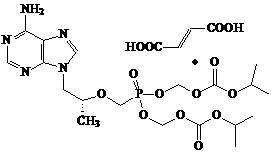

Preparation method of antiviral drug tenofovir disoproxil fumarate intermediate chloromethyl isopropyl carbonate

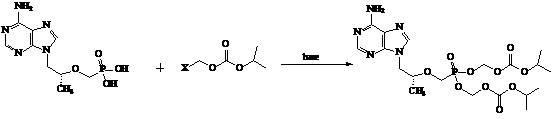

A kind of technology of chloromethyl isopropyl carbonate and tenofovir disoproxil, applied in the field of preparation of intermediates, can solve the complex steps, high cost, rarely reported chloromethyl chloroformate or chloromethyl isopropyl Carbonate synthesis and other problems, to achieve the effects of high reactivity, improved yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

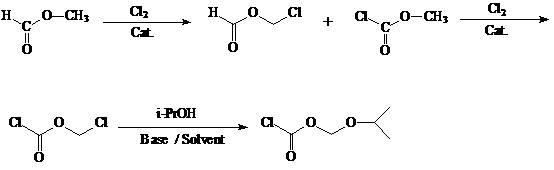

[0040] 1. Synthesis of methyl chloroformate and chloromethyl formate mixture:

[0041] Under nitrogen protection, with magnetic stirring, add 500 g methyl formate and 4 g AIBN into a 1000 mL four-neck flask, connect with condensed water, heat directly to reflux state, pass Cl 2 , the tail gas uses 20% NaOH solution to absorb the discharged HCl gas. It takes about 8-10h to complete the first step of chlorination of methyl formate. On gas chromatography (GC), it was completely converted into methyl chloroformate and chloromethyl formate with a ratio close to 1:1. The mixed product is reserved for later use.

[0042] 2. Synthesis of chloromethyl chloroformate:

[0043] Add the entire mixture of methyl chloroformate and chloromethyl formate obtained above, add 4g of AIBN again, and feed chlorine gas again under reflux (60-80°C), when the main peak of chloromethyl chloroformate reaches 75-80% content At this time, the dichloromethyl chloroformate has reached about 2%, and ...

Embodiment 2

[0047] 1. Synthesis of methyl chloroformate and chloromethyl formate mixture:

[0048] Under nitrogen protection, with magnetic stirring, add 500 g methyl formate and 4 g BPO into a 1000 mL four-necked flask, connect with condensed water, heat directly to reflux state, pass Cl 2 , the tail gas uses 20% NaOH solution to absorb the discharged HCl gas. It takes about 8-10h to complete the first step of chlorination of methyl formate. On GC, it is completely converted to methyl chloroformate and chloromethyl formate, the ratio of which is close to 1:1. The mixed product is reserved for later use.

[0049] 2. Synthesis of chloromethyl chloroformate:

[0050]Add the entire mixture of methyl chloroformate and chloromethyl formate obtained above, add 4g of BPO again, and feed chlorine gas again under reflux (60-80°C), when the main peak of chloromethyl chloroformate reaches 75-80% content At this time, the dichloromethyl chloroformate has reached about 2%, and the reaction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com