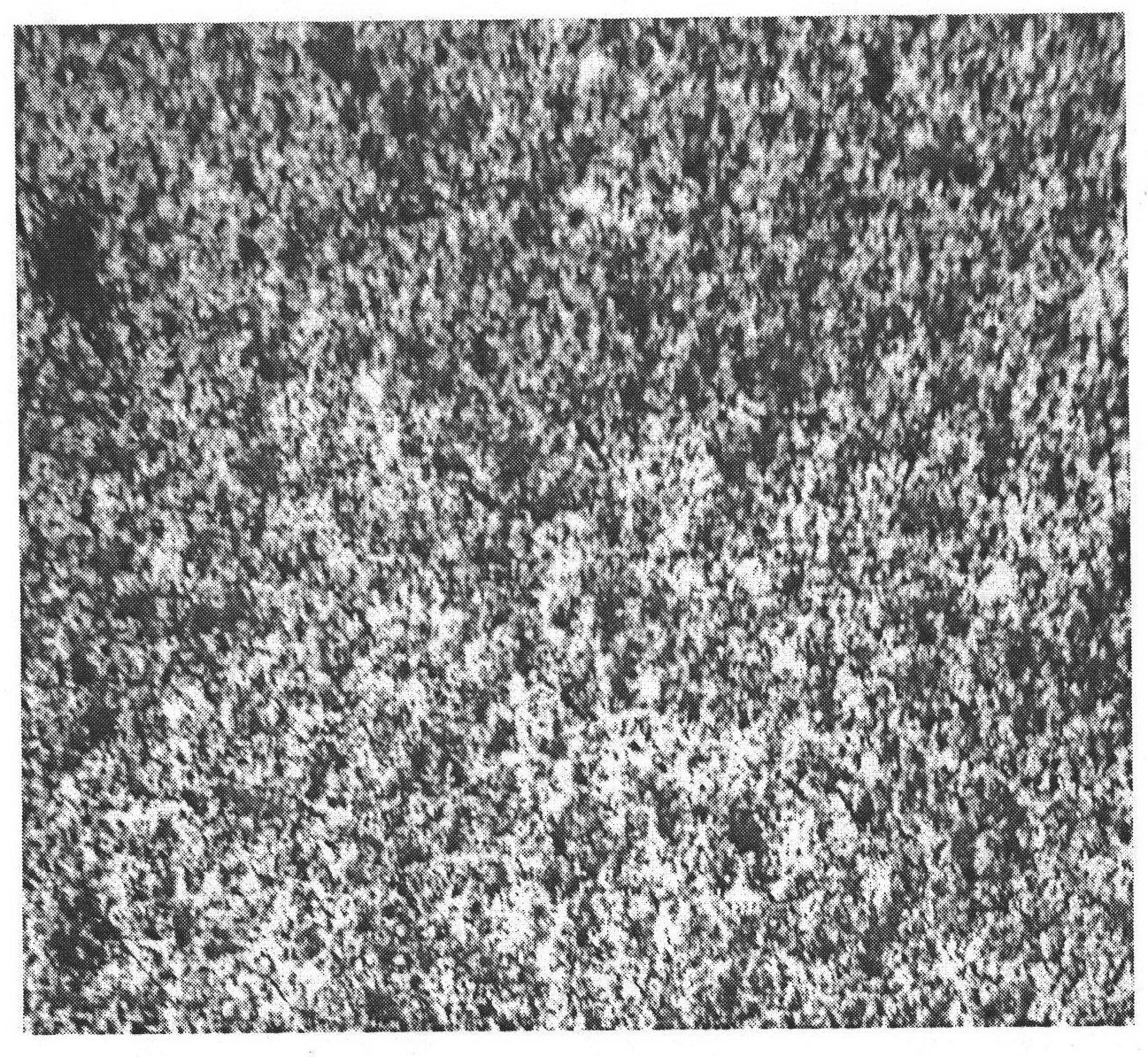

Image

Examples

Embodiment 1

[0023] Choose the best median diameter D 50 20μm 304L stainless steel powder, the best median diameter D 50 For SiC powder of 60 μm, the batching calculation is carried out according to the volume ratio of SiC:304L=75:25. According to the calculated value, use the electronic balance to weigh the required raw materials, and record the actual weighing results during the actual weighing. The recording results are shown in Table 1.

[0024] The quality of different raw materials in the batching of table 1 embodiment 1

[0025]

[0026] Put the weighed SiC powder and 304L stainless steel powder into the stainless steel ball mill tank, and then put them into 300 small stainless steel balls and 150 medium stainless steel balls of the QM-3SP4J planetary ball mill, and then Put in 150mL of distilled water. After everything has been filled, place the ball mill jar in the stand of the ball mill and secure it. After the ball mill tank is fixed, set the ball mill parameters as foll...

Embodiment 2

[0030] Choose the best median diameter D 50 304L stainless steel powder of 15μm, the best median diameter D 50 For SiC powder of 80 μm, the batching calculation is carried out according to the volume ratio of SiC:304L=50:50. According to the calculated value, use the electronic balance to weigh the required raw materials, and record the actual weighing results during the actual weighing. The recording results are shown in Table 2.

[0031] The quality of different raw materials in the batching of table 2 embodiment 2

[0032]

[0033]Put the weighed SiC powder and 316L stainless steel powder into the stainless steel ball mill tank, and then put them into 300 small stainless steel balls and 150 medium stainless steel balls of the QM-3SP4J planetary ball mill, and then Put in 200mL absolute ethanol. After everything has been filled, place the ball mill jar in the stand of the ball mill and secure it. After the ball mill tank is fixed, set the ball mill parameters as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com