mg-based structural member

A technology for structural components and substrates, applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of large anodic oxidation power consumption, etc., achieve waste liquid cost reduction, corrosion inhibition, lighten Effect of Environmental Load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] In Table 1, for 50mM Ca-EDTA / 50mM KH 2 PO 4 In the solution whose pH was adjusted by adding 0, 1 / 40, 1 / 20 or 3 / 40 1N NaOH solution to the aqueous solution, the pure magnesium whose surface was processed with a 0.1 μm alumina grinding film was used as a base material to be immersed in a 95 ℃ for 8 hours to prepare samples A to D.

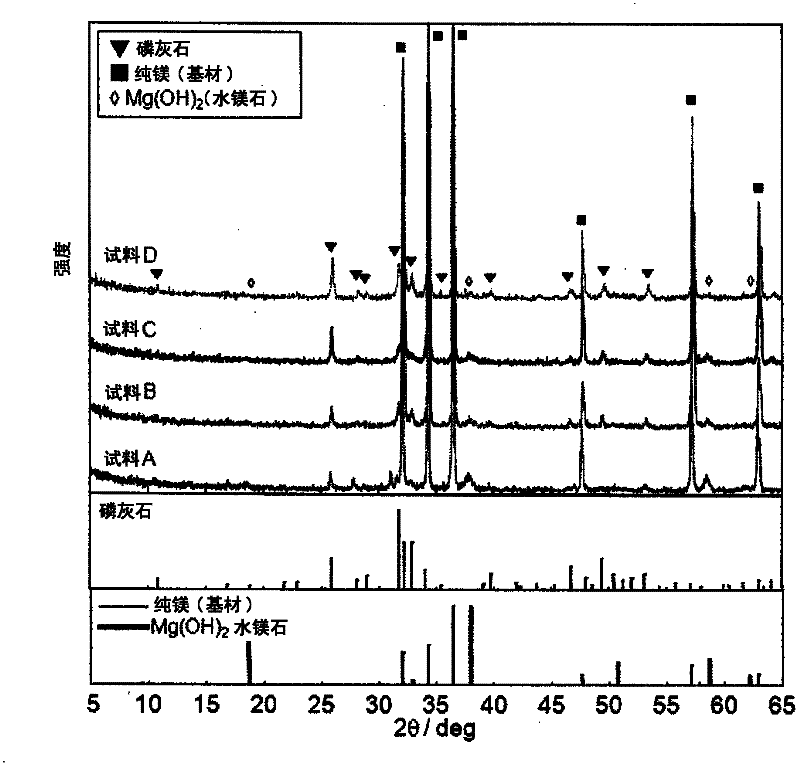

[0060] figure 1 The XRD patterns of the treated samples A to D are shown in . In any sample, hydroxyapatite (HAp) and Mg(OH) were observed 2 (Brucite (Brucite) type) peak. As the pH of the treatment solution increased, the peak intensity of HAp increased and the Mg(OH) 2 (Brucite-type Brucite) has a reduced peak strength.

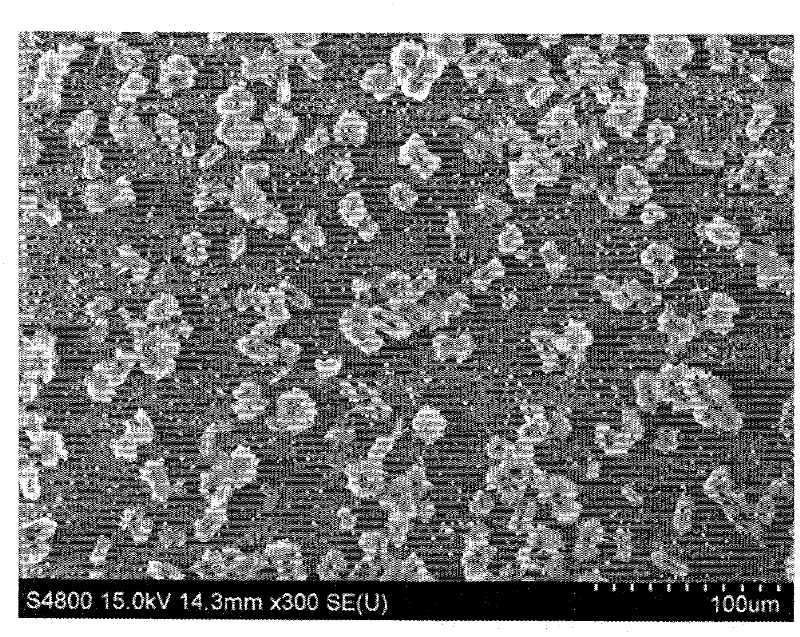

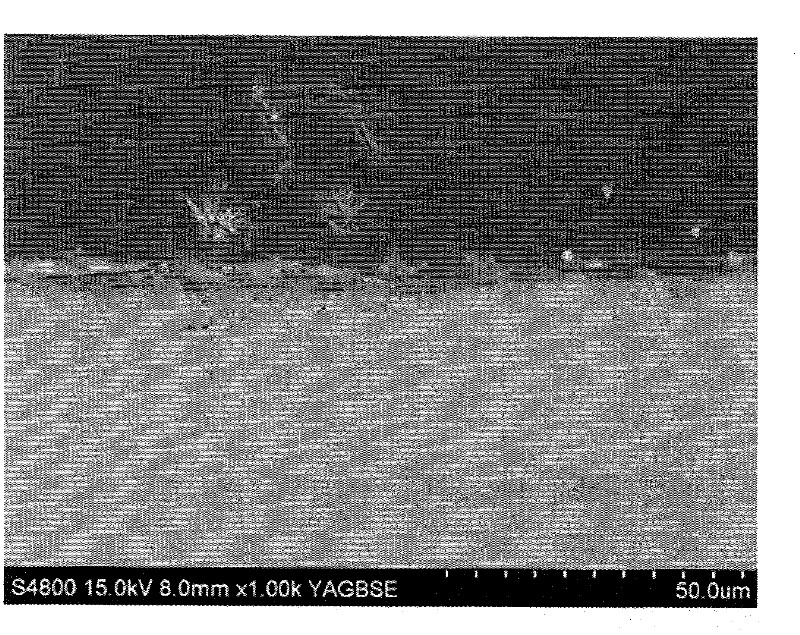

[0061] Electron micrographs of the surfaces and sections of samples B and C are shown in Figure 2-5 middle. In all samples, it was confirmed that the surface was uniformly covered with apatite crystals. Apatite is a plate-shaped or needle-shaped crystal with a diameter of about 1 μm to 10 μm. According to cross-s...

Embodiment 2

[0066] In Table 2, 50mM Ca-EDTA / 50mM KH with pH adjusted by adding 1 / 40 of 1N NaOH 2 PO 4 In the aqueous solution, pure magnesium subjected to the same surface treatment as in Example 1 was dipped as a substrate, and left to stand at 95° C. for 24, 96, and 168 hours to prepare samples E to G. In addition, in Table 2, 50 mM Ca-EDTA / 50 mM KH with pH adjusted by adding 1 / 20 of 1 N NaOH 2 PO 4 In the aqueous solution, pure magnesium subjected to the same surface treatment as in Example 1 was dipped as a substrate, and left to stand at 95° C. for 2, 4, 16, 24, 96, and 168 hours to prepare samples H to M. Figure 6 shows the XRD patterns of samples H and I treated with pH 7.1-7.4 solutions, Figure 7 The XRD pattern of the surface of the samples K-M processed with the solution of pH7.1-7.4 is shown in FIG. The peak of HAp can be observed at any treatment time, and Mg(OH) is also observed in the sample with a long treatment time 2 (brucite) peak. On the other hand, in sample H ...

Embodiment 3

[0073] In Table 3, at 250 mM Ca-EDTA / 250 mM KH 2 PO 4 Add 1 / 40, 1 / 20 or 3 / 40 1N NaOH solution to the aqueous solution and adjust the pH in the aqueous solution, will carry out the pure magnesium that has carried out the same surface processing as Example 1 as a base material, impregnate, static at 95 ℃. Set aside for 8 hours to make samples N to P. The concentrations of phosphate ions and calcium ions in this treatment solution are 5 times that of the solutions used in Example 1 and Example 2.

[0074] Figure 9 The XRD patterns of the processed samples N to P are shown in . The peak of HAp was observed in any sample. The peak intensity of HAp increased as the pH of the treatment solution increased. Mg(OH) 2 The peak of (brucite) was observed in samples O and P, but was not clearly observed in sample N in which the pH of the treatment solution was relatively low. In addition, the Mg(OH) of samples O and P 2 The peak value of is very small compared with samples A to D. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com