Method for treating polyether polyol wastewater

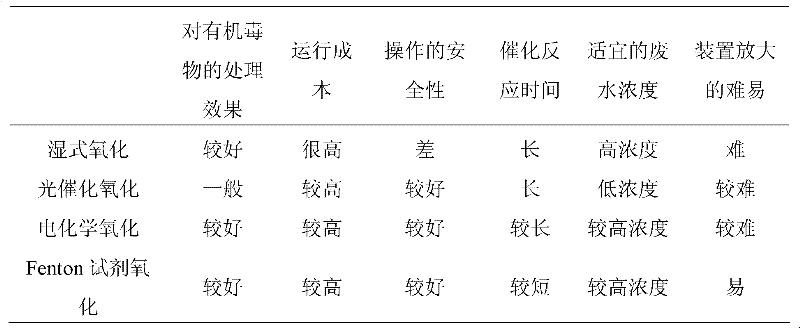

A polyether polyol and wastewater treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of insufficient mineralization of organic matter, reduced treatment efficiency, and safe operation. problems such as poor performance, to achieve the effect of facilitating industrial amplification, reducing processing costs, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

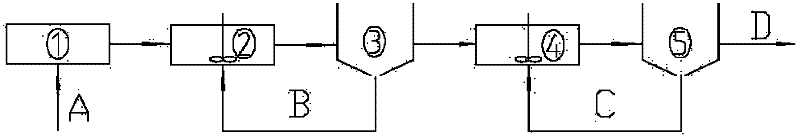

Method used

Image

Examples

Embodiment 1

[0039] (1). The polyether polyol production wastewater of a petrochemical enterprise with a COD of 3000mg / L is subjected to catalytic oxidation pretreatment, and the pH value of the wastewater is adjusted to 3 with a 2mol / L sulfuric acid solution. The catalyst uses Al 2 o 3, the ratio of the amount of catalyst added to the volume of the reaction column is 1:8, and the oxidant uses 2000mg / L of chlorine dioxide. The COD drops to about 2500mg / L, the B / C ratio increases to 0.47, and then the pH is adjusted to 7.0 with 5mol / L sodium hydroxide solution.

[0040] (2). The effluent after catalytic oxidation is passed into the biochemical enhancement pool. The sludge in the pool is aerobic sludge. The dissolved oxygen concentration is controlled at 0.9mg / L, the pH value is 7.8, the ORP value is -100mV, and the hydraulic retention time is 7d. ,, C: N: P = 300: 7: 1 for equipment dosing, adding nickel chloride, the nickel dosage is 0.01mg / L, so that the sludge in the pool undergoes biol...

Embodiment 2

[0043] (1). The polyether polyol production wastewater of a petrochemical enterprise with a COD of about 2300mg / L was subjected to catalytic oxidation pretreatment, and the pH value of the polyether polyol wastewater was adjusted to 5.8 with a 2mol / L hydrochloric acid solution. The catalyst was activated carbon. The ratio of the amount of catalyst added to the volume of the reaction column is 1:10, and the oxidant uses 2500mg / L of sodium chlorite. The operation process is referred to in the patent: an enhanced oxidation process and device for treating organic poisonous waste water (publication number: CN101148287), so that the waste water COD dropped to 1850mg / L, B / C ratio increased to 0.62, and then 2mol / L potassium hydroxide solution was used to adjust the pH to 8.

[0044] (2). The effluent after catalytic oxidation is passed into the biochemical enhancement tank. The sludge in the tank is anaerobic sludge. The dissolved oxygen is controlled at 0.2mg / L, the pH value is 6, th...

Embodiment 3

[0047] (1). The polyether polyol production wastewater of a petrochemical enterprise with a COD of 5000mg / L was subjected to catalytic oxidation pretreatment, and the pH value of the wastewater was adjusted to 4.0 with 4mol / L sulfuric acid solution. The catalyst was activated carbon, and the amount of catalyst added and the reaction The column volume ratio is 1:9, and the oxidant uses chlorine dioxide of 4000 mg / L. The operation process is referred to in the patent: an enhanced oxidation process and device for treating organic toxic waste water (publication number: CN101148287), which reduces the COD of waste water to 3860 mg / L , the B / C ratio was increased to 0.55, and then the pH was adjusted to 7.5 with 2mol / L sodium hydroxide solution.

[0048] (2). The effluent after catalytic oxidation is passed into the biochemical enhancement tank. The sludge in the tank is facultative anaerobic sludge. The dissolved oxygen concentration is controlled at 0.5mg / L, the pH value is 7.0, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com