Component for light-emitting device, light-emitting device and producing method thereof

A technology for light-emitting devices and parts, which is applied to parts of lighting devices, cooling/heating devices of lighting devices, electroluminescent light sources, etc. Manufacturing cost and effect of ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] (1) Synthesis of phosphors (raw material particles) (synthesis of YAG:Ce phosphors)

[0117] 0.14985 mol (14.349 g) of yttrium nitrate hexahydrate, 0.25 mol (23.45 g) of aluminum nitrate hexahydrate, and 0.00015 mol (0.016 g) of cerium nitrate hexahydrate were dissolved in 250 mL of distilled water to prepare a 0.4 M precursor ( precursor) solution.

[0118] The precursor solution was sprayed onto a high-frequency (RF) induced plasma flame at a rate of 10 mL / min using a two-fluid nozzle, and thermally decomposed to obtain inorganic powder particles (raw material particles).

[0119] The obtained raw material particles were analyzed by X-ray diffraction method, showing that the amorphous phase and YAP (YAlO 3 ) mixed phase of crystallization.

[0120]In addition, the average particle diameter determined by the specific surface area analysis (BET: Brunauer-Emmett-Teller) method using an automatic surface area measuring device (manufactured by Micrometritics, model Gemin...

Embodiment 2

[0143] In the process of "(3) Preparation of Ceramic Green Tape Laminates of Aluminum Oxide", except that alumina particles are not used but YAG:Ce particles (that is, ceramic green tape laminates for manufacturing YAG) are used, the same as in Example 1 A light-emitting device was produced in the same manner.

Embodiment 3

[0145] A ceramic green tape laminate of YAG was produced in the same manner as in "(2) Preparation of a ceramic green tape laminate of YAG" in Example 1, and a fluorescent layer (fluorescence body board). In addition, no ceramic green tape laminate of alumina was produced.

[0146] In addition, barium titanate particles (manufactured by Sakai Chemical Industry Co., Ltd., product number BT-03) as scattering particles were dispersed in the two liquids at a ratio of 40% by weight using an applicator. The solution obtained after mixing thermosetting silicone elastomer (manufactured by Shin-Etsu Silicone Co., Ltd., product number KER2500) is applied on a PET film with a thickness of about 500 μm, heated at 100°C for 1 hour, and then heated at 150°C for 1 hour, Thus, a reflective resin sheet is produced.

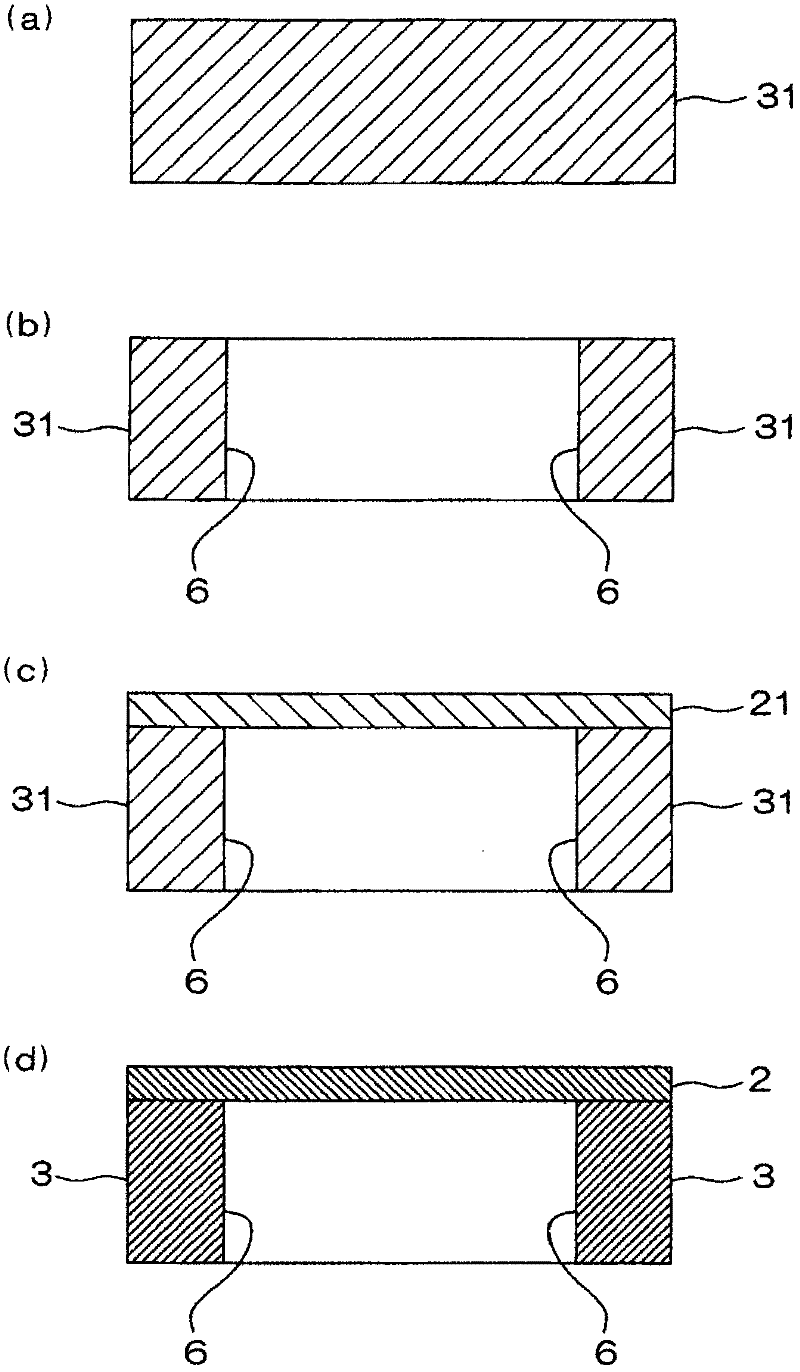

[0147] This resin sheet was formed into an outer dimension of 3.2 mm x 3.2 mm and an inner diameter of 1.6 mm x 1.6 mm using a laser cutting device. The thus-formed reflective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com