Preparation method of nano Fe3O4/CeO2 composite material and application thereof

A composite material, fe3o4 technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, increase of COD, and large amount of reagents, etc., to achieve no The effect of secondary pollution, low equipment requirements, and thorough secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Nano-CeO by Liquid Phase Precipitation 2 Particles, the steps are as follows: the concentration of 0.1mol / L (NH 4 ) 2 CO 3 ·H 2 O was quickly added as a precipitant to Ce(NO 3 ) 3 ·6H 2 O solution, (NH 4 ) 2 CO 3 ·H 2 O solution and Ce(NO 3 ) 3 ·6H 2 The volume ratio of the O solution is 3:2, and the surfactant polyethylene glycol 4000 (PEG 4000) of 4g / L is added at the same time, the reaction time is 10min, the reaction temperature is 40°C, stirring, and the reaction generates a precursor; the precursor sol After filtering, wash twice with deionized water to remove impurities, put the filtered precursor into a beaker filled with absolute ethanol, and disperse it with ultrasonic waves for 10 minutes; then filter, vacuum dry, and then bake in air at 300 °C 1h, get nano-CeO 2 particles.

[0030] Then nano-CeO 2 The particles are used as the carrier, and the Massart hydrolysis method in the co-precipitation method is used to prepare nano-Fe ...

Embodiment 2

[0037] Preparation of Nano-CeO by Liquid Phase Precipitation 2 Particles, the steps are as follows: the concentration of 0.1mol / L (NH 4 ) 2 CO 3 ·H 2 O was quickly added as a precipitant to Ce(NO at a concentration of 0.2mol / L 3 ) 3 ·6H 2 O solution, (NH 4 ) 2 CO 3 ·H 2 O solution and Ce(NO 3 ) 3 ·6H 2The volume ratio of the O solution is 3:1, and 4g / L surfactant polyethylene glycol 4000 (PEG 4000) is added at the same time, the reaction time is 20min, the reaction temperature is 60°C, stirring, and the reaction generates a precursor; the precursor sol After filtering, wash twice with deionized water to remove impurities, put the filtered precursor into a beaker filled with absolute ethanol, and disperse it with ultrasonic waves for 10 minutes; then filter, vacuum dry, and then bake in air at 300 °C 1h, get nano-CeO 2 particles.

[0038] Then nano-CeO 2 The particles are used as the carrier, and the Massart hydrolysis method in the co-precipitation method is us...

Embodiment 3

[0045] Nano Fe 3 o 4 / CeO 2 The preparation process of the composite material is the same as in Example 1.

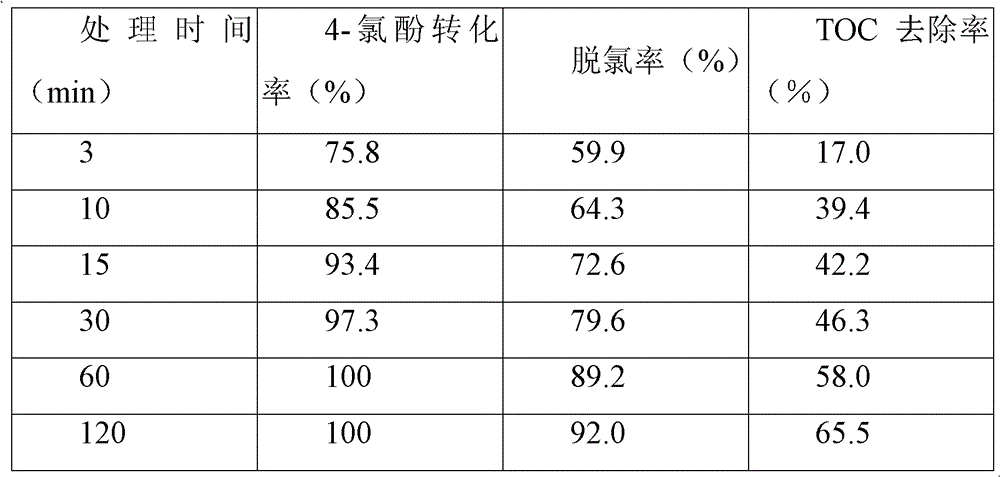

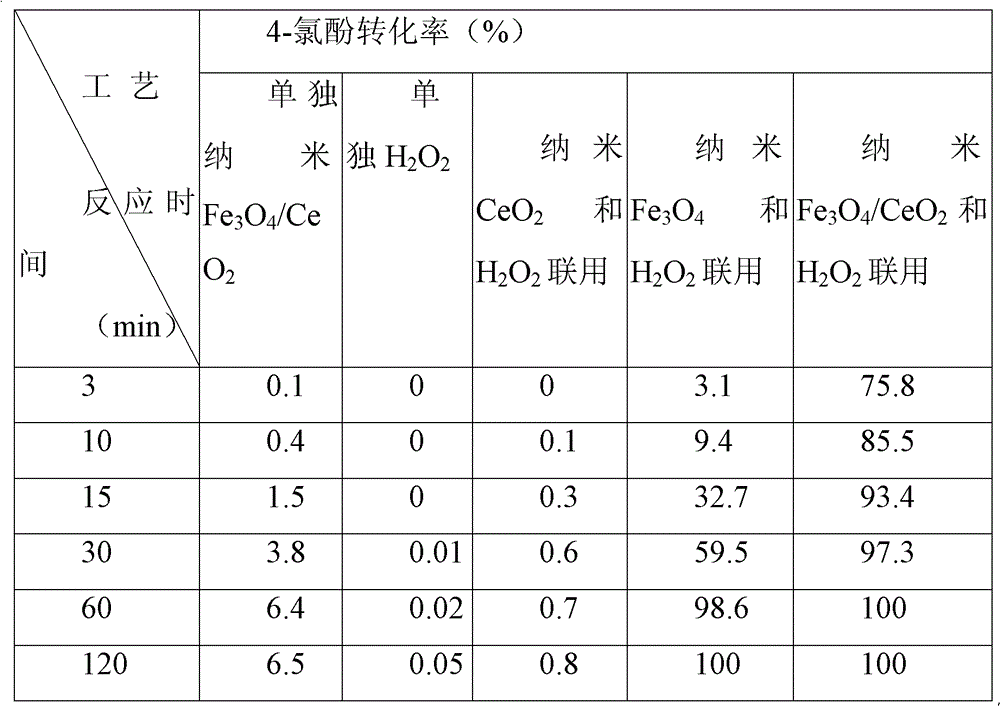

[0046] Experiments compared the addition of nano-Fe alone 3 o 4 / CeO 2 , add H alone 2 o 2 , Nano CeO 2 and H 2 o 2 Combined use, nano-Fe 3 o 4 and H 2 o 2 Combined use, nano-Fe 3 o 4 / CeO 2 and H 2 o 2 The difference in the removal rate of 4-chlorophenol under the combination of five processes.

[0047] Add nano-Fe separately 3 o 4 / CeO 2 In the experiment, the Erlenmeyer flask was used as the reactor, and the treatment conditions were 4-chlorophenol-containing wastewater with a concentration of 100mg / L, pH 3.0, and the addition of 2.0g / L nano-Fe 3 o 4 / CeO 2 , the reactor was placed in a water bath shaker with a rotation speed of 150 rpm and a temperature of 30 °C.

[0048] Add H alone 2 o 2 In the experiment, 30mM H was added to the reactor 2 o 2 , and the other conditions are the same as above.

[0049] nano-CeO 2 and H 2 o 2 In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com