Preparation method of composite current collector and application of composite current collector in lithium ion flow battery

A flow battery, lithium ion technology, applied in the field of electrochemical applications, can solve the problem of high interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of carbon nanotube-copper flake composite collector:

[0029] (1) 2 grams of multi-walled carbon nanotubes were refluxed at 70° C. for 8 hours in 300 milliliters of sulfuric acid and nitric acid mixed solution (volume ratio 3: 1, purity respectively 96%, 70%), filtered, washed with deionized water, 100 ℃ vacuum (≤-0.01MPa) drying for 10 hours to obtain carbon nanotubes with carboxyl groups (-COOH) on the surface;

[0030] (2) Weigh 1 gram of carbon nanotubes with carboxyl groups (-COOH) on the surface, reflux in 100 ml of thionyl chloride at 78°C for 12 hours, evaporate the remaining thionyl chloride, and then add 80 ml of ethylenediamine Anhydrous toluene solution (concentration 0.02 g / ml) was reacted at 70°C for 25 hours, filtered, washed with ethanol and deionized water, and dried under vacuum (≤-0.01MPa) at 50°C for 23 hours to obtain 2 ) of carbon nanotubes.

[0031] (3) The above-mentioned carbon nanotubes with carboxyl (-COOH) and amin...

Embodiment 2

[0035] Embodiment 2: Preparation of carbon nanotube-aluminum flake composite current collector:

[0036] (1) 2 grams of multi-walled carbon nanotubes were refluxed at 75° C. for 10 hours in 300 milliliters of sulfuric acid and nitric acid mixed solution (volume ratio 3: 1, purity respectively 96%, 70%), filtered, washed with deionized water, 100 ℃ vacuum (≤-0.01MPa) drying for 6 hours to obtain carbon nanotubes with carboxyl groups (-COOH) on the surface;

[0037] (2) Weigh 1 gram of carbon nanotubes with carboxyl groups (-COOH) on the surface and reflux at 78°C in 100 ml of thionyl chloride for 10 hours, evaporate the remaining thionyl chloride, and then add 80 ml of ethylenediamine Anhydrous toluene solution (concentration 0.02 g / ml) was reacted at 70°C for 20 hours, filtered, washed with ethanol and deionized water, and dried under vacuum (≤-0.01MPa) at 50°C for 18 hours to obtain an amino group (-NH 2 ) of carbon nanotubes.

[0038] (3) The above-mentioned carbon nanotub...

Embodiment 3

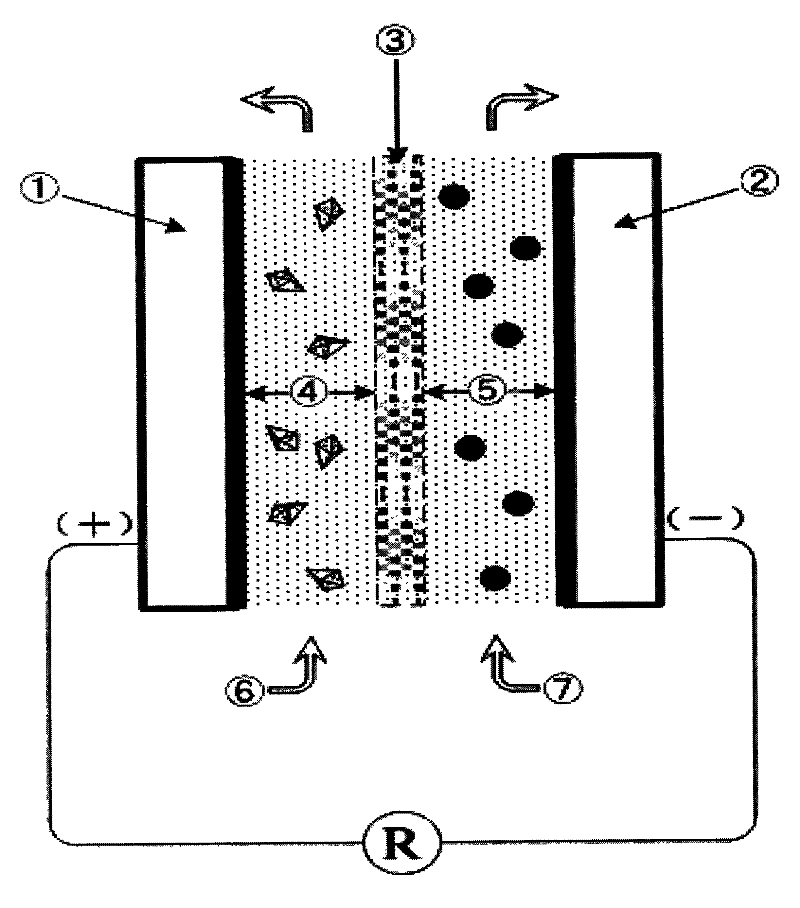

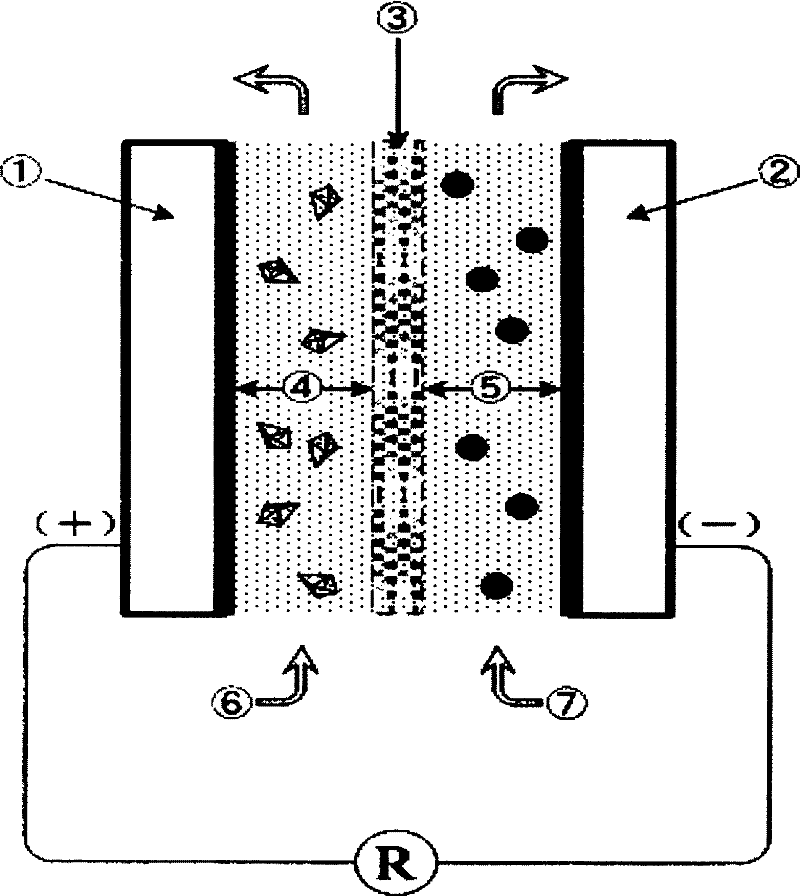

[0042] Example 3: Application of Composite Current Collector in Lithium-ion Flow Batteries

[0043] The carbon nanotube-copper sheet composite collector prepared in Example 1 is the negative electrode collector, the carbon nanotube-aluminum sheet composite collector prepared in Example 2 is the positive electrode collector, and the polypropylene film Celgard 2500 is used as the negative electrode collector. The lithium ion separator, the width of the positive and negative electrode chambers are 3 mm, and related components are assembled into an electrochemical device according to the attached drawings.

[0044] Preparation of positive electrode slurry: under anhydrous, oxygen-free helium atmosphere, 10 g of LiCoO 2 (D50=3um), 1g conductive carbon (Ketjen ECP600JD), 1.2M LiPF 6 About 120 ml of the ethylene carbonate-dimethyl carbonate (3:7) solution was mixed together and sonicated for 30 minutes to form a slurry with a solid-to-liquid volume ratio of 20%.

[0045] Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com