A kind of flexible packaging lithium ion battery

A lithium-ion battery, flexible packaging technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of lifting, loss of blocking water vapor and air, loss, etc., to achieve simple process, good resistance to electrochemical corrosion, The shell is transparent and beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

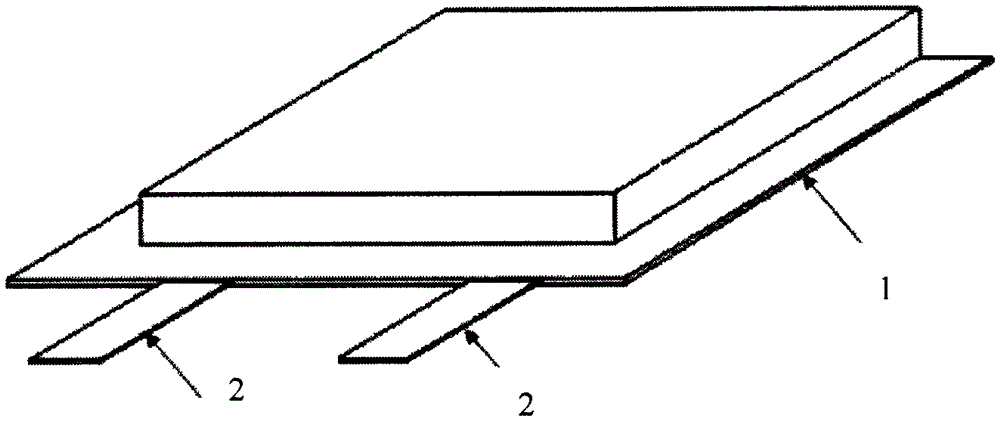

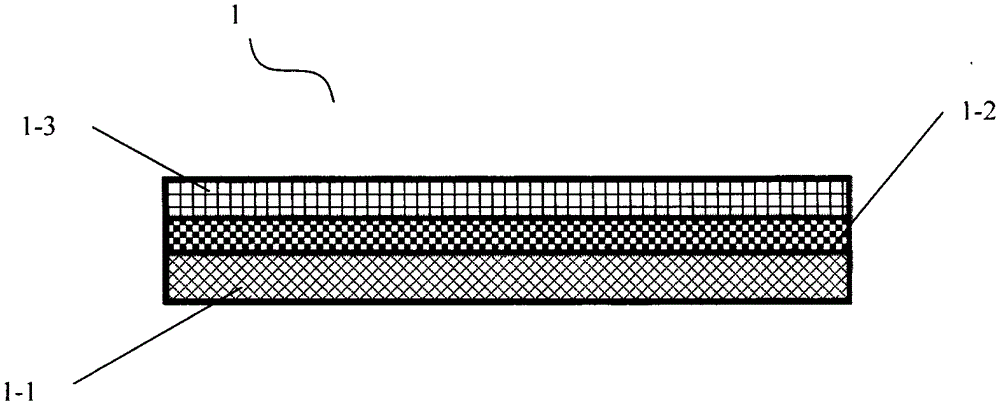

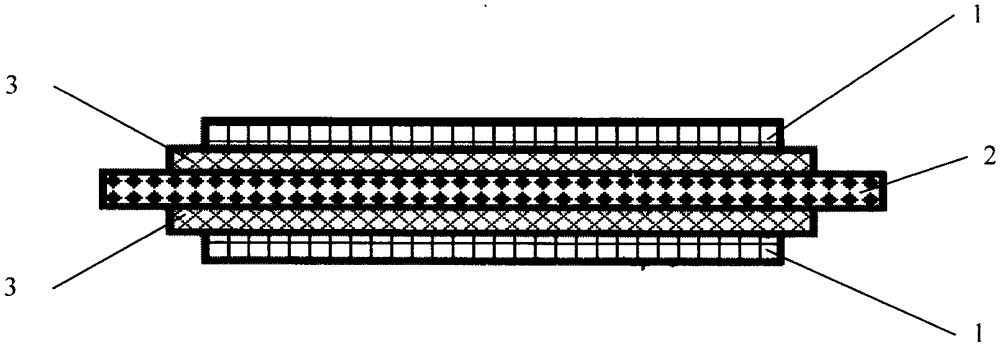

[0025] Such as figure 1 As shown, lithium cobalt oxide, conductive agent, and binder are mixed and slurried by known technology, coated on an aluminum foil current collector, dried, and cut into sheets to obtain a positive plate; artificial graphite, conductive agent, and adhesive The positive electrode plate is obtained by cutting the positive plate after being pressed into sheets; the metal strip-shaped electrode terminals 2 with rough surfaces are respectively welded on the positive and negative plate; the positive plate is separated by a separator Separated from the negative plate and wound to form a battery core; the battery core is placed in a packaging film 1 composed of a nylon film layer / SiOx-PET evaporated film layer / PP film layer, and wrapped; as figure 2 As shown, a piece of acid-modified PP polymer resin layer 3 is placed on the upper and lower sides of the electrode terminal 2 heat-sealed by the packaging film 1, and then the packaging film 1, electrode terminal...

Embodiment 2

[0027] Basically the same as Example 1, the difference is: replace lithium cobaltate with lithium nickelate; replace nylon film layer / SiOx-PET with PET film layer / montmorillonite-PP coated film layer / PP film layer composite packaging film 1 Packaging film 1 composed of evaporated film layer / PP film layer; mesophase carbon fiber balls are used instead of artificial graphite; acid-modified PP is used instead of acid-modified PE; lithium tetrafluoroborate, propylene carbonate, SEI film-forming additives, anti Gel electrolytes made of overcharge additives, electrolyte stabilizers, conductivity-enhancing additives, and antioxidant additives replace liquid electrolytes made of lithium hexafluorophosphate, ethylene carbonate, anti-overcharge additives, and flame-retardant additives.

Embodiment 3

[0029] Basically the same as Example 1, the difference is: replace lithium cobaltate with lithium manganese phosphate-lithium vanadium phosphate; replace the nylon film layer with packaging film 1 composed of PP-PE film layer / MgOx-PVC vapor-deposited film layer / PE film layer / SiOx-PET evaporation film layer / PP film layer composite packaging film 1; use soft carbon-lithium titanate instead of artificial graphite; use lithium perchlorate, ethyl acetate, anti-overcharge additives, electrolyte stabilizers, anti-oxidation The liquid electrolyte made of additives replaces the liquid electrolyte made of lithium hexafluorophosphate, ethylene carbonate, anti-overcharge additives, and flame retardant additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com