Composite luminescent material and preparation method thereof and light emitting diode (LED) luminescent device

A technology of luminescent materials and packaging materials, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limiting the luminous efficiency of white LEDs, limited luminous efficiency, non-radiative transitions, etc., to accelerate the radiative transition rate and improve the internal quantum efficiency. , the effect of enhancing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

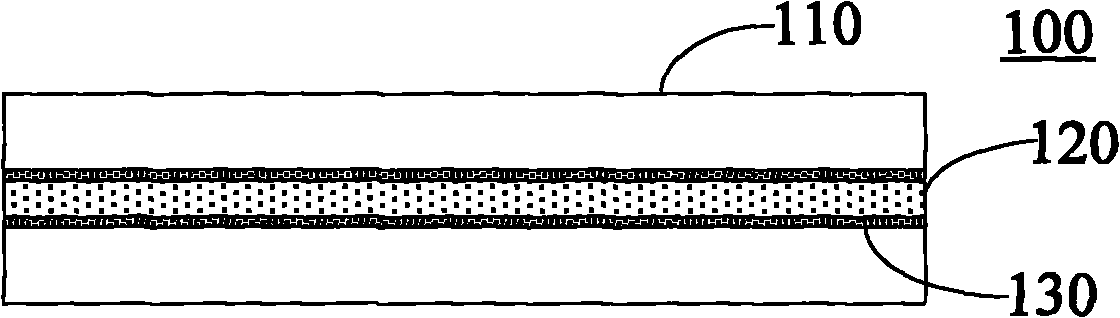

[0025] The multiple layers of glass 110 and the fluorescent layer 120 in Embodiment 1 are designed in one piece, and the multiple layers of glass 110 are softened and fused together to sandwich the fluorescent layer 120 .

[0026] The material of the metal layer 130 in Embodiment 1 can be selected from metals with good chemical stability, such as metals that are not easily oxidized and corroded, preferably gold, silver, aluminum, copper, titanium, iron, nickel, cobalt, chromium, platinum, palladium, magnesium , zinc, and more preferably at least one of gold, silver, and aluminum, such as a single metal, or an alloy of two or more of the above three metals, such as It is silver aluminum alloy or gold aluminum alloy, wherein the weight fraction of silver or gold is more than 70%.

[0027] The fluorescent powder in the fluorescent layer 120 of embodiment 1 is selected from at least one of red fluorescent powder, yellow fluorescent powder, and green fluorescent powder excited by b...

Embodiment 2

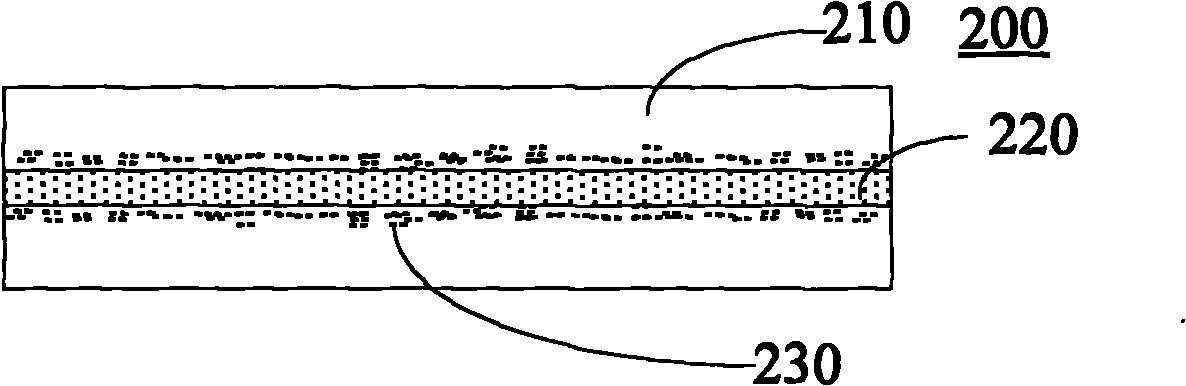

[0038] The preparation process of the composite luminescent material 200 in Example 2 is substantially the same as the preparation process of the composite luminescent material 100 in Example 1, the difference is that in the process of preparing the glass containing the metal layer in step S2, the glass is firstly implanted with ions. Implanting metal ions, the implantation amount of metal ions is preferably 1.7×10-10 mol / cm 2 ~1.7×10 -7 mol / cm 2 , the injection voltage is preferably 20kV ~ 100kV, and a large number of metal ions are formed within the range of less than 200 nanometers from the surface of the glass; then the glass is placed in a reducing atmosphere for annealing, so that the metal ions are reduced to simple substances. During the reduction process Elemental metals may agglomerate, and metal nanoparticles are precipitated inside or on the surface of the glass.

[0039] It can be understood that as long as the interior of at least one layer of glass in the comp...

Embodiment 3

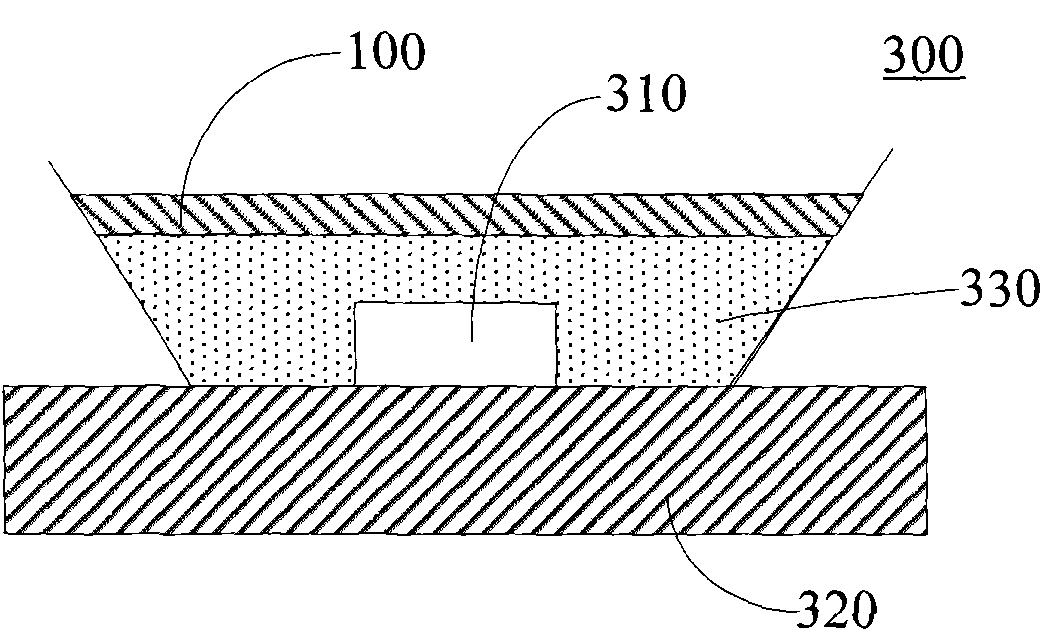

[0049] In this embodiment, the glass composition used is tellurate glass, the glass is ground and polished to form a glass with a thickness of 1mm, and the phosphor is yellow phosphor silicate (provided by Dalian Luming Luminescent Technology Co., Ltd. , the product model is LMS-560-B). The structure of the tellurate phosphor-glass composite luminescent material containing the metal micro-nano structure metal layer is as follows Figure 5 As shown, the preparation process is as follows: First, a layer of gold film with a thickness of 5 nm is formed on the surface of glass 501 and 502 by magnetron sputtering method, and the glass 501 and 502 are placed in a vacuum degree of less than 1×10 -3 Under a vacuum environment of Pa, annealing at a temperature of 500° C. for half an hour, and then cooling to room temperature, the gold film layers 503 and 504 on the glasses 501 and 502 are obtained, and the deposition method is used on the glasses 501 and 504 with metal layers respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com