Bagged fermented feed package for livestock and poultry without antibiotics and high live bacteria

An antibiotic-free, fermented feed technology, applied in animal feed, animal feed, applications, etc., can solve problems such as increased production and storage costs, incomplete antigen removal, and insufficient fermentation, and achieves improved feed conversion rate and improved livestock and poultry. Meat quality and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A fermented feed for livestock and poultry without antibiotics and high viable bacteria with a one-way air outlet valve device and a preparation method thereof.

[0022] 1) The composition of the present invention is: fattening livestock and poultry feed: 66% corn, 18% soybean meal, 8% cottonseed meal, 6% bran, and 2% premix.

[0023] 2) The preparation method: crush the above-mentioned raw materials to 30 meshes, mix them uniformly according to the formula ratio, and inoculate the yeast and Bacillus subtilis into the fermenter with aeration device, and expand the culture in a suitable medium 18-24 hours; then inoculate Lactobacillus and Streptococcus lactis into a fermentor without aeration device, and anaerobic expansion in a suitable medium for 44-48 hours. To be tested all reach 10 9 When the density of cfu / g, according to the yeast: Bacillus subtilis: Lactobacillus: Streptococcus lactis = 20-25%: 20-25%: 25-30%: 25: 30%, mix well, then dilute with sterile water To grea...

Embodiment 2

[0025] A fermented feed for livestock and poultry without antibiotics and high viable bacteria with a one-way air outlet valve device and a preparation method thereof.

[0026] 1) The composition of the present invention is: dairy livestock and poultry feed: 66% corn, 18% soybean meal, 8% cottonseed meal, 4% bran, and 4% premix.

[0027] 2) The preparation method: crush the above-mentioned raw materials to 60 meshes, and mix them evenly according to the formula ratio for use; respectively inoculate yeast and Bacillus subtilis into a fermentation tank with aeration device, and expand the culture in a suitable medium 18-24 hours; then inoculate Lactobacillus and Streptococcus lactis into a fermentor without aeration device, and anaerobic expansion in a suitable medium for 44-48 hours. To be tested all reach 10 9 When the density of cfu / g, according to the yeast: Bacillus subtilis: Lactobacillus: Streptococcus lactis = 20-25%: 20-25%: 25-30%: 25: 30%, mix well, then dilute with steril...

Embodiment 3

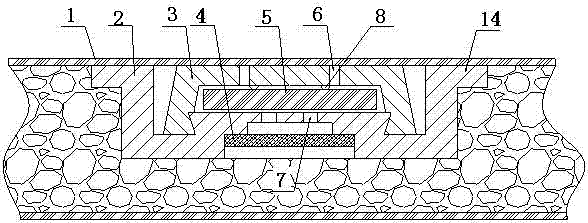

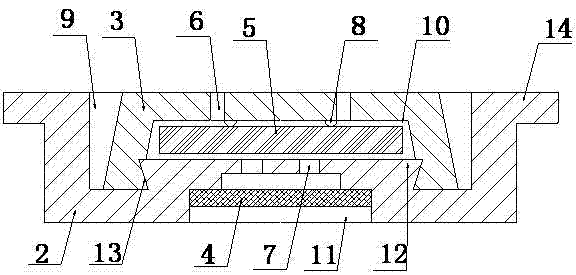

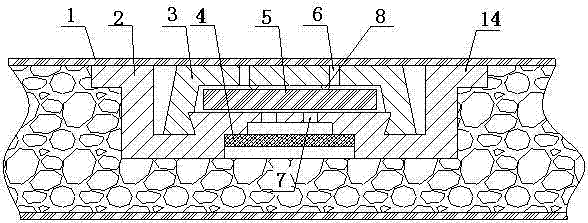

[0029] Such as figure 1 As shown, the packaging bag of the one-way air outlet valve device in the above-mentioned embodiment 1 and embodiment 2, the packaging bag is a PE composite packaging bag, and the film used is a 5-layer composite film 1. Such as figure 2 As shown, the one-way air outlet valve device includes a valve seat 2 and a valve cover 3. The bottom of the valve seat 2 is provided with an annular bonding part 14 which is thermally bonded to the inside of the packaging bag; A first notch 9 is provided in the middle of the bonding portion 14, and a truncated cone-shaped boss 12 is provided in the first notch 9. The valve cover 3 is buckled on the cone-shaped boss 12, and the valve cover 3 is circumferentially inside The wall is provided with an annular chute 13, and the annular chute 13 is matched with the truncated boss 12. An internal cavity 10 is formed between the valve cover 3 and the truncated cone-shaped boss 12. The internal cavity 10 is provided with a silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com