Calcium sulfate whisker modified polyphenylene sulfide composite material and preparation method thereof

A technology of calcium sulfate whiskers and polyphenylene sulfide, applied in the field of polyphenylene sulfide composite materials and its preparation process, can solve the problems of reducing the thermal physical properties of PPS and limiting the application of PPS, and achieve excellent thermal physical properties and low cost , Good insulation and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

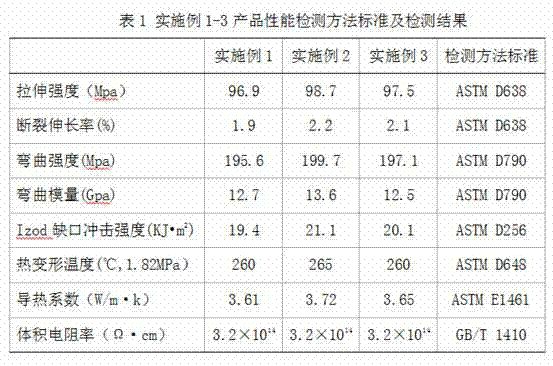

Examples

Embodiment 1

[0023] The calcium sulfate whisker modified polyphenylene sulfide composite material of this embodiment is made of the following parts by weight: 48.5 parts of polyphenylene sulfide (PPS), 10 parts of calcium sulfate whiskers with a diameter of 10-20 μm, and a diameter of 10 parts. -300μm thermal conductive filler 35 parts of magnesium oxide, 5 parts of silane coupling agent, 0.5 parts of antioxidant 1010, 1 part of lubricant calcium stearate.

[0024] Preparation:

[0025] (1) Pretreatment of thermally conductive filler magnesium oxide: 35 parts by weight of thermally conductive filler magnesium oxide with a diameter of 10-300μm are added to the high-speed mixer, and then 3 parts by weight of silane coupling agent are added, and mixed for 10 minutes;

[0026] (2) Pretreatment of calcium sulfate whiskers: add 10 parts by weight of calcium sulfate whiskers with a diameter of 10-20μm and 2 parts by weight of silane coupling agent to a high-speed mixer and mix for 10 minutes to obtain m...

Embodiment 2

[0033] The calcium sulfate whisker modified polyphenylene sulfide composite material of this embodiment is made of the following parts by weight: 43.5 parts of polyphenylene sulfide (PPS), 15 parts of calcium sulfate whiskers with a diameter of 10-20 μm, and a diameter of 10 -35 parts of 300μm thermally conductive filler alumina, 5 parts of titanate coupling agent, 0.5 parts of antioxidant 1010, 1 part of lubricant zinc stearate.

[0034] Preparation:

[0035] (1) Pretreatment of thermally conductive filler alumina: add 35 parts by weight of thermally conductive filler alumina with a diameter of 10-300 μm to the high-speed mixer, then add 3 parts by weight of titanate coupling agent, and mix for 10 minutes;

[0036] (2) Pretreatment of calcium sulfate whiskers: 15 parts by weight of calcium sulfate whiskers with a diameter of 10-20μm and 2 parts by weight of titanate coupling agent are added to a high-speed mixer and mixed for 10 minutes to obtain modified sulfuric acid Calcium whis...

Embodiment 3

[0043] The calcium sulfate whisker modified polyphenylene sulfide composite material of this embodiment is made of the following parts by weight: 38.5 parts of polyphenylene sulfide (PPS), 20 parts of calcium sulfate whiskers with a diameter of 10-20 μm, and a diameter of 10 parts. -300μm thermal conductive filler 35 parts of aluminum nitride, 5 parts of aluminate coupling agent, 0.5 parts of antioxidant 1010, 1 part of lubricant calcium stearate.

[0044] Preparation:

[0045] (1) Pretreatment of thermally conductive filler aluminum nitride: add 35 parts by weight of thermally conductive filler aluminum nitride with a diameter of 10-300 μm to the high-speed mixer, then add 3 parts by weight of aluminate coupling agent, and mix for 10 minutes;

[0046] (2) Pretreatment of calcium sulfate whiskers: add 20 parts by weight of calcium sulfate whiskers with a diameter of 10-20 μm and 2 parts by weight of aluminate coupling agent to a high-speed mixer and mix for 10 minutes to obtain modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com