Resistance-type gas sensor with two support suspension beams and four-layer structure and method

A gas sensor, resistive technology, applied in the field of micro-electronic mechanical systems and gas sensing, can solve the problems of strict environmental conditions, expensive process equipment, high power consumption, achieve high mechanical strength, reduce the number of thin film layers, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

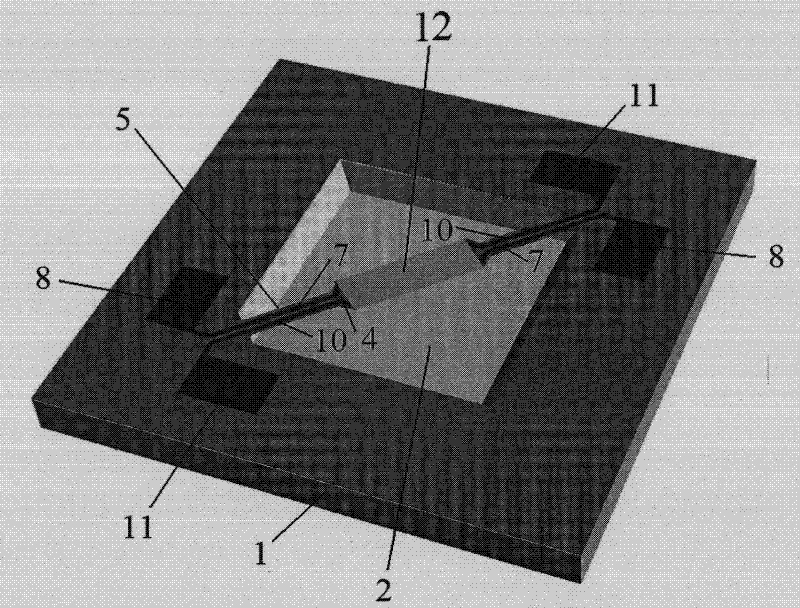

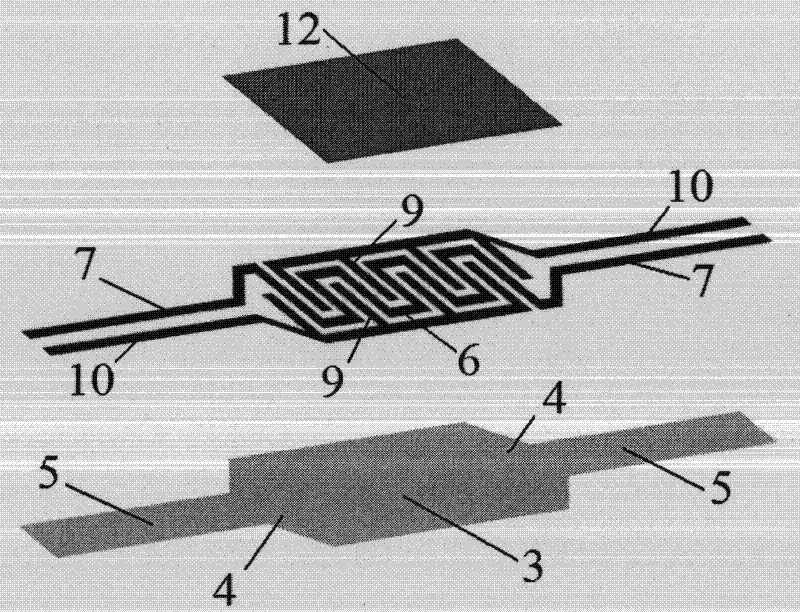

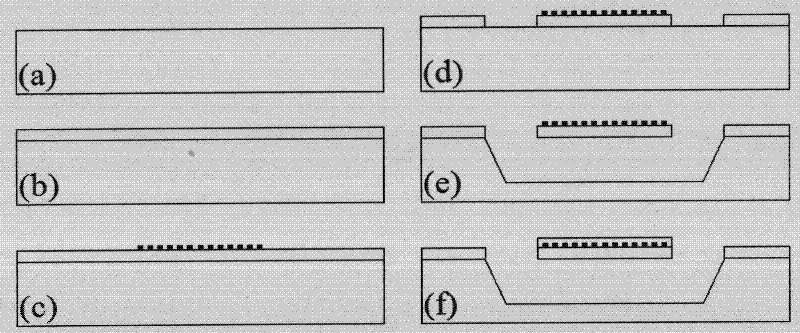

[0037] The structure schematic diagram of this embodiment sees figure 1 As shown, the specific production method is as follows:

[0038] 1. Select the substrate. A 4-inch double-sided polished silicon wafer with an N-type (100) surface is selected as a substrate, the resistivity is 3-8Ω·cm, the thickness of the silicon wafer is 350±10 microns, and the angle error of trimming is <1%.

[0039] 2. Make a composite film. A single-layer composite film is used to sequentially grow a layer of silicon oxide with a thickness of 0.5 microns and a layer of silicon nitride with a thickness of 0.3 microns by means of low-pressure chemical vapor deposition (LPCVD).

[0040] 3. Make heating resistance wire, power supply lead, power supply electrode, interdigital electrode, detection lead and detection electrode. Manufactured using a lift-off process. Thin resist lithography (photoresist thickness is 2.0 microns) defines the pattern of heating resistance wire, power supply lead, power sup...

Embodiment 2

[0045] The structure schematic diagram of this embodiment sees Figure 4 As shown, the specific production method is as follows:

[0046] 1. Select the substrate. A 4-inch double-sided polished silicon wafer with a P-type (100) surface is selected as the substrate, the resistivity is 3-8Ω·cm, the thickness of the silicon wafer is 350±10 microns, and the angle error of the edge trimming is less than 1%.

[0047] 2. Make a composite film. Using a single-layer composite film, a layer of silicon oxide with a thickness of 0.4 microns and a layer of silicon nitride with a thickness of 0.6 microns are sequentially grown by plasma enhanced chemical vapor deposition (PECVD).

[0048] 3. Make heating resistance wire, power supply lead, power supply electrode, interdigital electrode, detection lead and detection electrode. Manufactured by lift-off process. Thin photolithography (photoresist thickness is 2.0 microns) defines the pattern of heating resistance wire, power supply lead, p...

Embodiment 3

[0053] The structure schematic diagram of this embodiment sees Figure 5 As shown, the specific production method is as follows:

[0054] 1. Select the substrate. A 4-inch double-sided polished silicon wafer with a P-type (111) surface is selected as the substrate, the resistivity is 3-8Ω·cm, the thickness of the silicon wafer is 350±10 microns, and the angle error of the edge trimming is less than 1%.

[0055] 2. Make a composite film. Using a multi-layer composite film, a layer of silicon oxide with a thickness of 0.2 microns and a layer of silicon nitride with a thickness of 0.2 microns are sequentially deposited by low-pressure chemical vapor deposition (LPCVD), and then plasma-enhanced chemical vapor deposition (PECVD) A method of depositing a layer of silicon oxide with a thickness of 0.2 microns and a layer of silicon nitride with a thickness of 0.2 microns in sequence.

[0056] 3. Make heating resistance wire, power supply lead, power supply electrode, interdigital ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com