Preparation method for titanium oxynitride photocatalyst

A photocatalyst, titanium oxynitride technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems that have not been reported, and achieve the effect of simple preparation method and excellent hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

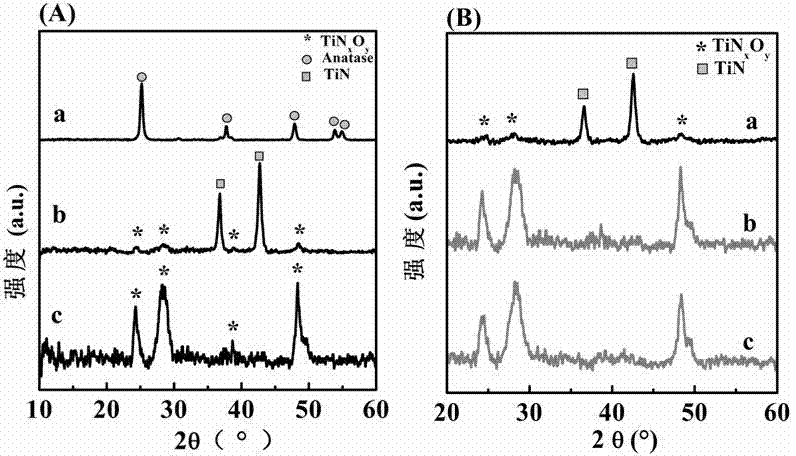

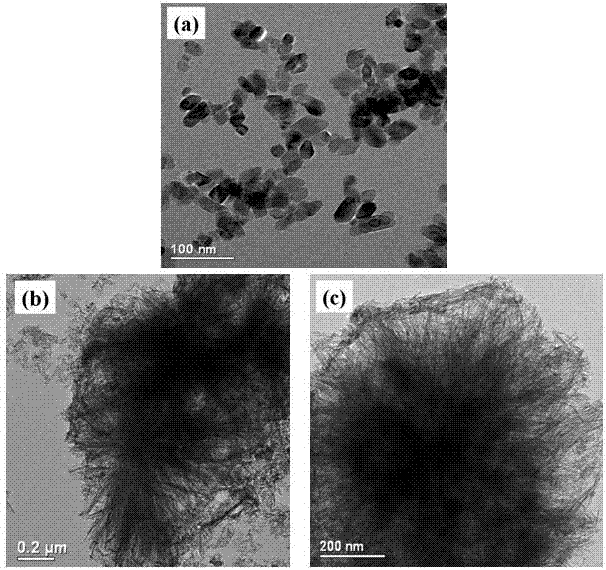

[0019] Example 1 : Disperse 0.2 g TiN powder in 30 mL 0.03 mol / L HF-0.1 mol / L H 2 o 2 In aqueous solution (TiN with oxidants HF and H 2 o 2 The molar ratios were 2.6 and 1.0), stirred evenly, and then transferred to a 100 mL hydrothermal kettle and kept in an oven at 180°C for 12 h. After cooling, the obtained samples were washed with deionized water until neutral, and dried to obtain a white Powder, XRD test shows that all TiN is transformed into anatase TiO 2 powder, such as figure 1 A(a); shows that in HF-H 2 o 2 TiN can be transformed into TiO in the system 2 . Scanning electron microscope results showed that the obtained powder was nanoparticles, such as figure 2 as shown in a.

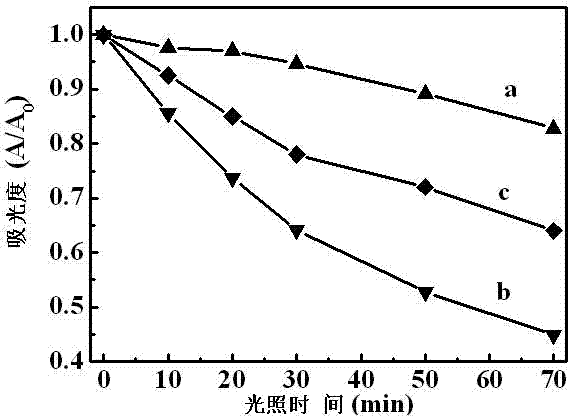

[0020] Adsorption performance test. Accurately weigh 5 mg of the prepared catalyst into a glass reactor, and add 40 mL of 5 mg / mL methylene blue solution. The system was placed in a dark state and stirred for 4 h under magnetic stirring to make it reach adsorption equilibrium. Th...

Embodiment 2

[0023] Example 2: Disperse 0.2 g TiN in 30 mL containing 0.03 mol / L HF and 0.1 mol / L H 2 o 2 5 mol / L sodium hydroxide aqueous solution (the molar ratio of TiN to concentrated alkali is 0.02, and the oxidants HF and H 2 o 2 The molar ratios were 2.6 and 1.0), stirred evenly, and then transferred to a 100 mL hydrothermal kettle and kept in an oven at 180°C for 12 h. After cooling, the obtained samples were washed with deionized water until neutral, and dried to obtain gray Fluffy powder, XRD test shows that part of TiN is transformed into a new phase titanium oxynitride (TiN x o y ),Such as figure 1 Shown in A(b); scanning electron microscopy results show that the obtained powder has a three-dimensional chrysanthemum-like structure, such as figure 2 as shown in b. Indicates that the existence of strong base has an effect on the conversion of TiN to TiO 2 shape played an important role.

[0024] Adsorption performance test. Accurately weigh 5 mg of the prepared catal...

Embodiment 3

[0027] Example 3: Disperse 0.2 g TiN in 30 mL containing 0.03 mol / L HF and 0.1 mol / L H 2 o 2 10 mol / L sodium hydroxide aqueous solution (the molar ratio of TiN to concentrated alkali is 0.01, and the oxidants HF and H 2 o 2 The molar ratios were 2.6 and 1.0), stirred evenly, and then transferred to a 100 mL hydrothermal kettle and kept in an oven at 180°C for 12 h. After cooling, the obtained samples were washed with deionized water until neutral, and dried to obtain a white Fluffy powder, XRD test shows that almost all TiN is transformed into a new phase titanium oxynitride (TiN x o y ),Such as figure 1 Shown in A(c); scanning electron microscopy results show that the obtained powder has a three-dimensional chrysanthemum-like structure, such as figure 2 as shown in c. Indicates that the existence of strong base has an effect on the conversion of TiN to TiO 2 shape played an important role.

[0028] Adsorption performance test. Accurately weigh 5 mg of the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com