Composite substrate, preparation method of composite substrate and method for preparing single crystal thick film through hetero-epitaxy

A composite substrate and a manufacturing method technology, applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as unfavorable industrialization, cracking of sapphire substrates, gallium nitride single crystal thick films and sapphire substrates Problems such as warping of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

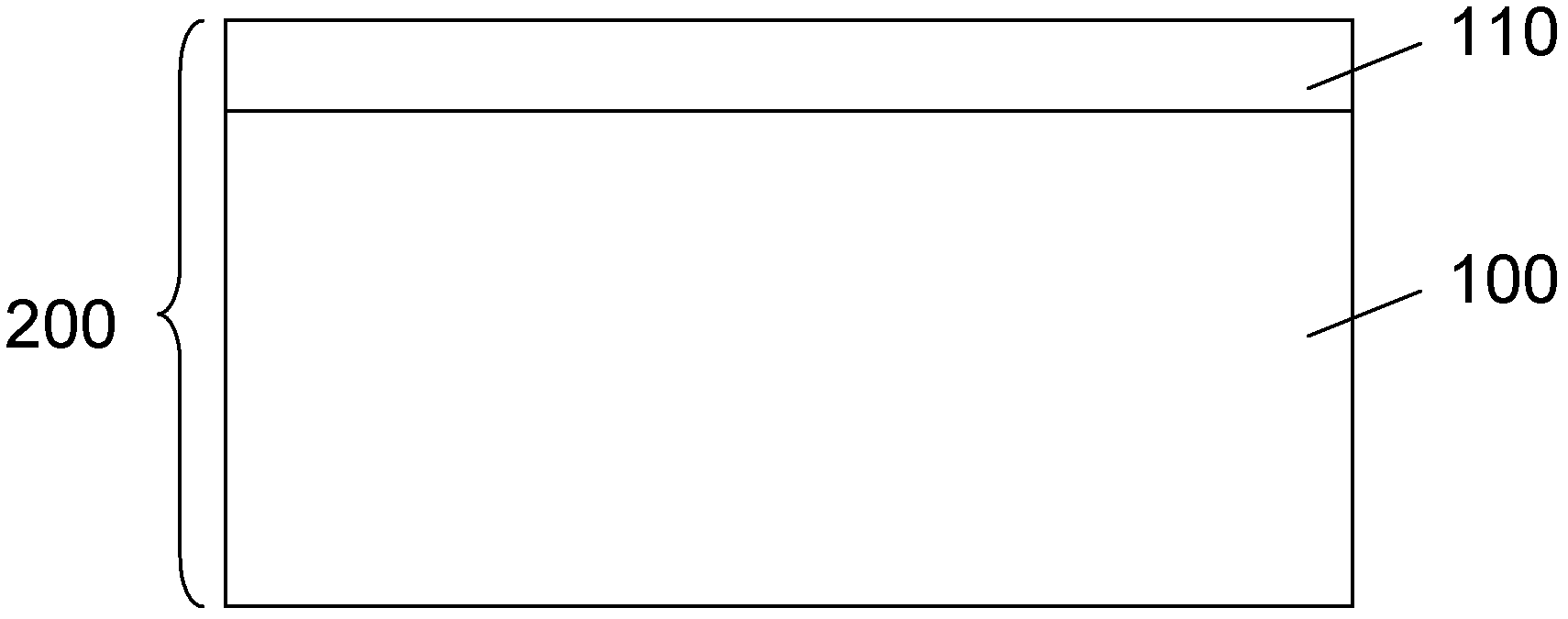

[0038] In this example, refer to figure 1 As shown, the composite substrate 200 includes a foreign substrate 100 and a buffer layer 110 on the foreign substrate 100, and the thickness of the foreign substrate 100 is 0.5-13 millimeters.

[0039] More preferably, the thickness of the foreign substrate 100 is 3-8 mm.

[0040] In the present invention, heterogeneous substrate refers to non-nitride substrates such as sapphire, silicon carbide, single crystal silicon, zinc oxide, etc., and the buffer layer is a nitride film, such as aluminum nitride, gallium nitride or gallium nitride alloy, etc. , the thickness of the buffer layer may be less than 50 microns, more preferably, less than 10 microns.

[0041] In the present invention, the composite substrate is used for the epitaxial growth of a group III nitride semiconductor single crystal thick film, such as gallium nitride, aluminum nitride, indium nitride and the like.

[0042] In the composite substrate 200 in this embodiment,...

Embodiment 2

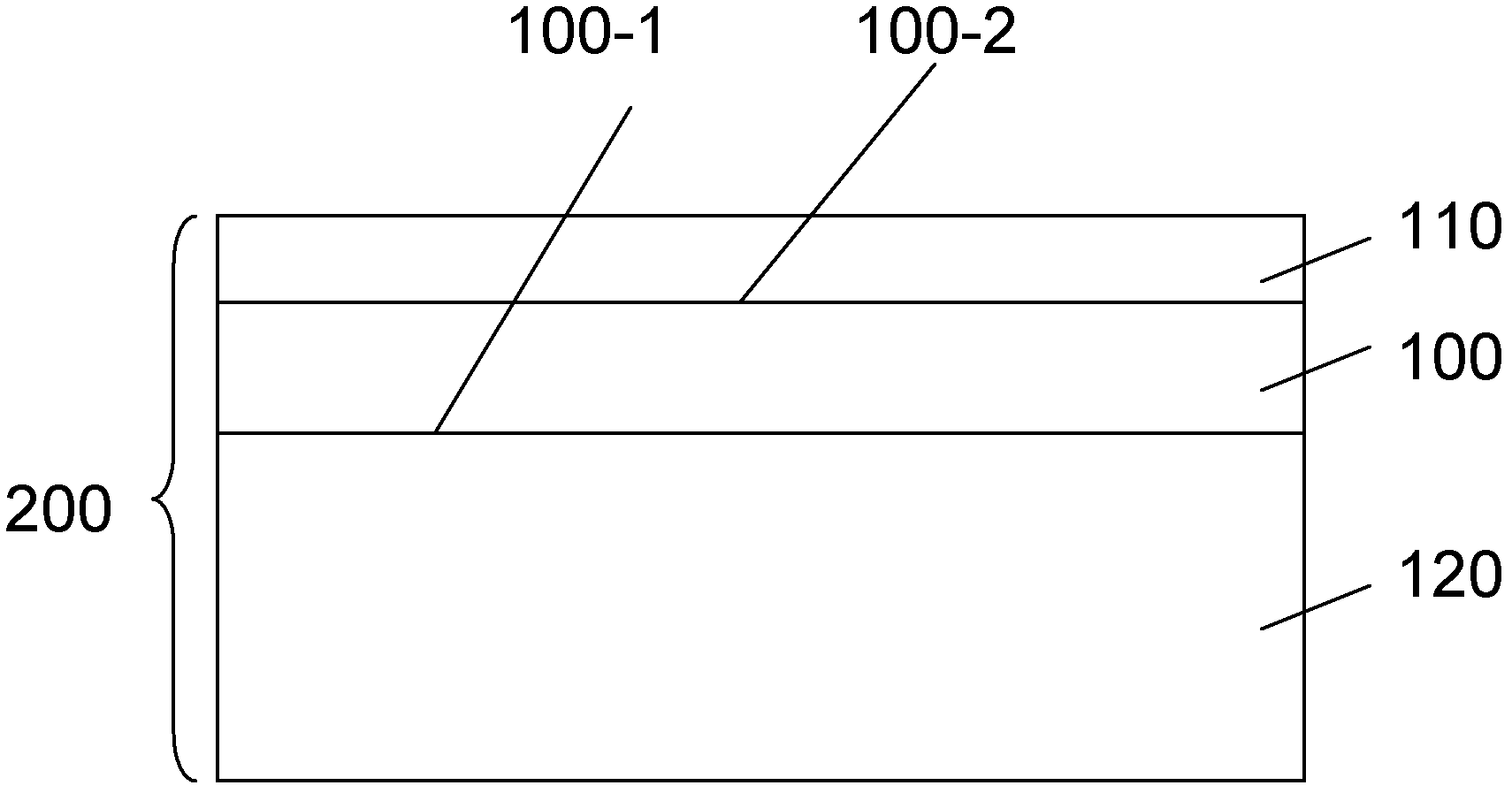

[0050] In this example, refer to figure 2 As shown, the composite substrate 200 includes: a first substrate 120, a foreign substrate 100 on the first substrate 120, and a buffer layer 110 on the foreign substrate 100, wherein the first substrate 120 and the foreign substrate 120 are The heterogeneous substrate 100 has the same thermal expansion coefficient, or the thermal expansion coefficient difference between the first substrate 120 and the heterogeneous substrate 100 is less than 60%, and the thickness of the first substrate 120 is 0.5 to 13 mm.

[0051] More preferably, the first base 120 has a thickness of 3 to 8 mm.

[0052] In this embodiment, the first base 120 and the foreign substrate 100 may have the same coefficient of thermal expansion, that is, the first base and the foreign substrate are made of the same substrate material, for example, the foreign Both the solid substrate and the first base are sapphire, silicon carbide, single crystal silicon or zinc oxide....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com