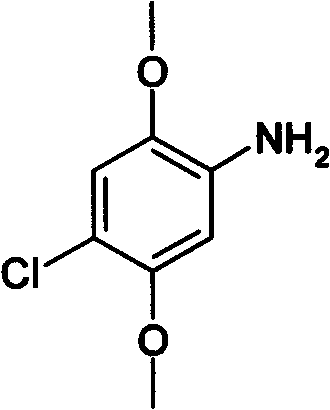

Method for preparing 2,5-dimethoxy-4-chloroaniline by using liquid-phase catalytic hydrogenation method

A technology of dimethoxyl and liquid phase catalysis, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc. It can solve the problems of unfriendly environment, achieve low reaction energy consumption, inhibit dechlorination, The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

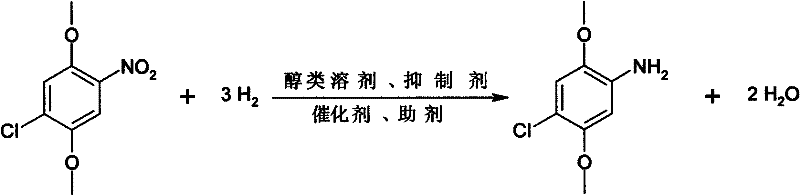

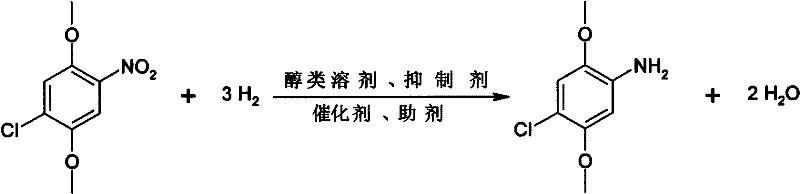

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing 2,5-dimethoxy-4-chloroaniline by liquid-phase catalytic hydrogenation method, comprising:

[0025] (a). Add 50 g of 2,5-dimethoxy-4-chloronitrobenzene, 400 g of ethanol, 1.5 g of Raney nickel, and 0.5 g of dimethyl sulfoxide in a high-pressure reactor with a stirring temperature measuring device , dicyandiamide 1g and close the kettle lid. Use N2 to detect leaks and replace the air several times, then add hydrogen to replace to pass, at the same time increase the pressure to 0.7Mpa, raise the temperature to 70°C, and continuously feed hydrogen to maintain the hydrogen pressure at 0.7Mpa. After maintaining the temperature and pressure for 2 hours, the hydrogen pressure did not drop, and the reaction was terminated.

[0026] (b). After filtering the reaction solution to remove the catalyst, add 1.5g of activated carbon and 0.5g of protective agent to the reaction solution, heat up to 85°C, keep the temperature and reflux for 20 minutes and then fil...

Embodiment 2

[0029] A method for preparing 2,5-dimethoxy-4-chloroaniline by liquid-phase catalytic hydrogenation method, comprising:

[0030] (a). Add 2,5-dimethoxy-4-chloronitrobenzene 50g, methanol 600g, Raney nickel 2g, dimethyl sulfoxide 1g, bis 1.5g of cyanamide Close the lid of the kettle, use N2 to detect leaks and replace the air several times, then add hydrogen to replace to pass, at the same time pressurize to 0.6Mpa, heat up to 60°C, continuously feed hydrogen to maintain the hydrogen pressure at 0.6Mpa. After maintaining the temperature and pressure for 3 hours, the hydrogen pressure did not drop any more, and the reaction was terminated.

[0031] (b). After filtering the reaction solution to remove the catalyst, add 2g of activated carbon and 0.5g of protective agent to the reaction solution, raise the temperature to 85°C, keep the temperature and reflux for 20 minutes, then filter while it is hot, discard the activated carbon, and cool the filtrate to 20 ℃ to make it fully c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com