Thickener and preparation method thereof

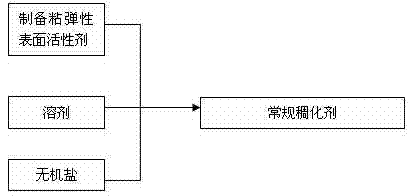

A thickener and long-chain technology, which is applied in the field of thickeners for the preparation of clean and viscous acids, can solve the problem of acidification reformation of marine carbonate reservoirs, deep burial and thickening of marine carbonate reservoirs. Solve the problems of low temperature resistance of the agent, and achieve the effect of strong practicability, good performance and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0049] Example 1-5 (See Table 1)

[0050] Table 1 is five groups of formulas (raw material components and content) of the present invention in the following table

[0051]

[0052] The sodium salt in the above table is a by-product obtained during the reaction of long-chain fatty acid amidopropyl betaine. It does not need to be purchased and added separately, which makes rational use of resources and helps reduce production costs.

Embodiment 6

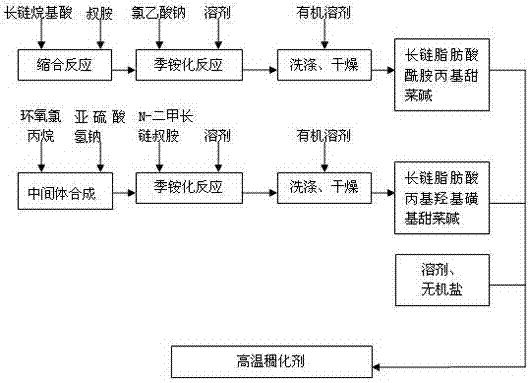

[0054] see image 3 , the preparation method of the present invention comprises the following sequential steps:

[0055] A. prepare long-chain fatty acid propyl hydroxy sultaine and long-chain fatty acid amidopropyl betaine respectively;

[0056] Wherein, the preparation of long-chain fatty acid propyl hydroxy sultaine comprises the following specific steps, a. under the condition that the pH value is 6, epichlorohydrin and sodium bisulfite are dripped in with the ratio of 1:1.2, Keep it at 1.5h to finish dropping, stir after dropping, control the reaction temperature to 88°C, and the reaction time to 4h to synthesize the intermediate product; b. The mass ratio of N,N-dimethyl long-chain tertiary amine to the intermediate product is 1: Put in N,N-dimethyl long-chain tertiary amine at a ratio of 1.05, the carbon chain number of N,N-dimethyl long-chain tertiary amine is 18, use a little phenolphthalein indicator as a solvent indicator, add a basic catalyst dropwise to keep the ...

Embodiment 7

[0069] see image 3 , the preparation method of the present invention comprises the following sequential steps:

[0070] A. prepare long-chain fatty acid propyl hydroxy sultaine and long-chain fatty acid amidopropyl betaine respectively;

[0071] Wherein, the preparation of long-chain fatty acid propyl hydroxy sultaine comprises the following specific steps, a. under the condition of pH 6.2, epichlorohydrin and sodium bisulfite are dripped with the ratio of 1:1.2, keeping After 1.5 hours of dropping, stir after dropping, control the reaction temperature at 85°C, and the reaction time of 4 hours to synthesize an intermediate product; b. The mass ratio of N,N-dimethyl long-chain tertiary amine to intermediate product is 1:1.05 Add N,N-dimethyl long-chain tertiary amine, the carbon chain number of N,N-dimethyl long-chain tertiary amine is 20, use a little phenolphthalein indicator as solvent indicator, add alkaline catalyst dropwise to keep the system alkaline , carry out the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com