ZnO luminous nanoparticles synthesized in polyethylene glycol and preparation method thereof

A nanoparticle and polyethylene glycol technology, applied in the field of nanomaterials, can solve problems such as unsatisfactory stability and limited application, and achieve the effects of simple and efficient preparation method, stable luminescence properties, and stable composition and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

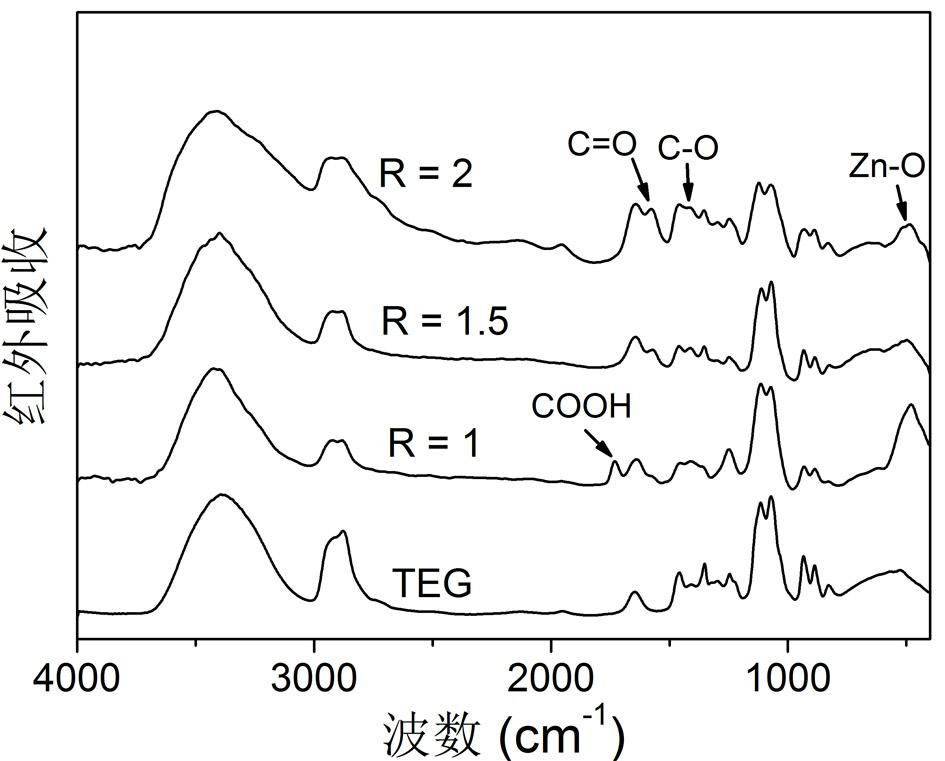

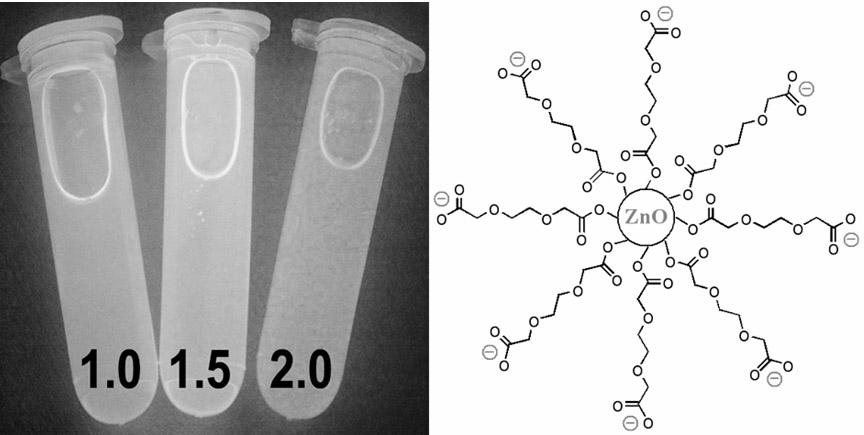

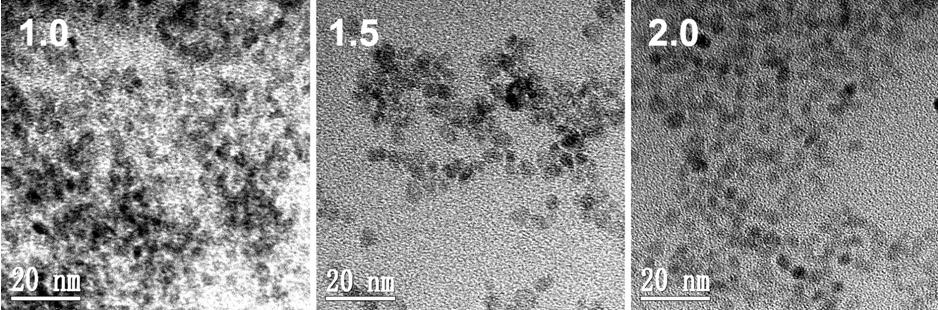

[0024] Example 1 2.2 g of Zn(Ac) 2 2H 2 O and 0.63g of LiOH·H 2 Add O to 100 mL of triethylene glycol (TEG), and use high-speed stirring to help dissolve. At this time, the concentration of zinc acetate is 0.1M, and the molar ratio of lithium hydroxide [LiOH] / [Zn 2+]=1. After reacting at room temperature for 48 hours, ethyl acetate was used as a precipitating agent to obtain a gel of ZnO nanoparticles. After washing the residual mother liquor with ethyl acetate, the ZnO nanoparticle gel was dissolved in a small amount of ethanol, and after complete dissolution, the ZnO nanoparticle was precipitated again with ethyl acetate to obtain pure ZnO nanoparticle. The determination of quantum efficiency adopts rhodamine 6G (quantum efficiency 95%) dissolved in ethanol solution as a benchmark.

[0025] The method utilizes TEG to protect the surface of ZnO and obtains stable ZnO nanoparticles. Under base-catalyzed, air-oxidized conditions, TEG derivatives have been modified onto t...

Embodiment 2

[0026] Example 2 The preparation method is the same as in Example 1, the concentration of zinc acetate in the reaction system is still 0.1 M, but the feed ratio R=1.5 of lithium hydroxide and zinc acetate, and other conditions remain unchanged, finally obtaining ZnO with a luminous wavelength of 511 nanometers and a quantum efficiency of 26 %.

Embodiment 3

[0027] Example 3 The preparation method is the same as in Example 1, the concentration of zinc acetate in the reaction system is still 0.1 M, but the feed ratio R=2 of lithium hydroxide and zinc acetate, and other conditions remain unchanged, finally obtaining ZnO with a luminous wavelength of 482 nanometers and a quantum efficiency of 25 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com