Tubeless heat exchanger and waste heat recovery system

A waste heat recovery system and heat exchanger technology, which can be used in heat exchanger types, indirect heat exchangers, regenerative heat exchangers, etc. problems, to achieve the effect of reducing volume and steel consumption, reducing equipment cost and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

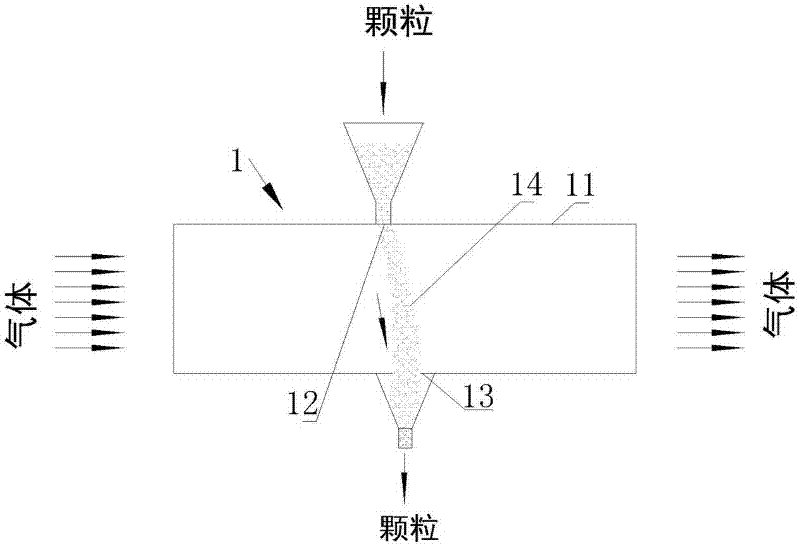

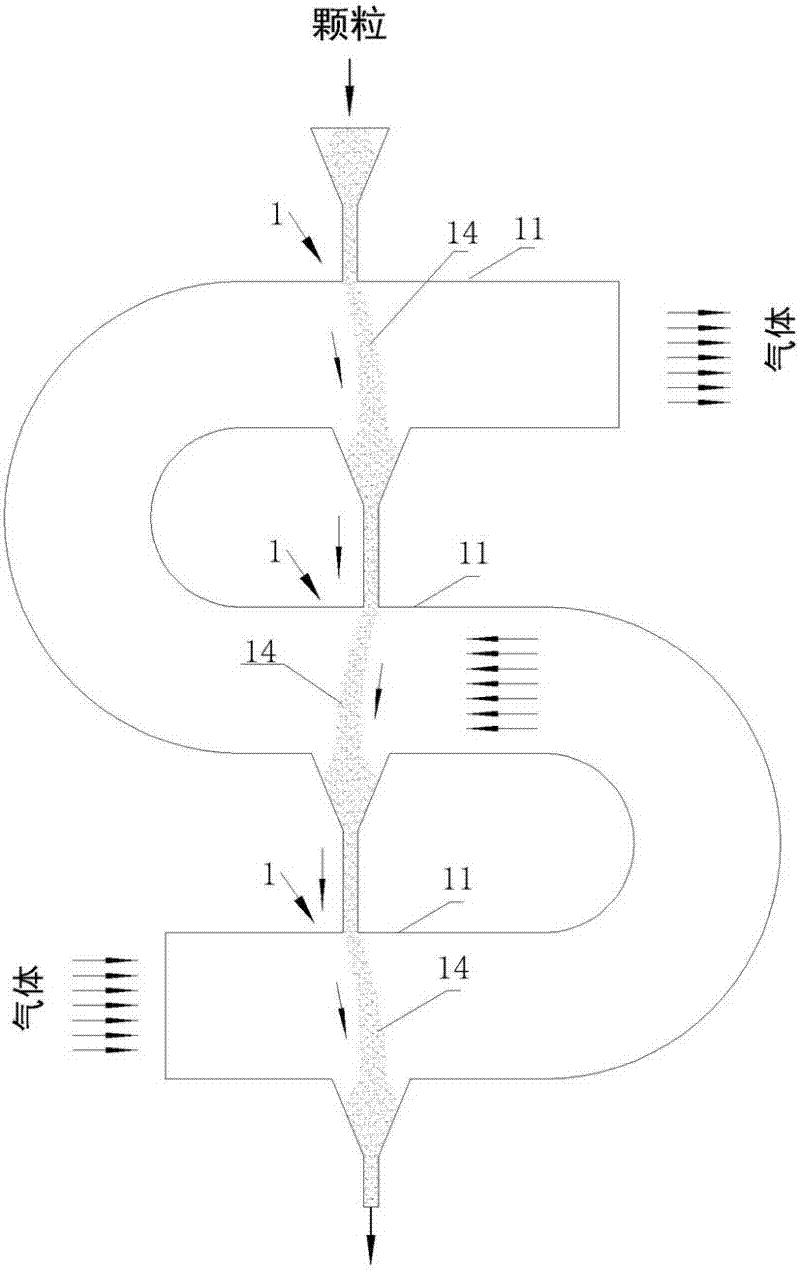

[0068] Embodiment 1: It is a serpentine elbow type three-stage waste heat recovery system, see Figure 7-Figure 12 .

[0069] It can be used when the boiler or other reactor tail gas discharge pipes and preheating air pipes have sufficient layout space in the height direction Figure 7 with Figure 12 One of the tubeless heat exchangers used in these systems are serpentine tubeless heat exchangers, of which Figure 7 It is shown that the air tubeless heat exchanger B is arranged vertically below the flue gas tubeless heat exchanger A and is vertically connected in series with the flue gas tubeless heat exchanger A. The high-temperature flue gas enters from the lower part of the flue gas tubeless heat exchanger A and is discharged from the top. The particles naturally fall from the top hopper by gravity to form a three-stage particle curtain, and exchange heat with the rising hot flue gas in turn during the falling process. The three-stage After the heat exchange is complete...

Embodiment approach 2

[0075] Embodiment 2: It is a four-stage waste heat recovery system with a serpentine bend, see Figure 13-Figure 18

[0076] When the tail gas discharge pipes and preheating air pipes of boilers or other reactors have sufficient layout space in the height direction and the exhaust gas temperature is high, a four-stage or five-stage waste heat recovery system with serpentine bends can be used, such as Figure 13-Figure 18 shown, with Figure 7 to Figure 12 Compared with the serpentine elbow type three-stage waste heat recovery system shown, it can be seen that the tubeless heat exchanger in this embodiment adopts a serpentine elbow type tubeless heat exchanger with four particle curtain heat exchange units. The number of heat exchange stages is increased, and other components, particle conveying device 5 (pneumatic or mechanical conveying) and its reliability to the system, as well as the flexibility of maintenance and operation, etc. resemblance. I won't go into details her...

Embodiment approach 3

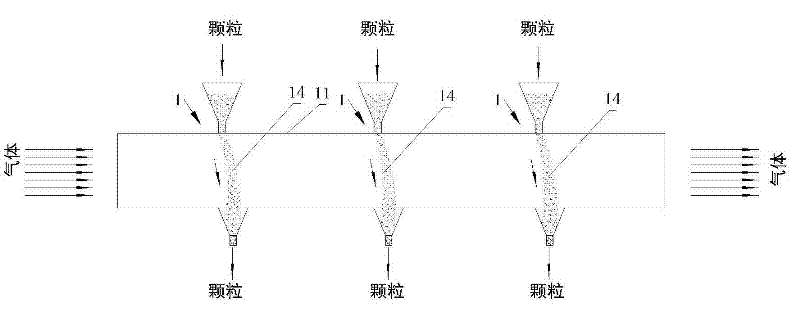

[0077] Embodiment 3: It is a horizontal straight pipe three-stage waste heat recovery system, see Figure 19-Figure 24 .

[0078] When the exhaust temperature of boiler or other reactor is not very high and it is arranged horizontally up and down in the same vertical plane as the air pipe, such as Figure 19-Figure 24 The three-stage waste heat recovery system shown. Compared with the serpentine curved three-stage waste heat recovery system, the particle transfer between the particle curtain heat exchange units at all levels in the horizontal straight pipe three-stage waste heat recovery system is more complicated, and the number of particle transfer devices required is larger.

[0079] from Figure 19 It can be seen that this is a three-stage parallel system. The flue gas tubeless heat exchanger A and the air tubeless heat exchanger B of this system are both in the form of horizontal straight tubes. The particle curtains of the flue gas tubeless heat exchanger exchange heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com