Preparation method and application of enzymolysis lactoalbumin/xanthan gum composite gel

A whey protein and composite gel technology, which is used in the preparation of low-fat cheese, enzymatic hydrolyzed whey protein/xanthan gum composite gel, low-fat yogurt and low-fat ice cream, and can solve the problem of large equipment consumption. , high shear force, high equipment configuration requirements, etc., to achieve the effect of good substitution effect, simple and easy operation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

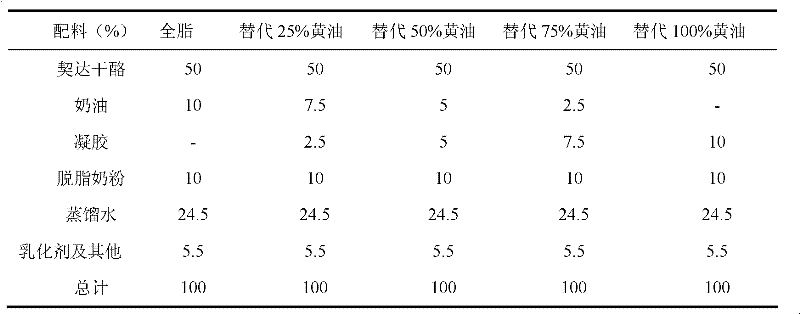

Embodiment 1

[0025] (1) Whey protein solids, xanthan gum and calcium chloride are respectively made into solutions, and the three are mixed to form a whey protein mass concentration of 20%, a xanthan gum mass concentration of 0.05%, and a calcium chloride concentration of 2g / L mixed solution, stirred at room temperature for 20min, the speed is 300r / min;

[0026] (2) Adjust the pH value of the mixed solution obtained in step (1) to 7.0, stir and heat at 80° C. for 20 min at a stirring speed of 200 r / min, and cool at room temperature.

[0027] The whey protein / xanthan gum composite gel prepared by this method has a hardness of 2.84N, a cohesiveness of 0.41, an adhesiveness of 0.85N.sec, an average particle size of 630μm, and a hardness value exceeding the standard cream texture value There are many ranges, the average particle size is more than 30 times that of standard cream, and the surface is rough, which does not have the characteristics of simulating fat.

Embodiment 2

[0029] (1) Whey protein solids, xanthan gum and calcium chloride are respectively made into solutions, and the three are mixed to form a whey protein mass concentration of 17%, a xanthan gum mass concentration of 0.3%, and a calcium chloride concentration of 3g / L mixed solution, stirred at room temperature for 20min, the speed is 300r / min;

[0030] (2) Adjust the pH value of the mixed solution obtained in step (1) to 7.0, stir and heat at 80° C. for 25 min at a stirring speed of 200 r / min, and cool at room temperature.

[0031] The hardness of the whey protein / xanthan gum composite gel obtained by this method is 1.84N, the cohesion is 0.21, the adhesion is 0.75N.sec, the average particle size is 530μm, and the hardness value exceeds the range of the standard cream hardness value by a lot. The average particle size is more than 25 times that of the standard cream particle size, and the surface is rough, which does not have the characteristics of imitating fat.

[0032] From Ex...

Embodiment 3

[0034] (1) Prepare a whey protein solution with a substrate mass concentration of 20%, and stir at 250r / min for 30min at room temperature to fully hydrate it;

[0035] (2) Adjust the pH value of the whey protein solution obtained in step (1) to 7.0, add alkaline protease, the mass ratio of the added alkaline protease to whey protein solution is 1:10, and enzymolyze at 50°C 50min, the degree of hydrolysis is 6.5%;

[0036] (3) Inactivate the enzymatic whey protein solution obtained in step (2) in a water bath at 70°C for 10 minutes, freeze it in a refrigerator at -20 to -80°C after rapid cooling, and freeze-dry to obtain an enzymatic whey protein powder;

[0037] (4) The enzymolyzed whey protein powder, xanthan gum and calcium chloride obtained in step (3) are made into solutions respectively, and the three are mixed to form a whey protein mass concentration of 20%, and a xanthan gum mass concentration of 0.05 %, a mixed solution with a calcium chloride concentration of 2g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com