Cellulose improved moisture-permeable barrier composite film and preparation method thereof

A composite film and cellulose technology, which is applied in the field of cellulose-improved moisture-permeable barrier composite film and its preparation, to achieve excellent barrier properties, improve mechanical properties, and have market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

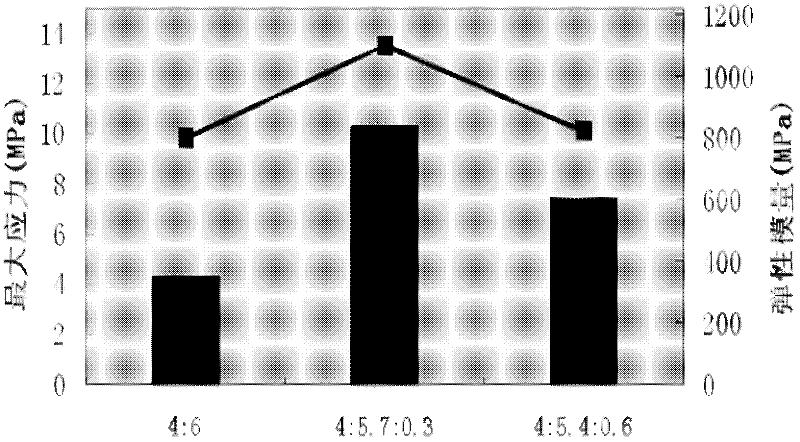

[0031] In this embodiment, the moisture-permeable barrier composite film is composed of polyvinyl chloride, sodium montmorillonite and cellulose acetate, wherein the sodium montmorillonite is dispersed in polyvinyl chloride as crystal phase powder to form a multi-phase solid film; The mass ratio of polyvinyl chloride powder, sodium montmorillonite and cellulose acetate is 4:5.7:0.3.

[0032] The preparation method of above-mentioned composite film is: get industrial polyvinyl chloride powder 3g and dissolve in 150mL tetrahydrofuran organic solvent, add cellulose acetate and sodium montmorillonite, polyvinyl chloride powder, sodium montmorillonite and acetic acid in the obtained clear liquid The mass ratio of cellulose is 4:5.7:0.3; oscillate ultrasonically for 20 minutes to make a suspension, cast it on a glass plate, and dry it to form a self-hanging film; keep it in a blast drying oven at 40°C for half an hour and then peel it off Thin film, the film thickness is 20μm~100μm,...

Embodiment 2

[0041] In this embodiment, the moisture-permeable barrier composite film is composed of polyvinyl chloride, sodium montmorillonite and cellulose acetate, wherein the sodium montmorillonite is dispersed in polyvinyl chloride as crystal phase powder to form a multi-phase solid film; The mass ratio of polyvinyl chloride powder, sodium montmorillonite and cellulose acetate is 4:5.4:0.6.

[0042] The preparation method of above-mentioned composite film is: get industrial polyvinyl chloride powder 3g and dissolve in 150mL tetrahydrofuran organic solvent, add cellulose acetate and sodium montmorillonite, polyvinyl chloride powder, sodium montmorillonite and acetic acid in the obtained clear liquid The mass ratio of cellulose is 4:5.4:0.6; oscillate ultrasonically for 20 minutes to make a suspension, cast it on a glass plate, and dry it to form a self-hanging film; keep it in a blast drying oven at 40°C for half an hour and then peel it off Thin film, the film thickness is 20μm~100μm,...

Embodiment 3

[0050] Other conditions are the same as in Example 1, and the difference is that hydroxypropyl methylcellulose is used to replace cellulose acetate to make a composite film, and the composite film obtained is similar to the composite film obtained in Example 1, and the composite film obtained in Comparative Example 1 Compared with thin films, it not only has excellent gas barrier properties, but also improves moisture permeability and mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com