Insulin carrying microsphere and preparation method thereof

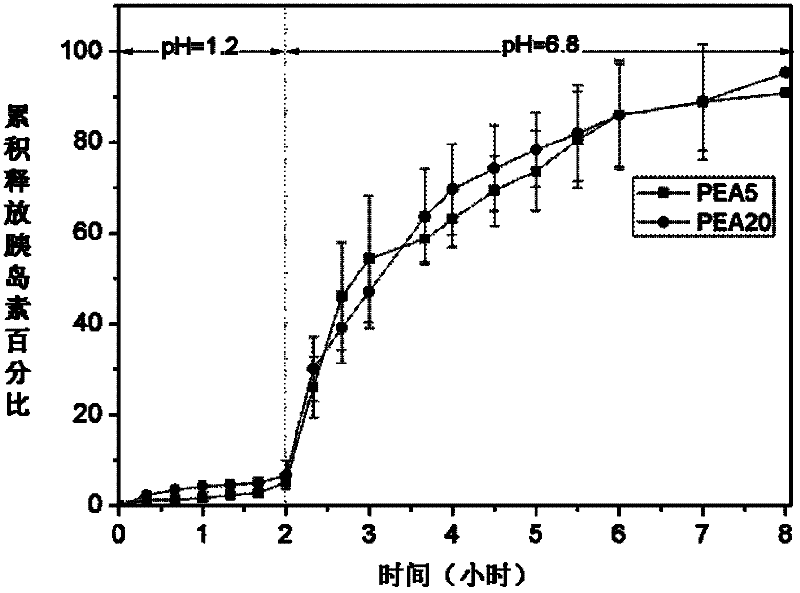

A technology of drug-loaded microspheres and insulin, which is used in pharmaceutical formulations, drug combinations, and non-active ingredients medical preparations, etc. problem, to achieve the effect of improving bioavailability, good pH sensitivity, and achieving release and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

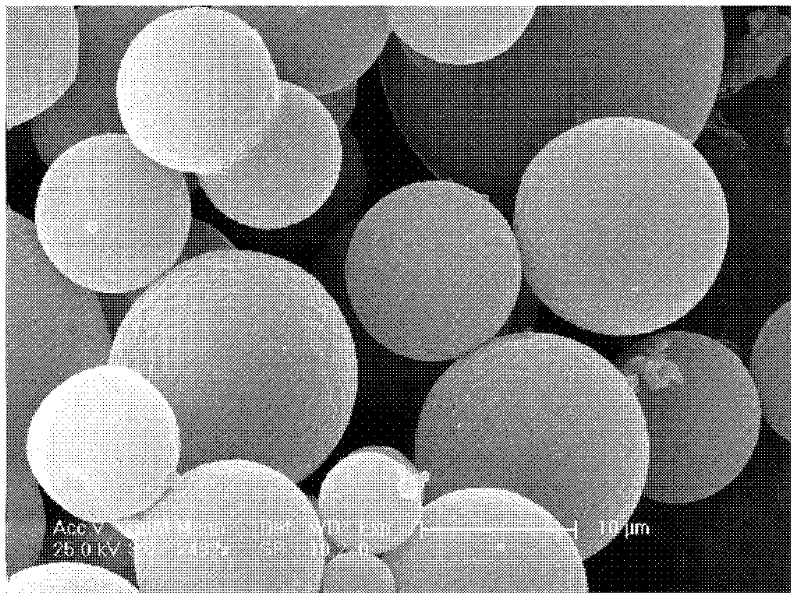

Image

Examples

preparation example Construction

[0041] Correspondingly, the present invention also provides a preparation method of insulin drug-loaded microspheres, comprising the following steps:

[0042] Insulin nanoparticles are placed in the N,N-dimethylformamide (DMF) solution of the polyester amide material with the structure of formula I to form a mixed solution;

[0043] Adding the mixed solution into corn oil, forming an emulsion after shearing and stirring;

[0044] Ether is added to the emulsion, and insulin drug-loaded microspheres are obtained after extraction, and the mass percentage of the insulin nanoparticles in the insulin drug-loaded microspheres is 4-10%, preferably 5-10%, more preferably 6% ~8%,

[0045]

[0046]

[0047] Wherein, x is the molar ratio of the repeating unit of the formula II structure to the repeating unit of the formula III structure, x is 0-0.5, preferably 0.05-0.5, more preferably 0.1-0.4, more preferably 0.2-0.3, n is Polymerization.

[0048]The insulin nanoparticles used i...

Embodiment 1

[0067] After polycondensation of the monomers of the formula IV, the monomers of the formula V and the monocondensation of the formula VI, the benzyl protecting group is removed with hydrobromic acid to obtain a polyester amide polymer material with a large number of carboxyl groups in the side chain.

[0068] The specific experimental steps are:

[0069] 10 mmol, 0.5 mmol and 9.5 mmol of monomers of formula IV structure, formula V structure and formula VI structure were placed in a round bottom flask with magnetic stirring, and dry dimethyl Acetamide (DMA) was dissolved, and after the temperature was raised to 80°C, 3.2mL of dry triethylamine solution was slowly added dropwise, and after 24 hours of polycondensation, it was settled with glacial ethyl acetate and drained;

[0070] Take 1 gram of the initial product obtained by polycondensation of the three monomers and fully dissolve it in 10ml of dichloroacetic acid, add 2ml of hydrobromic acid in 33% acetic acid solution, st...

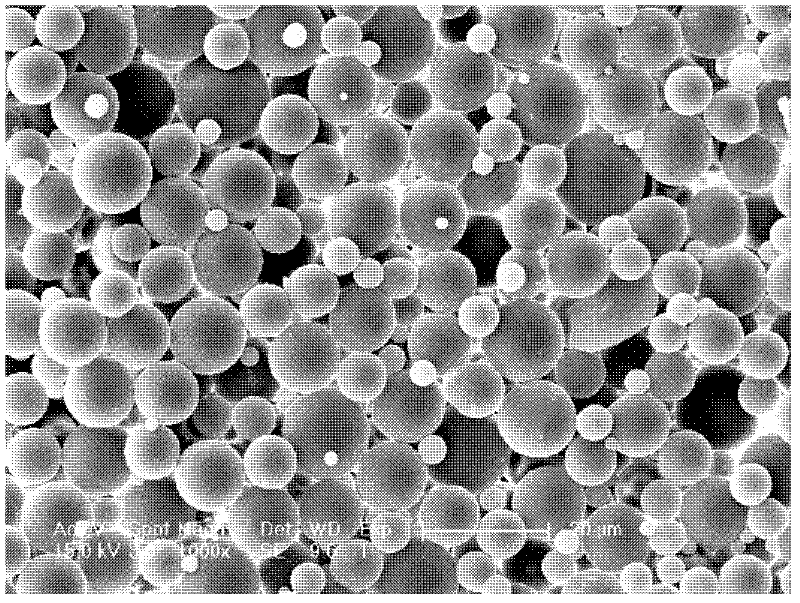

Embodiment 2

[0072] Place 10 mmol, 2 mmol and 8 mmol of monomers of formula IV structure, formula V structure and formula VI structure respectively in a round bottom flask with magnetic stirring, add dry DMA to dissolve , heated up to 80°C, slowly added dropwise 3.2ml of dry triethylamine solution, reacted for 24 hours, settled with glacial ethyl acetate, and drained;

[0073] Take 1 gram of the initial product obtained by polycondensation of the three monomers and fully dissolve it in 10ml of dichloroacetic acid, add 2ml of hydrobromic acid in 33% acetic acid solution, stir and react at room temperature for 4 hours, and settle the reactant with excess acetone out, and then repeatedly washed with ether and acetone to remove residual hydrobromic acid, and dried in a vacuum oven to obtain the polyester amide material of formula I structure, namely PEA20, and the performance parameters are shown in Table 1.

[0074] The performance parameter of the polyester amide material that table 1 embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com