P-type conductive zinc oxide film material and preparation method thereof

A technology of conductive zinc oxide and thin film materials, applied in the field of nanomaterials, can solve the problems of low carrier mobility, unstable ZnO acceptor impurities, and low carrier concentration, and achieve high carrier concentration and stable empty space. The effect of hole conduction and increasing doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

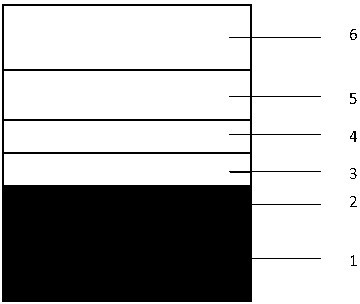

[0040] Such as figure 1 As shown, a p-type conductive zinc oxide thin film material includes a substrate 1 and an epitaxial layer grown on the substrate. A metal magnesium layer 2 and magnesium oxide are sequentially arranged between the substrate and the epitaxial layer from bottom to top. Layer 3, the first zinc oxide layer 4 and the second zinc oxide layer 5 with gradually increasing growth temperature; the epitaxial layer is a p-type BeZnO formed by doping an acceptor element N and doping Be atoms in a zinc oxide alloy: N-layer 6. The p-type ZnO conductive film is in a single crystal state through XRD test, and its rocking curve scan half-height FWHM is 0.09°. Among them, the material of the substrate 1 is sapphire. The thickness of the magnesium metal layer 2 is 0.5 nm. The thickness of the magnesium oxide layer is 2 nm. The thickness of the first zinc oxide layer 4 is 1.5 nm. The thickness of the second zinc oxide layer 5 is 30 nm. The thickness of the p-type BeZnO:...

Embodiment 2

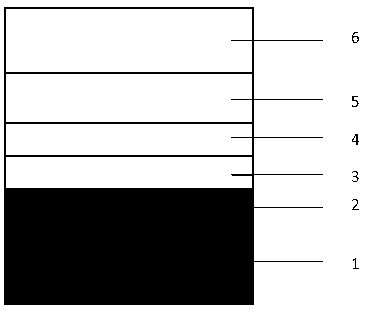

[0056] Such as figure 2 As shown, a p-type conductive zinc oxide thin film material includes a substrate 1 and an epitaxial layer grown on the substrate. A metal magnesium layer 2 and magnesium oxide are sequentially arranged between the substrate and the epitaxial layer from bottom to top. Layer 3, the first zinc oxide layer 4 and the second zinc oxide layer 5 with gradually increasing growth temperature; the epitaxial layer is a p-type BeZnO formed by doping an acceptor element N and doping Be atoms in a zinc oxide alloy: N-layer 6. The p-type ZnO conductive film is in a single crystal state through XRD testing, and its rocking curve scan half-height FWHM is 0.08°. Among them, the material of the substrate 1 is sapphire. The thickness of the magnesium metal layer 2 is 0.7 nm. The thickness of the magnesium oxide layer is 2 nm. The thickness of the first zinc oxide layer 4 is 2 nm. The thickness of the second zinc oxide layer 5 is 33 nm. The thickness of the p-type BeZnO...

Embodiment 3

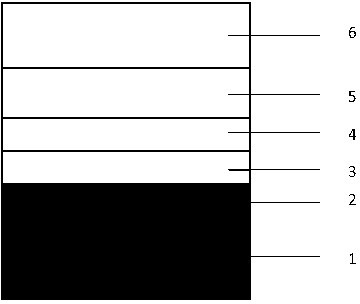

[0072] Such as image 3 As shown, a p-type conductive zinc oxide thin film material includes a substrate 1 and an epitaxial layer grown on the substrate. A metal magnesium layer 2 and magnesium oxide are sequentially arranged between the substrate and the epitaxial layer from bottom to top. Layer 3, the first zinc oxide layer 4 and the second zinc oxide layer 5 with gradually increasing growth temperature; the epitaxial layer is a p-type BeZnO formed by doping an acceptor element N and doping Be atoms in a zinc oxide alloy: N-layer 6. The p-type ZnO conductive film is in a single crystal state through XRD test, and its rocking curve scan half-height FWHM is 0.085°. Among them, the material of the substrate 1 is sapphire. The thickness of the magnesium metal layer 2 is 1 nm. The thickness of the magnesium oxide layer is 3 nm. The thickness of the first zinc oxide layer 4 is 2 nm. The thickness of the second zinc oxide layer 5 is 27 nm. The thickness of the p-type BeZnO:N l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com