Diazinon emulsifiable granules and preparation method thereof

A technology of diazinon and emulsifier, which is applied in the fields of botanical equipment and methods, insecticides, acaricides, etc., can solve the problems of waste of petroleum resources, quick effect, lasting effect, insufficient environmental protection, environmental pollution and the like , to achieve high HLB value, maintain colloidal stability, and facilitate packaging and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

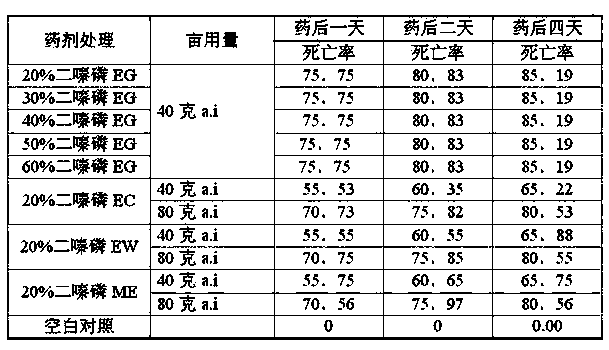

Examples

Embodiment 1

[0015] Example 1: 20% diazinon emulsifiable granules.

[0016] Liquid diazinon 20%, emulsifier YUS-FS1 (non-ionic phosphate, produced by Takemoto Oil) 5%, water-soluble polymer polyvinyl alcohol (PVA) 8%, and the balance is supplemented by carrier ammonium bicarbonate. First, mix diazinon and emulsifier evenly, then add the mixed diazinon into 10% polyvinyl alcohol (PVA) aqueous solution (PVA and water are made into an aqueous solution at a ratio of 1:10), mix evenly to obtain a viscous Emulsion, and the carrier ammonium bicarbonate is added to the viscous emulsion to obtain a pre-granulation mixture, which is finally granulated and dried.

Embodiment 2

[0017] Example 2: 30% diazinon emulsifiable granules.

[0018] Liquid diazinon 30%, emulsifier YUS-SB75 (nonionic and anionic mixed surfactant, produced by Takemoto Oil) 8%, water-soluble polymer carboxymethyl starch sodium (CMS) 10%, the balance is carrier sodium benzoate make up. First, mix diazinon and emulsifier evenly, then add the mixed diazinon into 8% carboxymethyl starch sodium (CMS) aqueous solution (CMS and water are made into an aqueous solution at a ratio of 1:8), mix evenly to obtain a viscous Thick emulsion, then adding the carrier sodium benzoate to the viscous emulsion to obtain a pre-granulated mixture, finally granulated and dried.

Embodiment 3

[0019] Example 3: 40% diazinon emulsifiable granules.

[0020] Liquid diazinon 40%, emulsifier YUS-CH7000 (nonionic and anionic mixed surfactant, produced by Takemoto Oil) 9%, water-soluble polymer sodium carboxymethylcellulose (CMC) 12%, the balance is carrier sulfuric acid Ammonium supplementation. First mix diazinon and emulsifier evenly, then the mixed diazinon is added to 12% carboxymethylcellulose sodium (CMC) aqueous solution (CMC and water are made into an aqueous solution at 1:12), and mix evenly to obtain A viscous emulsion, and the carrier ammonium sulfate is added to the viscous emulsion to obtain a pre-granulated mixture, which is finally granulated and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com