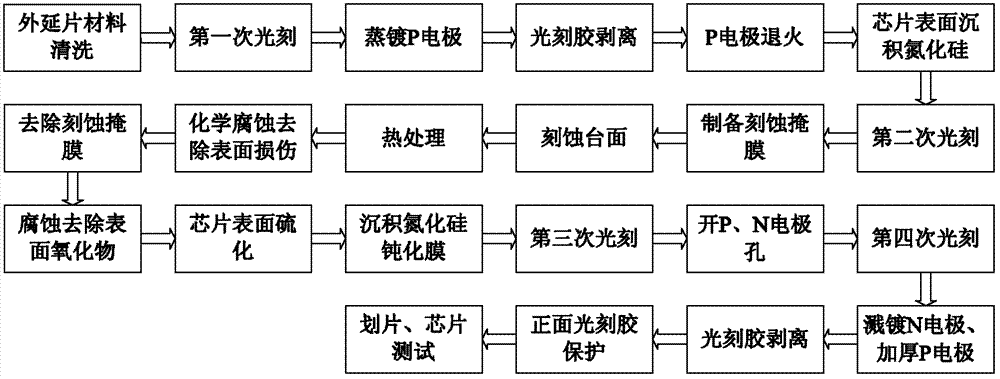

Manufacture method of table surface type indium gallium arsenic detector

A detector, indium gallium arsenide technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as passivation film damage and failure, achieve lattice repair, reduce surface fixed charge, reduce The effect of lattice damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation method of the present invention will be described in detail below.

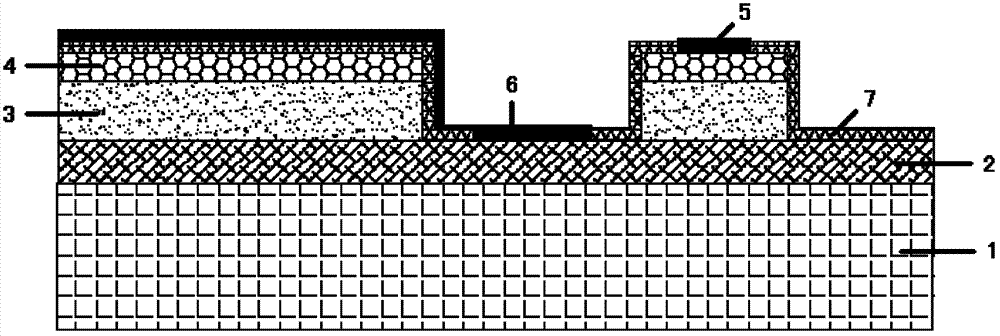

[0048] as attached figure 2 As shown, the epitaxial wafer used in the detector of this embodiment is an N-type InP layer 2 with a thickness of 1.5 μm grown sequentially on a semi-insulating InP substrate 1 with a thickness of 350 μm by gas source molecular beam epitaxy (GSMBE), doped Concentration greater than 2×10 18 cm -3 ; InGaAs absorber layer 3 with a thickness of 1.5 μm and a doping concentration of 3×10 16 cm -3; A P-type InP cap layer 4 with a thickness of 0.6 μm, with a doping concentration greater than 2×10 18 cm -3 . On the local area of the P-InP cap layer, Ti, Pt, and Au metal films are sequentially vapor-deposited as the P electrode region 5 and rapidly annealed, and then the P-InP / i-InGaAs / N-InP epitaxial wafer is etched to form a P- On the InP / i-InGaAs mesa, the chip surface and side walls are covered with silicon nitride passivation film 7, and on o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com