Enzyme imitation type water treatment agent for degrading polycycic/heterocyclic aromatic hydrocarbon, and preparation method for enzyme imitation type water treatment agent

The technology of a water treatment agent and heterocyclic aromatic hydrocarbons is applied in the field of imitative enzyme type water treatment agent and its preparation, and achieves the effects of reducing loss, improving removal efficiency and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An enzyme-like water treatment agent for degrading poly / heterocyclic aromatic hydrocarbons and a preparation method thereof. The steps of its preparation method are as follows:

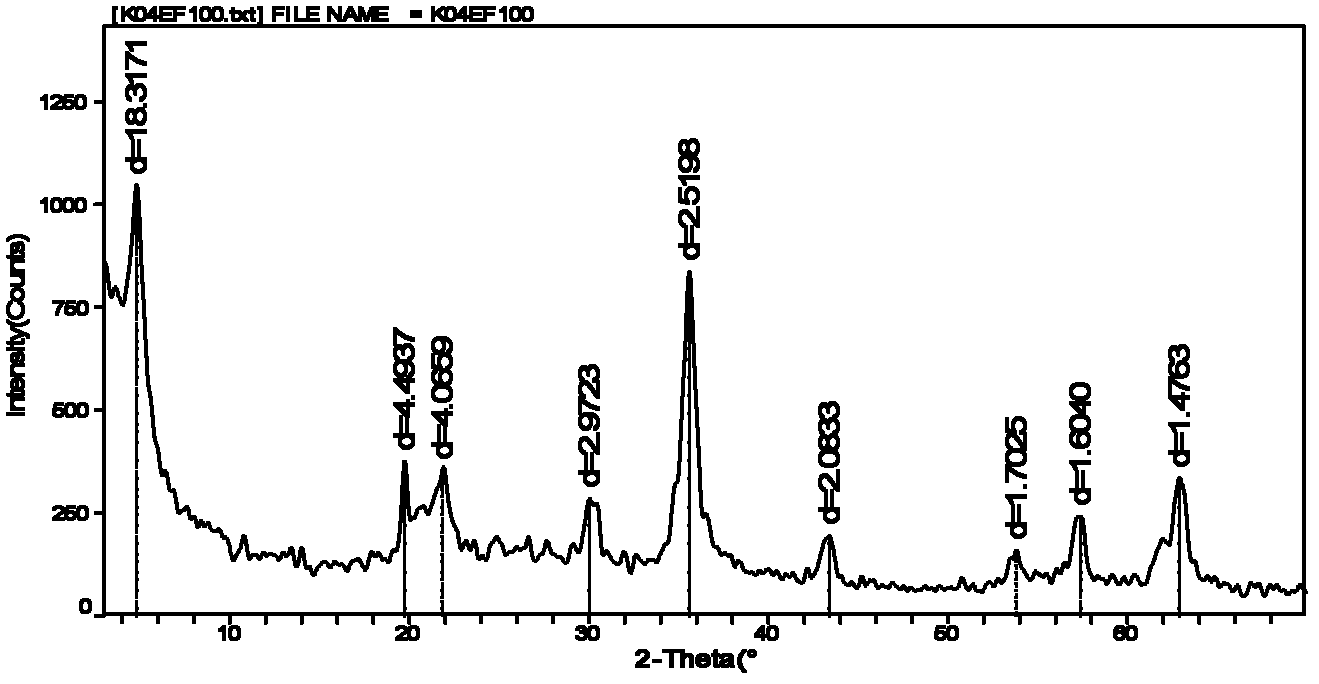

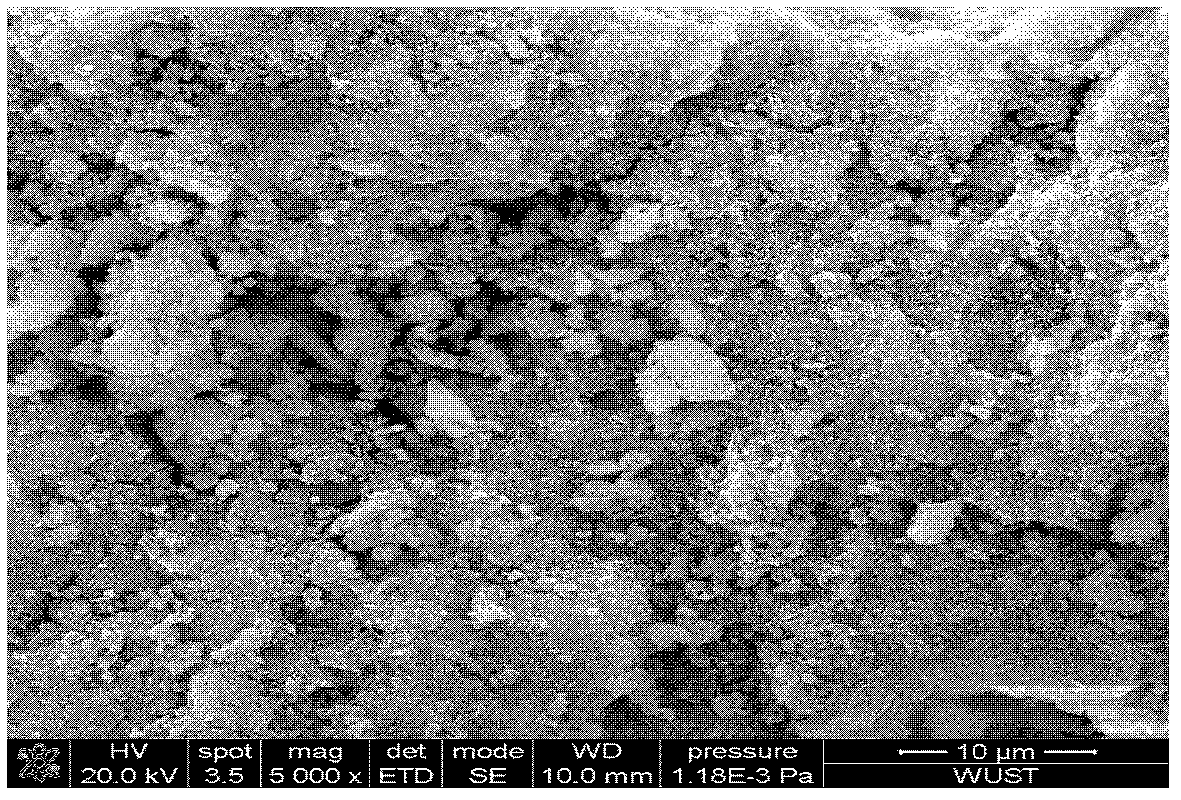

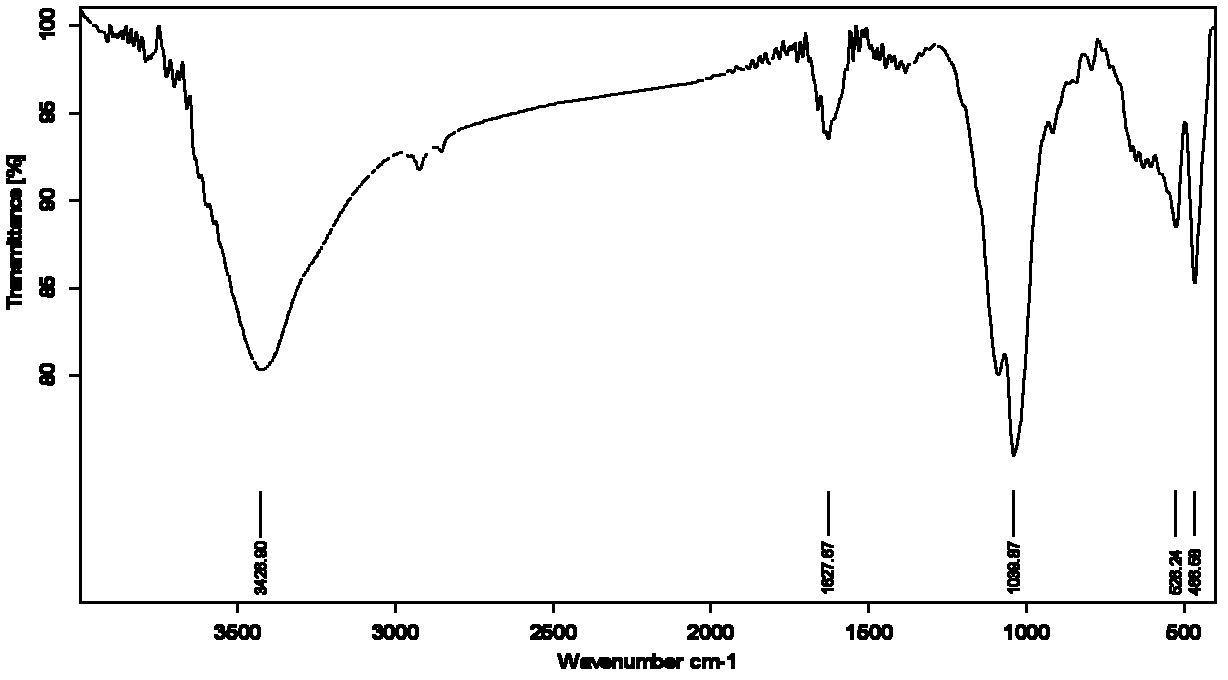

[0028] Step 1. Mix bentonite: deionized water according to the mass ratio of 1: (30-40), put it in the reaction kettle, stir for 20-40min under the conditions of 20-30°C and 60-150r / min, and let it stand After 8-12 hours, remove the upper layer, take the middle layer, then dry at 70-90°C for 5-6 hours, and crush to obtain purified bentonite.

[0029] Step 2. Mix the purified bentonite: sodium chloride solution evenly in a mass ratio of 1: (1-1.5), place it in another reaction kettle, and put it in a constant temperature water bath at 70-90°C and under the condition of 60-150r / min Stir for 30-60 minutes; then conduct liquid-solid separation to obtain a solid, wash the solid with deionized water until there is no chloride ion; then dry and grind at 100-120°C, and pass through a 200-mesh sieve to...

Embodiment 2

[0039] An enzyme-like water treatment agent for degrading poly / heterocyclic aromatic hydrocarbons and a preparation method thereof. The steps of its preparation method are as follows:

[0040] Step 1. Mix bentonite: deionized water according to the mass ratio of 1: (40-50), put it in the reaction kettle, stir for 20-40min under the conditions of 20-30°C and 60-150r / min, and let it stand After 8-12 hours, remove the upper layer, take the middle layer, then dry at 70-90°C for 5-6 hours, and crush to obtain purified bentonite.

[0041] Step 2. Mix the purified bentonite: sodium chloride solution evenly in a mass ratio of 1: (1.5-2.0), place it in another reaction kettle, and put it in a constant temperature water bath at 70-90°C and under the condition of 60-150r / min Stir for 30-60 minutes; then conduct liquid-solid separation to obtain a solid, wash the solid with deionized water until there is no chloride ion; then dry and grind at 100-120°C, and pass through a 200-mesh sieve ...

Embodiment 3

[0052] An enzyme-like water treatment agent for degrading poly / heterocyclic aromatic hydrocarbons and a preparation method thereof. The steps of its preparation method are as follows: step 1, mix bentonite: deionized water in a mass ratio of 1: (50-60), place it in a reaction kettle, and heat it under the conditions of 20-30°C and 60-150r / min Stir for 20-40 minutes, stand still for 8-12 hours, remove the upper layer, take the middle layer, then dry at 70-90 °C for 5-6 hours, and crush to obtain purified bentonite.

[0053] Step 2. Mix the purified bentonite: sodium chloride solution evenly in a mass ratio of 1: (2.0-2.5), place it in another reaction kettle, and put it in a constant temperature water bath at 70-90°C and under the condition of 60-150r / min Stir for 30-60 minutes; then conduct liquid-solid separation to obtain a solid, wash the solid with deionized water until there is no chloride ion; then dry and grind at 100-120°C, and pass through a 200-mesh sieve to obtain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com