Halogen-free flame retardant material with high heat deformation and preparation method thereof

A flame retardant material and high heat technology, applied in the field of flame retardant materials, can solve the problems of poor dimensional stability, high glass transition temperature, long molding cycle, etc., achieve good mechanical properties, simplify the preparation process, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

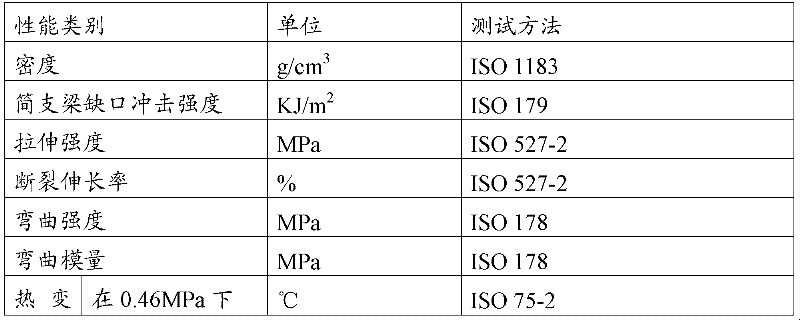

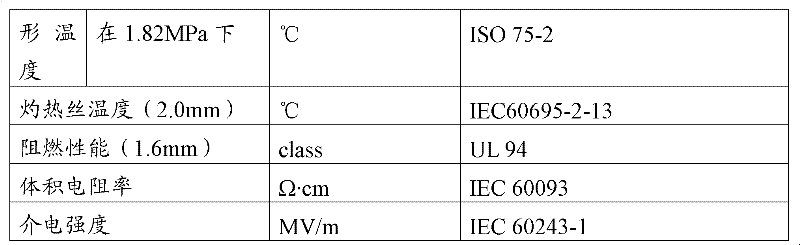

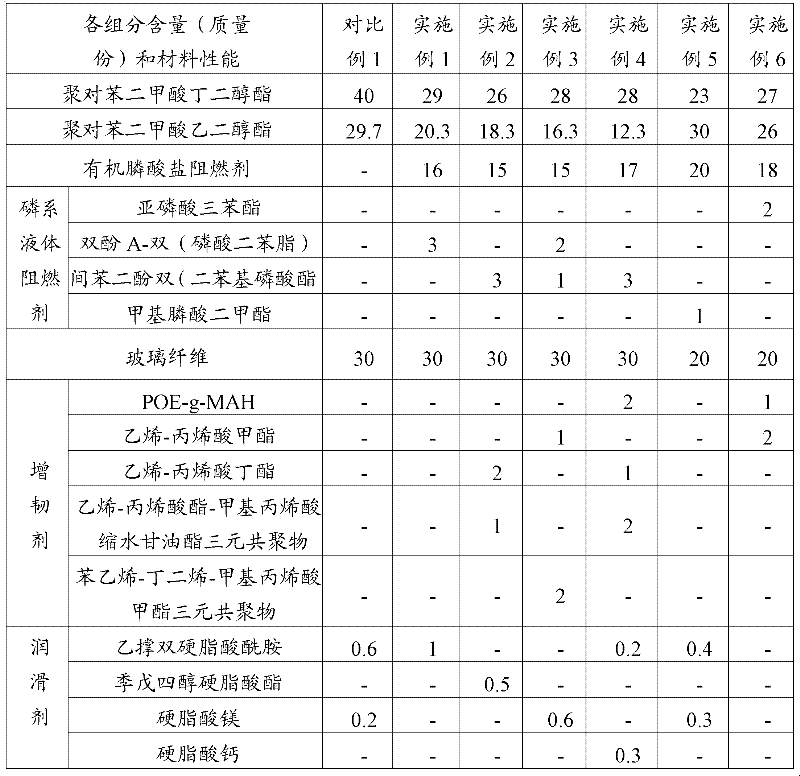

Examples

Embodiment 1

[0038] Step 1. According to the content of each component specified in Table 2, the following components are mixed: organic phosphate flame retardant, phosphorus liquid flame retardant, toughening agent, lubricant, antioxidant, inorganic oxide, silane Stir the coupling agent at 70-90°C at high speed for 4-6 minutes to make it evenly mixed to form the first mixture;

[0039] Step 2, according to the content of each component specified in Table 2, the following components: polybutylene terephthalate, polyethylene terephthalate, mixed under low-speed stirring conditions to form the second mixture;

[0040] Step 3, stirring the first mixture and the second mixture at a low speed for 5-8 minutes to form a granular mixture;

[0041] Step 4, the granular mixture and the glass fiber with the specified content in Table 2 are formed into a molten mixture under the conditions of 200-260°C, 320-400RPM, and 0.04-0.075MPa vacuum, and 60- Cooling at a temperature of 80°C gave a solid produ...

Embodiment 2

[0045] The method of Example 1 was repeated according to the content of each component specified in Table 2, and the performance of the solid product prepared in this example was measured according to the standards described in Table 1. See Table 2 for the measurement results.

Embodiment 3

[0047] The method of Example 1 was repeated according to the content of each component specified in Table 2, and the performance of the solid product prepared in this example was measured according to the standards described in Table 1. See Table 2 for the measurement results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com