Sample processing method for detecting boron in industrial silicon with graphite furnace atomic absorption spectrometry

A graphite furnace atomic absorption spectrometry technique is applied in the field of sample processing for the determination of boron in industrial silicon by graphite furnace atomic absorption spectrometry. The effect of low cost, improved sensitivity and fast analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

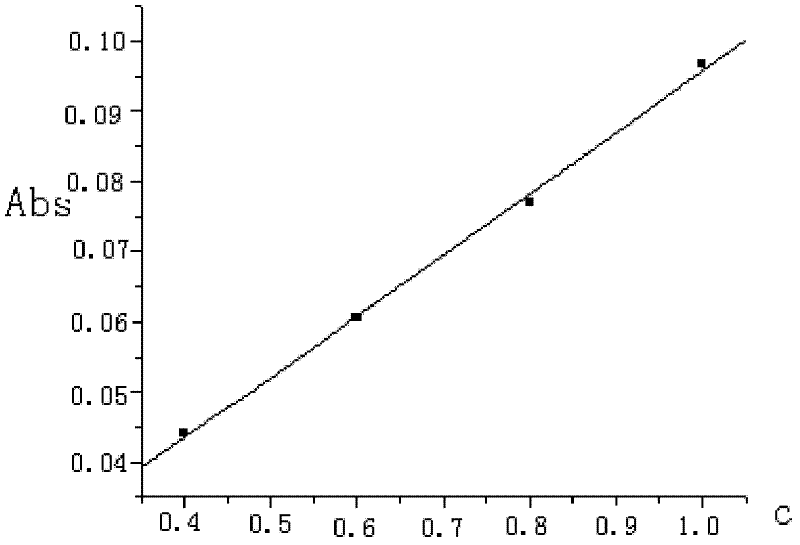

Image

Examples

Embodiment 1

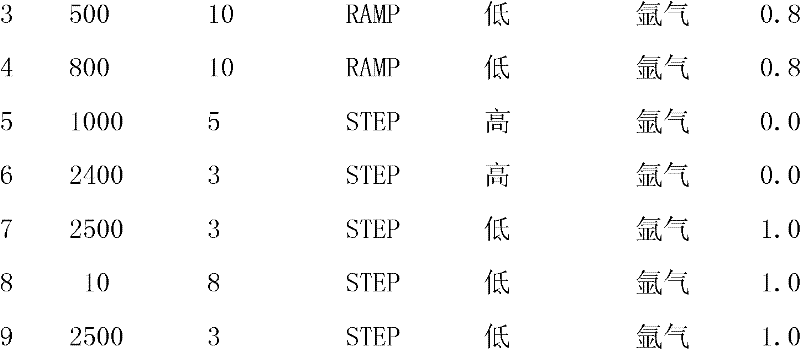

[0018] Example 1: The sample processing method for the determination of boron in industrial silicon by graphite furnace atomic absorption spectrometry includes the following steps:

[0019] (1) Weigh 0.995-1.005 grams of silicon powder crushed to more than 100 mesh into a 280-320mL polytetrafluoroethylene beaker, and flush a small amount of silicon powder attached to the inner wall of the cup to the bottom of the cup with pure water;

[0020] (2) Put the beaker on the hot plate and heat it until the water is about to evaporate. Remove the beaker, add 9-11mL of hydrofluoric acid, gently shake the beaker to make the silicon powder and hydrofluoric acid fully contact, and suck the nitric acid with a dropper ( HNO 3 : H 2 O=1:1), drop by drop into the beaker, add about 0.6mL, stop adding and wait for the reaction, if the reaction is relatively gentle, continue to drip nitric acid, and drop about 5mL;

[0021] (3) Put the beaker on a 100-150℃ electric hot plate to heat, continue heating u...

Embodiment 2

[0025] Example 2: Specific experimental test of the present invention:

[0026] 1.1 Instruments and equipment

[0027] WYS2200 atomic absorption spectrometer (Anhui Wanyi Technology), adjustable electric heating plate, WY802-II ultrapure water machine (Anhui Wanyi Technology), boron hollow cathode lamp (Beijing Nonferrous Metals General Institute), pyrolytic coating graphite tube ( Jilin Tianbao).

[0028] 1.2 Reagents and solutions

[0029] (1) Nitric acid, pure superior grade, 68-70%, products of Beijing Chemical Plant; (2) Hydrofluoric acid, pure superior grade, 40%, products of Beijing Chemical Plant; (3) High-purity deionized water. Resistivity ≥18MΩ.cm; (4) Ba standard solution: 1000μg / mL, Beijing Nonferrous Metals Institute; (5) Zirconium oxychloride analytically pure, ≥99.0% Sinopharm reagent; (6) B standard solution: 1000μg / mL , Beijing Nonferrous Metals General Institute; (7) Barium hydroxide premium grade pure Chinese medicine reagent.

[0030] 1.3 Standard solution prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com