Dual-degradant additive for promoting photo oxidative degradation and biodegradation of polymer

A technology of biodegradation and photo-oxidation, applied in the field of dual-degradation additives, can solve the problems of incomparable petroleum-based materials, lack of degradation controllability, and impact on degradation effects, etc., to overcome the problem of low degradation efficiency, excellent physical and mechanical properties, Overcoming the effect of shorter degradation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

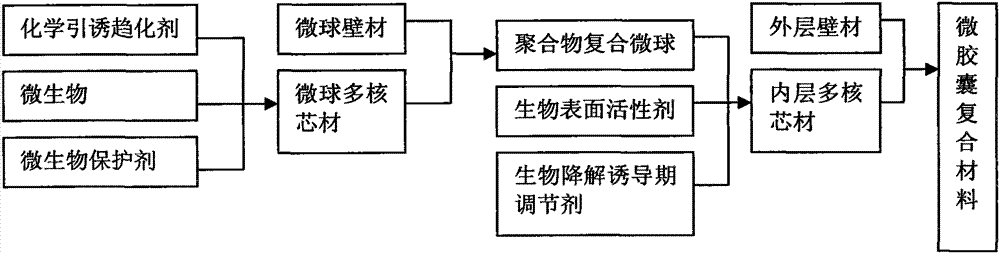

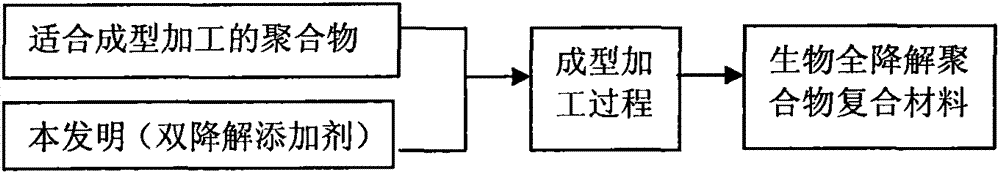

Method used

Image

Examples

Embodiment 1

[0176] The first stage: weigh the following substances according to their respective weight percentages, put them in a high-speed mixer, and mix them at a speed of 500 rpm for 30 minutes to make a mixture; then send the mixture into the Coperion (Nanjing) Machinery Co., Ltd.’s STS twin-screw extruder and granulation and cutting unit with an L / D of 32:1, the temperature at each extrusion end is 150°C, and the extruder speed is 600 rpm Under the condition of minute, carry out extruding granulation operation, make the present invention, promptly appearance is the double degradation additive of concentrated plastic masterbatch:

[0177] 1. Low-density polyethylene (LDPE) as carrier resin: 30%

[0178] 2. Composite photooxidative degradation accelerator: 40%

[0179] 3. Photooxidative degradation induction period regulator: 3%

[0180] 4.3-Phenylglutarate: 2%

[0181] 5. Microcapsule composite material: 25%

[0182] in:

[0183] A. The names and weight percentages of various c...

Embodiment 2

[0217] The following materials were mixed according to their respective weight percentages at a speed of 530 rpm for 40 minutes to make a mixture; then the mixture was sent to Coperion (Nanjing) Machinery Co., Ltd. where the length-to-diameter ratio L / D was 40:1. The company's STS twin-screw extruder and granulation and granulation unit perform extrusion and granulation operations under the conditions that the temperature of each extrusion end is 160 ° C and the speed of the extruder is 800 rpm to produce the present invention. , that is, the double-degradable additive with the appearance of concentrated plastic masterbatch:

[0218] 1. Ethylene vinyl acetate copolymer (EVA) as carrier resin: 35%

[0219] 2. Composite photooxidative degradation accelerator: 37%

[0220] 3. Photooxidative degradation induction period regulator: 3%

[0221] 4. Polylactic acid: 2%

[0222] 5. Microcapsule composite material: 23%

[0223] in:

[0224] A. The names and weight percentages of va...

Embodiment 3

[0259] The first stage: the following materials were mixed for 50 minutes at a speed of 820 rpm according to their respective weight percentages to make a mixture; then the mixture was sent to Coperion ( The STS twin-screw extruder and granulation and granulation unit of Nanjing) Machinery Co., Ltd. perform extrusion and granulation under the conditions that the temperature of each extrusion end is 170°C and the speed of the extruder is 800 rpm. The present invention is made, that is, the appearance is a dual-degradation additive of concentrated plastic masterbatch:

[0260] 1. Ethylene acrylic acid copolymer (EAA) as carrier resin: 38%

[0261] 2. Composite photooxidative degradation accelerator: 35%

[0262] 3. Photooxidative degradation induction period regulator: 2%

[0263] 4. Polycaprolactone: 2%

[0264] 5. Microcapsule composite material: 23%

[0265] in:

[0266] A. The names and weight percentages of various components in the composite photooxidative degradation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com