Method for preparing optically active poly(alkyl-aryl) silane

An alkylarylsilane and optically active technology, which is applied in the field of preparation of polyalkylarylsilane, can solve the problems of difficulty in preparation, limited synthesis method, and high synthesis cost of dichlorosilane monomer, and achieves simple operation method and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

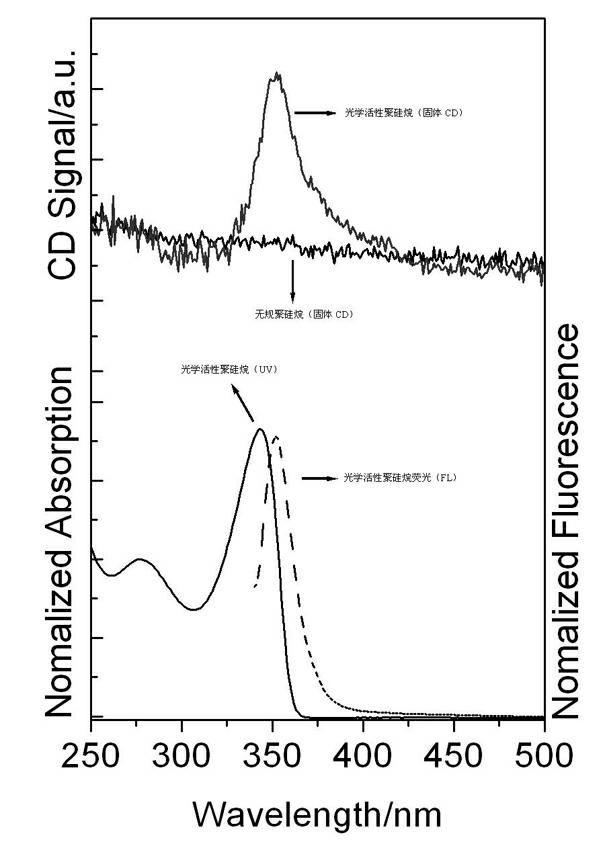

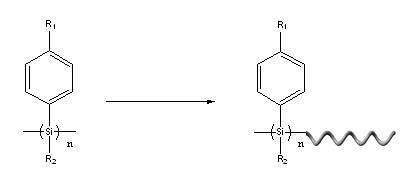

Embodiment 1

[0029] Under the protection of argon, the non-optically active polysilane poly-4-methylphenylmethylsilane (134 mg, the molar number of repeating units is 1 mmol), the chiral diamine compound (-)-sparteine(a) (23 mg, 0.1 mmol) dissolved in 20ml tetrahydrofuran. The solution was cooled to -78 0 C, slowly drop tert-butyllithium (0.1mmol), at -78 0 C for 1 hour. The reaction was quenched by adding saturated ammonium chloride solution (1 ml) dropwise, extracted with toluene three times (3×10 mL), and the organic layer was washed three times with saturated saline solution (3×10 mL). The organic layer was dried over anhydrous magnesium sulfate, filtered, evaporated the solvent, dissolved in anhydrous tetrahydrofuran (1 mL), and reprecipitated with absolute ethanol to obtain 124 mg of optically active poly-4-methylphenylmethylsilane. The result is an average molecular weight distribution of M w / M n = 1.3, the average molecular weight is M n = 13000 of methylphenyl polysilane,...

Embodiment 2

[0032] Under nitrogen protection, the non-optically active polysilane poly-4-ethylphenylmethylsilane (148 mg, the molar number of repeating units is 1 mmol), the chiral diamine compound (-)-sparteine (a) (2.3 mg , 0.01mmol) dissolved in 20ml 1,2-dimethoxyethane. The solution was cooled to -100 0 C, slowly drop n-butyllithium (0.1mmol), at -100 0 C was reacted for 0.5 hours. The reaction was quenched by adding saturated ammonium chloride solution (1 ml) dropwise, extracted with dichloromethane (3×10 mL), and the organic layer was washed three times with saturated saline solution (3×10 mL). The organic layer was dried over anhydrous magnesium sulfate, filtered, the solvent was distilled off, dissolved in anhydrous chloroform (1 mL), and reprecipitated with anhydrous methanol to obtain 127 mg of optically active poly-4-ethylphenylmethylsilane. The result is an average molecular weight distribution of M w / M n = 1.2, the average molecular weight is M n = 12908 of methylp...

Embodiment 3

[0034] Under the protection of argon, the non-optically active polysilane poly-4-methylphenylethylsilane (148 mg, the molar number of repeating units is 1 mmol), the chiral diamine compound (-)-sparteine (a) (230 mg, 1mmol) dissolved in 20ml benzene. The solution cools down to 0 0 C, slowly drop sec-butyllithium (0.1mmol), at 0 0 C for 1 hour. The reaction was quenched by adding saturated ammonium chloride solution (0.5 ml) dropwise, extracted twice with chloroform (2×10 mL), and the organic layer was washed three times with saturated saline solution (3×10 mL). The organic layer was dried over anhydrous magnesium sulfate, filtered, evaporated the solvent, dissolved in anhydrous benzene (1 mL), and reprecipitated with anhydrous ethanol to obtain 127 mg of optically active poly-4-methylphenylethylsilane. The result is an average molecular weight distribution of M w / M n = 1.4, the average molecular weight is M n = 12963 of methylphenylpolysilane, the yield is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com