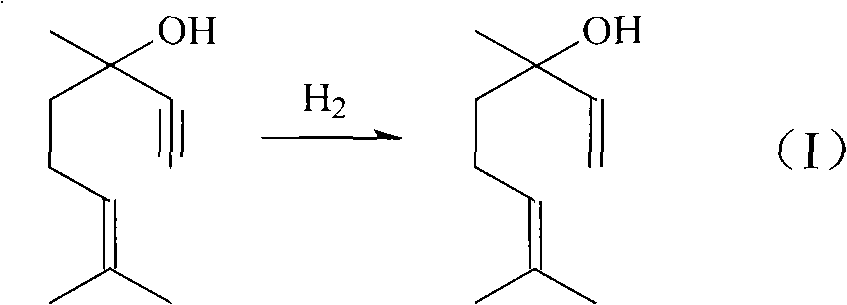

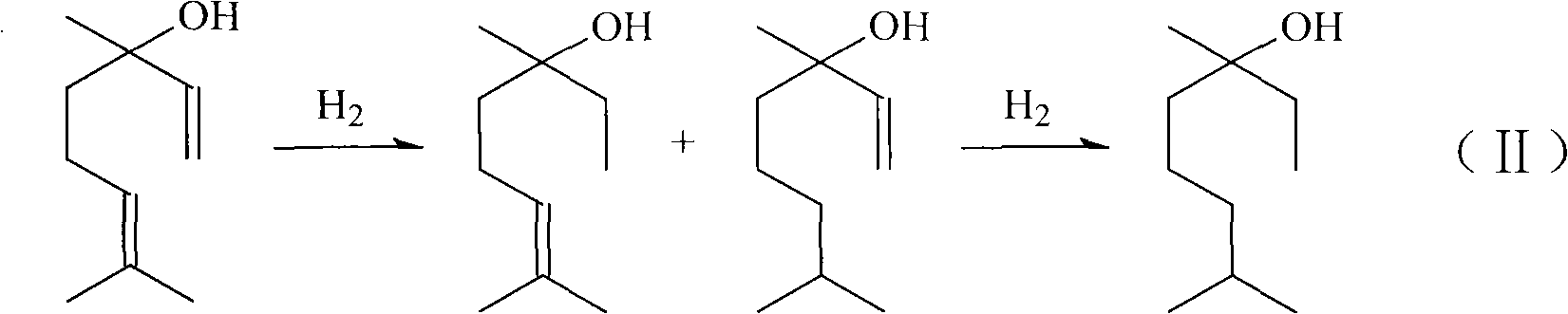

Fixed bed catalyst for preparing linalool by selective hydrogenation of dehydrolinalool

A fixed-bed catalyst and dehydrolinalool technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrogenation preparation, etc., can solve the problem of increasing residence time, inability to obtain catalyst load, Increase the complexity of production equipment and operating processes, etc., to achieve the effect of improving the space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0034] Using aluminum hydroxide powder as the raw material, the carrier slurry is first prepared, then shaped and granulated, and then calcined at 500-1100℃ for 2-5 hours. The particle size range is 3-5mm, and the BET specific surface area is in the range of 50~150m 2 / g of spherical Al 2 O 3 Carrier.

[0035] Prepare the impregnation solution with the required proportions of palladium chloride, lead nitrate and bismuth nitrate, and then add the Al 2 O 3 The carrier is placed in the immersion solution and stirred evenly. Standing and aging for 10-15 hours, drying and calcining to obtain a catalyst precursor. The firing temperature is controlled at 400-600°C, and the firing time is controlled at 2 to 3 hours.

[0036] The catalyst precursor is immersed in an equal volume of sodium ethylenediaminetetraacetate (EDTA) aqueous solution, and the EDTA concentration in the aqueous solution is controlled to be 0.3-3.0wt.%. Subsequently, the catalyst precursor with adsorbed EDTA was dried ...

Embodiment 11~26

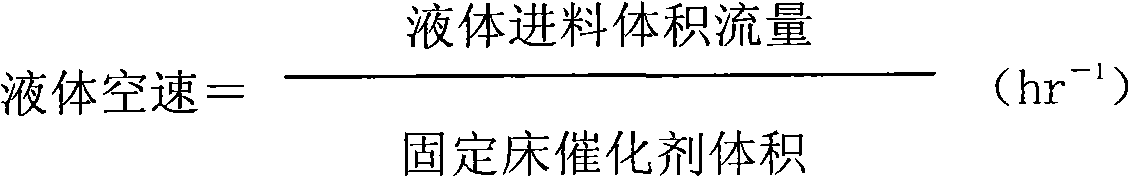

[0043] According to Examples 1-10, a fixed-bed reactor was obtained. Under the condition of continuously feeding hydrogen, the reactor was lowered to the temperature required for the reaction, and the hydrogen pressure was adjusted. The C2-C4 fatty alcohol is used as a solvent, the solvent is mixed with dehydrolinalool in a required ratio (solvent ratio), and then the liquid phase passes through the catalyst bed, maintaining suitable reaction conditions for continuous hydrogenation to prepare linalool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com