A kind of low-temperature aluminum soldering solder paste and preparation method thereof

A technology of aluminum solder and solder paste, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as weak solder joints, reduced solder joint life, sticky solder paste, etc., to achieve good printing performance and anti-collapse Excellent performance, good resistance to electrochemical corrosion, full and bright solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

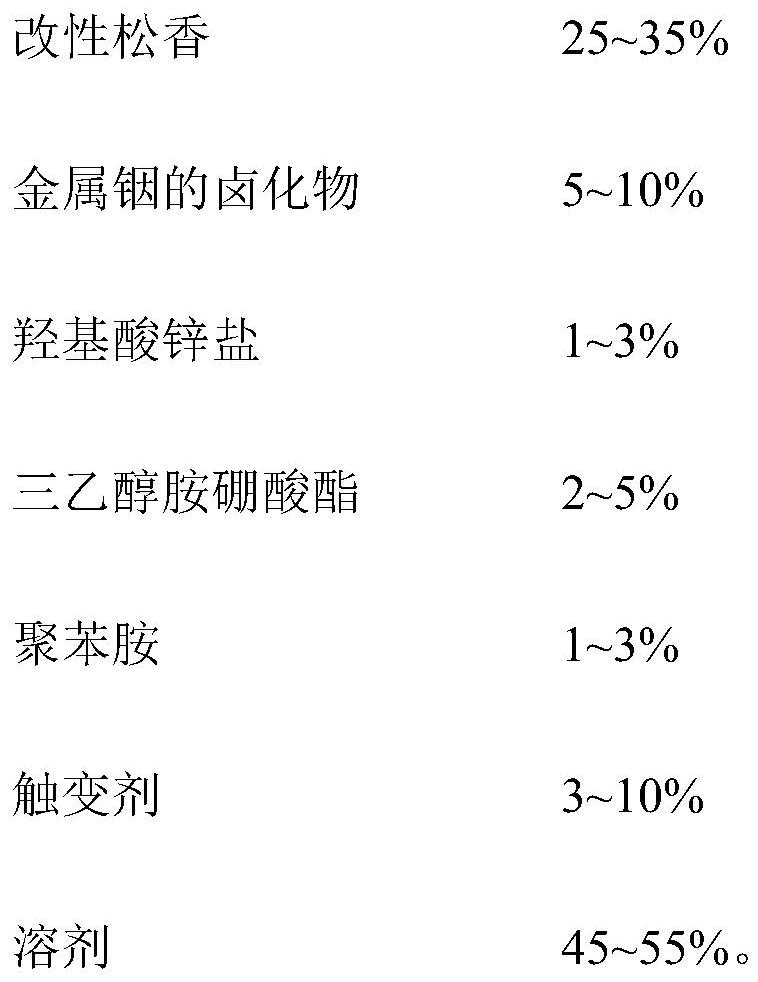

[0027] A low-temperature aluminum soldering solder paste, which consists of the following components by mass percentage: 85% of Sn64Bi35Ag1 alloy powder and 15% of flux, and the flux includes the following components by mass percentage: 30% of fully hydrogenated rosin , Indium Fluoride 10%, Zinc Tartrate 2%, Triethanolamine Borate 4%, Polyaniline 2%, Hydrogenated Castor Oil 7%, and Solvent 45%.

[0028] Preparation steps:

[0029] (1) Add fully hydrogenated rosin and ethylene glycol monobutyl ether into the reaction kettle, stir fully at 100°C, cool to 70°C after the fully hydrogenated rosin is completely melted, add triethanolamine borate, polyaniline, hydrogenated Castor oil, continue to stir until the material dissolves, after cooling to 40°C, add indium fluoride and zinc tartrate, stir evenly, and obtain flux;

[0030] (2) Refrigerate the flux at 2°C for 12 hours, return to temperature at room temperature, grind it with a three-roll mill until the particle size of the flu...

Embodiment 2

[0032] A low-temperature aluminum soldering solder paste is composed of the following components by mass percentage: 90% of Sn3Ag0.5Cu96.5 alloy powder and 10% of flux, and the flux includes the following components by mass percentage: Rosin 25%, indium chloride 5%, zinc citrate 3%, triethanolamine borate 5%, polyaniline 3%, ethylene bis-stearamide 10%, and diethylene glycol butyl ether 49%.

[0033] Preparation steps:

[0034] (1) Add polymerized rosin and diethylene glycol butyl ether into the reaction kettle, stir fully at 120°C, cool to 80°C after the polymerized rosin is completely melted, add triethanolamine borate, polyaniline, ethylene glycol Distearic acid amide, continue to stir until the material dissolves, after cooling to 50°C, add indium chloride and zinc citrate, stir evenly, and obtain flux;

[0035] (2) Refrigerate the flux at 10°C for 24 hours, return to normal temperature, and grind it with a three-roll mill until the particle size of the flux is 10-20 μm, ...

Embodiment 3

[0037]A low-temperature aluminum soldering solder paste, which consists of the following components by mass percentage: 80% of Sn58Bi42 alloy powder and 20% of flux, and the flux includes the following components by mass percentage: 30% of disproportionated rosin, Indium Bromide 8%, Zinc Salicylate 1%, Triethanolamine Borate 2%, Polyaniline 2%, Polyamide Modified Hydrogenated Castor Oil 7%, and Dipropylene Glycol Dimethyl Ether 50%.

[0038] Refer to Example 1 for the preparation steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com