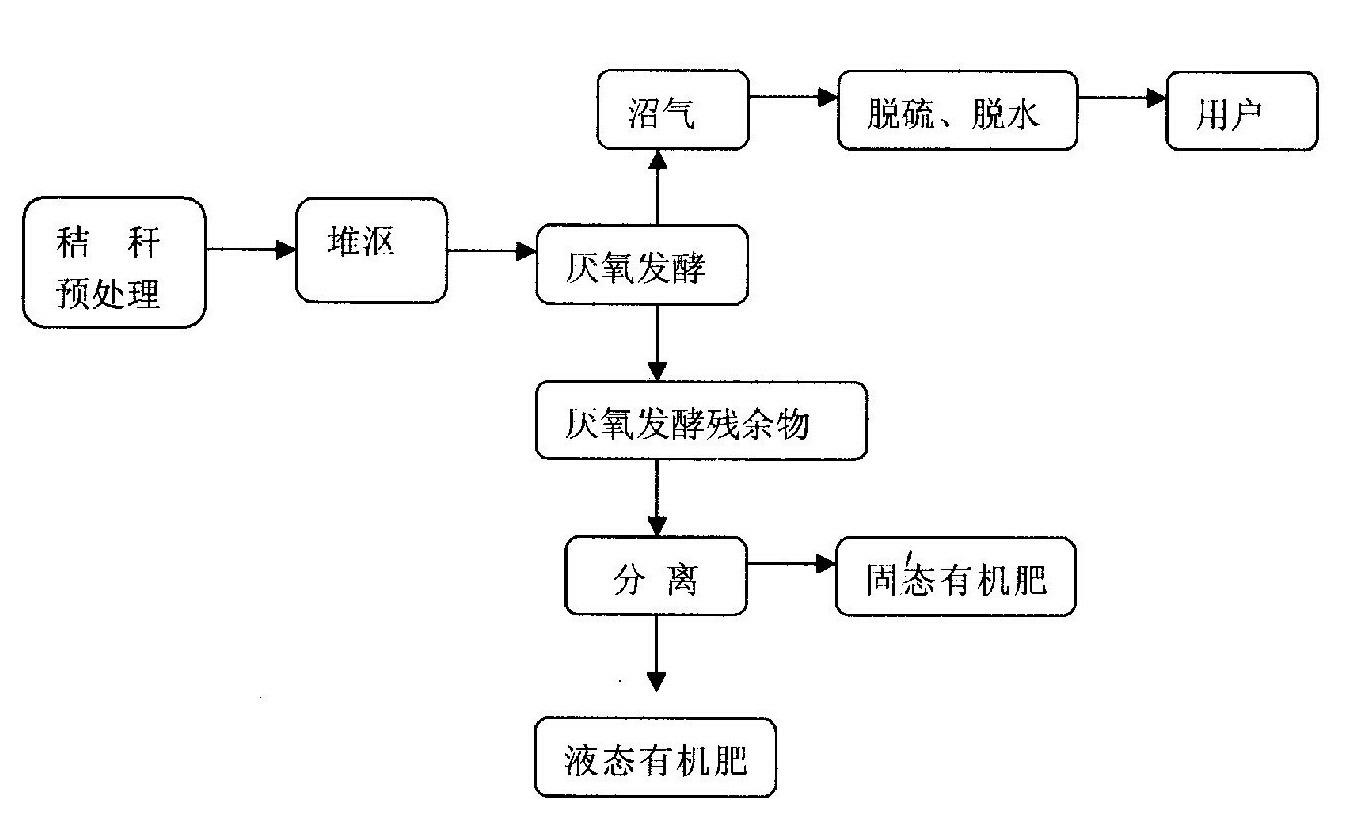

Method for manufacturing biogas and organic fertilizer by straw

A technology of organic fertilizer and straw pulverizer, applied in the direction of organic fertilizer, fertilizer made of biological waste, sewage/sludge fertilizer, etc., can solve the problem that biogas residue and biogas slurry are not well utilized, limit the application of biogas engineering and Promotion, secondary pollution resources and other issues, to achieve the effect of facilitating the formation of soil aggregate structure, facilitating the use of anaerobic microorganisms, and increasing the methane content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

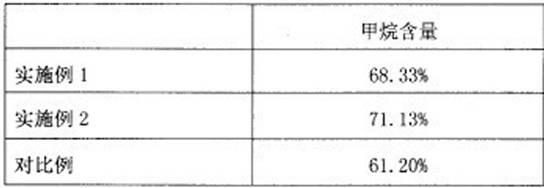

Embodiment 1

[0047] (1) Pretreatment of straw:

[0048] ①Straw crushing:

[0049] The straw is pulverized by a straw pulverizer, and the length of the pulverized straw is 20 mm.

[0051]Add water at a ratio of 1:1 to wet the crushed straw, and turn the straw while adding water to ensure uniform wetting; after the wetting is completed, place the straw for 24 hours to facilitate the straw to fully absorb water.

[0052] ③ Mixing of raw materials:

[0053] Add the compound bacterial agent and ammonium bicarbonate to the wetted straw while stirring well, and add water at the same time, the amount of water added is twice the weight of the straw, so that the moisture content of the straw is 60%; the amount of the compound bacterial agent added is the crop straw 0.25% of the mass, the addition of ammonium bicarbonate should ensure that the C / N of the fermentation feed liquid is 25:1;

[0054] (2) Stack retting of straw:

[0055] Pile the wet straw with a height of 1m...

Embodiment 2

[0062] (1) Pretreatment of straw:

[0063] ①Straw crushing:

[0064] The straw is pulverized by a straw pulverizer, and the length of the pulverized straw is 20 mm.

[0065] ②Straw wetting:

[0066] Add water at a ratio of 1:1 to wet the crushed straw, and turn the straw while adding water to ensure uniform wetting; after the wetting is completed, place the straw for 24 hours to facilitate the straw to fully absorb water.

[0067] ③ Mixing of raw materials:

[0068] Add the compound bacterial agent and ammonium bicarbonate to the wetted straw while stirring well, and add water at the same time, the amount of water added is twice the weight of the straw, so that the moisture content of the straw is 55%. 0.15% of the mass, the addition of ammonium bicarbonate should ensure that the C / N of the fermentation feed liquid is 25:1.

[0069] (2) Stack retting of straw:

[0070] Pile the wet straw with a height of 1.5m. Drill holes with sharp wooden sticks every 20cm on the top of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com