Extraction, purification and preparation method of high-purity salvianolic acid B

A purification method and technology of salvianolic acid, which are applied in the field of preparation of high-purity salvianolic acid B extraction and separation, can solve the problems of reduced extraction rate of salvianolic acid B, increased impurities, and less sample amount, and achieve improved dissolution rate and Extraction efficiency, simple extraction method, less damage or loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

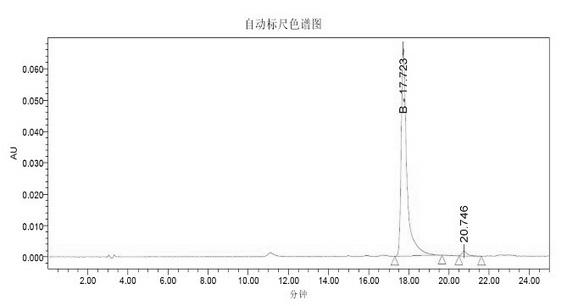

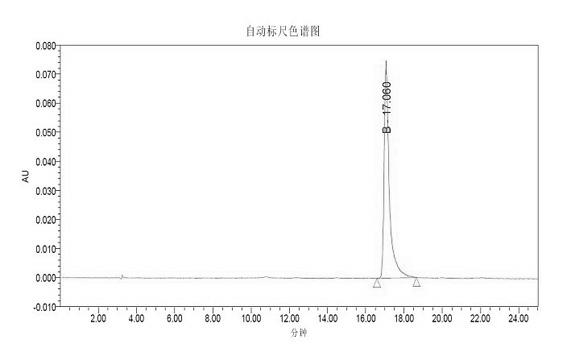

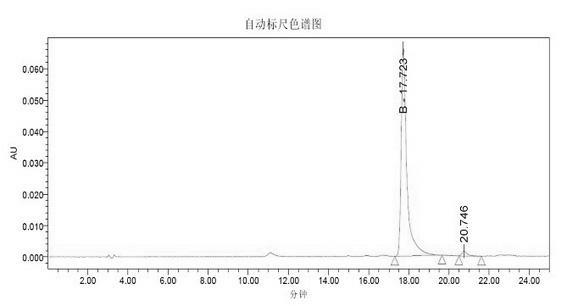

Image

Examples

Embodiment 1

[0035]1. Extraction: take 500g of Danshen medicinal material crushed into fine powder, add 10 times the volume (V / W) of 60% ethanol, soak at 5°C for 24 hours, and then ultrasonically extract for 30 minutes. During the extraction process, use circulating water to cool and control the temperature of the extract Centrifuge at no more than 20°C, and recover ethanol from the extract until it has no alcohol smell.

[0036] 2. Adsorption and separation of macroporous resin: the clarified non-alcoholic extract is placed on a D-101 macroporous resin column, and the ratio of the loaded sample (calculated based on the dry weight of the original medicinal material) to the amount of resin is 1:2 (W / V). Impurities were first eluted with 2 column volumes of water, and then 5 column volumes of 30% ethanol aqueous solution.

[0037] 3. Industrial chromatographic column chromatography: the eluted part of macroporous resin with 30% ethanol aqueous solution is concentrated to remove alcohol, and ...

Embodiment 2

[0040] Same as Example 1, the difference is that the medicinal material is added with 12 times the volume (V / W) of ethanol aqueous solution, and finally salvianolic acid B with a purity of 91.5% is obtained.

Embodiment 3

[0042] Same as Example 1, the difference is that the medicinal material is added with 15 times the volume (V / W) of the ethanol aqueous solution of the medicinal material, and finally salvianolic acid B with a purity of 92.5% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com