Dicyandiamide production method

A production method, dicyandiamide technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of easy explosion of calcium carbide, large amount of residue and dust, high safety requirements, etc., and achieve production cost The effect of reducing and reducing environmental pressure and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

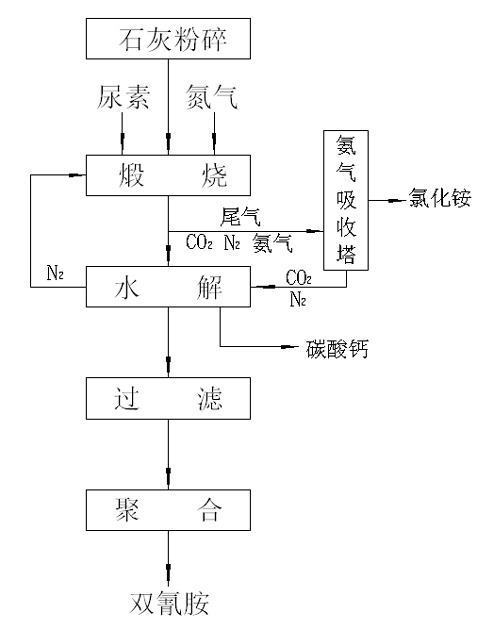

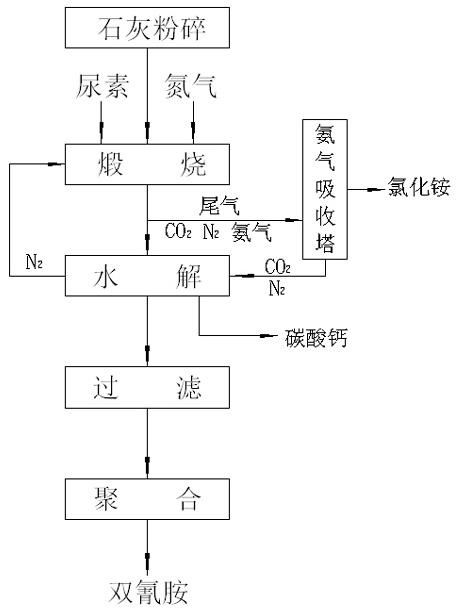

[0021] Such as figure 1 As shown, the lime is now crushed to 20 meshes, mixed evenly according to the weight ratio of urea:lime 1:1, put into the calciner, and heated to about 200-240°C under the protection of nitrogen for calcination for 2 hours, and then heated up After calcining at 650-700°C for 3 hours, a compound mainly containing calcium cyanamide is obtained. The obtained compound mainly containing calcium cyanamide is reacted according to the existing calcium cyanamide hydrolysis and polymerization methods to obtain dicyandiamide. At this time, the effective nitrogen content in the intermediate product calcium cyanamide can reach more than 23%.

Embodiment 2-3

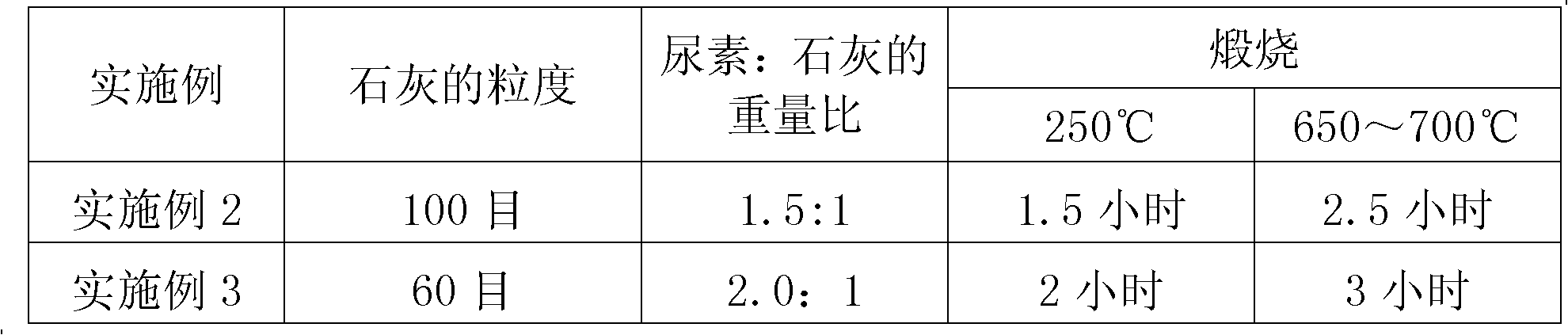

[0023] On the basis of embodiment 1, change the relevant process parameters as follows:

[0024]

[0025] The effective nitrogen content in the intermediate product calcium cyanamide obtained in the above-mentioned embodiment 2 can reach more than 23.5%.

[0026] The effective nitrogen content in the intermediate product calcium cyanamide obtained in the above-mentioned embodiment 3 can reach more than 25%.

[0027] In the above examples 1-3, after recovering the tail gas generated in the calcination process, the tail gas mainly contains ammonia, carbon dioxide and nitrogen that does not participate in the reaction and plays a protective role. The above tail gas is passed through an ammonia absorption tower sprayed with hydrochloric acid to obtain an ammonium chloride solution. Add the obtained calcium cyanamide into the hydrolysis tank, and then pass through the carbon dioxide collected after passing through the ammonia absorption tower, and the nitrogen that does not par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com