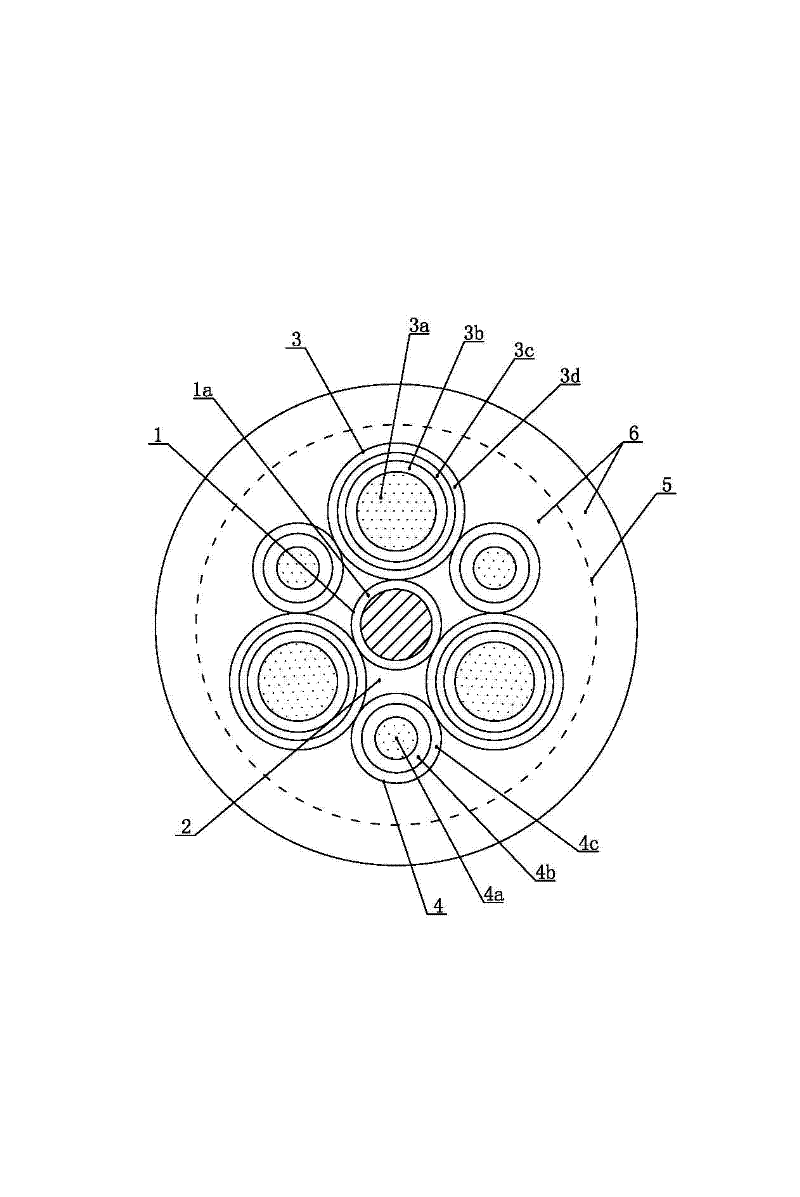

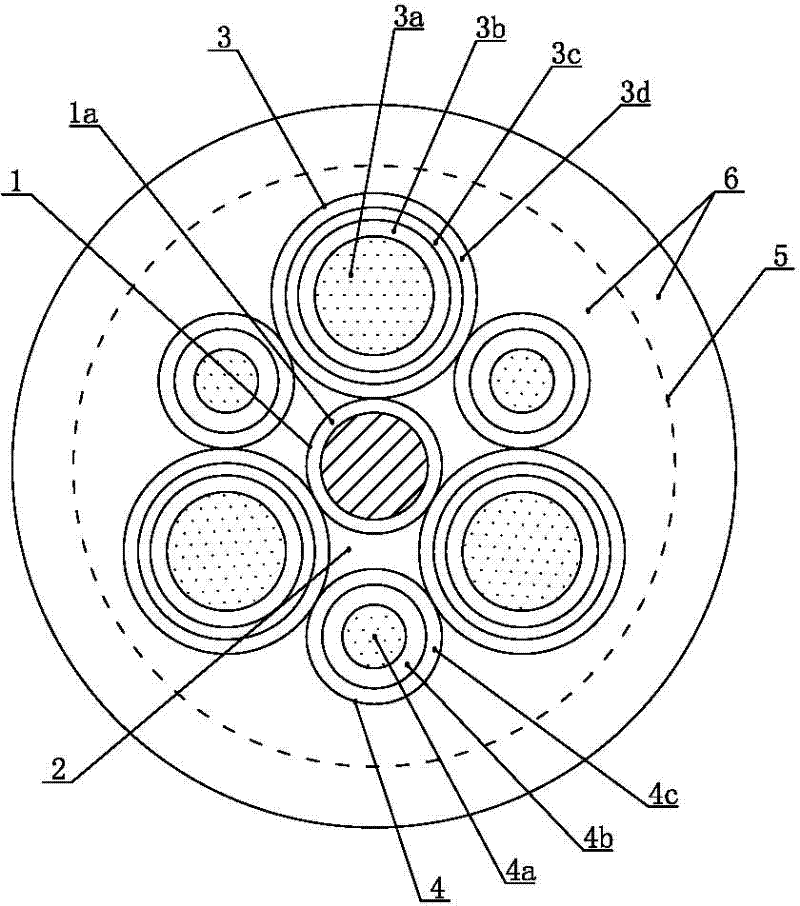

Power cable for underwater shovel arm of dredger and manufacturing method thereof

A technology for power cables and dredgers, which is applied in the field of manufacturing power cables for underwater shovel arms of dredgers and power cables for underwater shovel arms of dredgers. It can solve the problems that the cable core cannot undergo large deformation, etc. Achieve the effects of avoiding run-on deformation, reducing tension, and avoiding partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare raw materials according to the following components and weight content: ethylene propylene rubber 2470B: 10.5 parts; ethylene propylene rubber 378K: 7.5 parts; dibenzothiazole disulfide DM: 0.1 parts; zinc oxide: 2.0 parts; Imidazole MB: 0.4 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer RD: 0.3 parts; titanium dioxide: 0.7 parts; microcrystalline paraffin: 1.5 parts; aluminum hydroxide: 1.5 parts ; Stearic acid: 0.2 parts; White carbon black: 1.5 parts; Superfine talcum powder: 12 parts; Calcined clay: 0.2 parts; Dicumyl peroxide DCP: 0.5 parts;

[0024] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470B and ethylene-propylene rubber 378K on an internal mixer; then add antioxidant MB (2-mercaptobenzimidazole) and resinous antioxidant RD ( 2,2,4-trimethyl-1,2-dihydroquinoline polymer), plasticizer microcrystalline paraffin, active agent zinc oxide, flame retardant aluminum hydroxide, filler superfine talcum p...

Embodiment 2

[0026] Prepare raw materials according to the following components and weight content: ethylene propylene rubber 2470B: 10.5 parts; ethylene propylene rubber 378K: 7.5 parts; dibenzothiazole disulfide DM: 0.2 parts; zinc oxide: 2.2 parts; Imidazole MB: 0.5 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer RD: 0.4 parts; titanium dioxide: 1.0 parts; microcrystalline paraffin: 1.8 parts; aluminum hydroxide: 1.8 parts ; Stearic acid: 0.3 parts; White carbon black: 2.0 parts; Superfine talcum powder: 14 parts; Calcined clay: 0.3 parts; Dicumyl peroxide DCP: 0.7 parts;

[0027] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470B and ethylene-propylene rubber 378K on an internal mixer; then add antioxidant MB (2-mercaptobenzimidazole) and resinous antioxidant RD ( 2,2,4-trimethyl-1,2-dihydroquinoline polymer), plasticizer microcrystalline paraffin, active agent zinc oxide, flame retardant aluminum hydroxide, filler superfine talcum p...

Embodiment 3

[0029] Prepare raw materials according to the following components and weight content: ethylene propylene rubber 2470B: 10.5 parts; ethylene propylene rubber 378K: 7.5 parts; dibenzothiazole disulfide DM: 0.3 parts; zinc oxide: 2.5 parts; Imidazole MB: 0.6 parts; 2,2,4-trimethyl-1,2-dihydroquinoline polymer RD: 0.5 parts; titanium dioxide: 1.5 parts; microcrystalline paraffin: 2.0 parts; aluminum hydroxide: 2 parts ; Stearic acid: 0.5 parts; White carbon black: 2.5 parts; Superfine talcum powder: 16 parts; Calcined clay: 0.4 parts; Dicumyl peroxide DCP: 1.0 parts;

[0030] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470B and ethylene-propylene rubber 378K on an internal mixer; then add antioxidant MB (2-mercaptobenzimidazole) and resinous antioxidant RD ( 2,2,4-trimethyl-1,2-dihydroquinoline polymer), plasticizer microcrystalline paraffin, active agent zinc oxide, flame retardant aluminum hydroxide, filler superfine talcum pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com