Composite material based on nanometer, preparation method of composite material and application in flexible energy storage device

A nano-composite material and nano-technology, which is applied to conductive materials, capacitors, electrical components and other directions dispersed in non-conductive inorganic materials, can solve the problems of difficult bending and deformation of energy storage devices, and cannot meet the development needs of flexible electronic devices. The effect of improving the specific capacity per unit mass, good mechanical strength and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

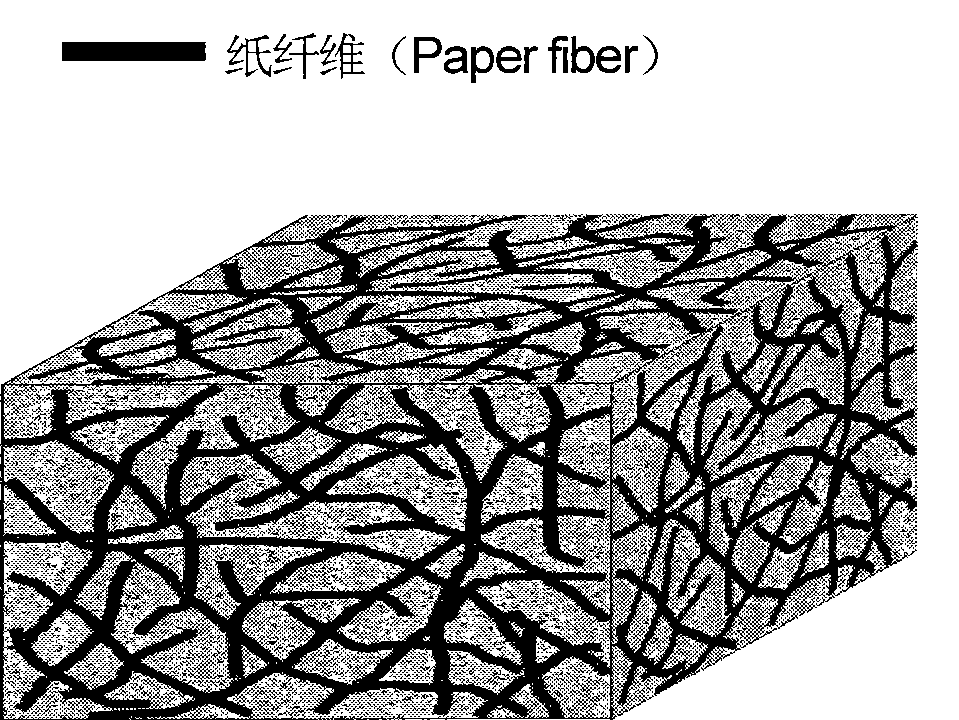

[0036] By ultrasonic dispersion method or stirring dispersion method, graphene (1~50 layers) is dissolved in NMP (nitromethylpyrrolidone) solution, forms stable graphene solution (solution concentration 0.01~1mg / mL); In this embodiment , the concentration of graphene in the solution is 0.03mg / mL.

[0037] Use commercial filter paper (medium-speed qualitative filter paper) as the filter medium, filter 300mL graphene solution by vacuum filtration, and repeatedly filter until the black graphene solution becomes colorless, take out the filter paper and dry it at 120°C for 12 hours to obtain graphene / Paper Nanocomposites.

[0038] In the graphene / paper nanocomposite material of this embodiment, graphene accounts for 7.5% by mass of the composite material, and the rest is paper fiber; the composite material is a disc with a radius of 18 mm and a thickness of 200 μm.

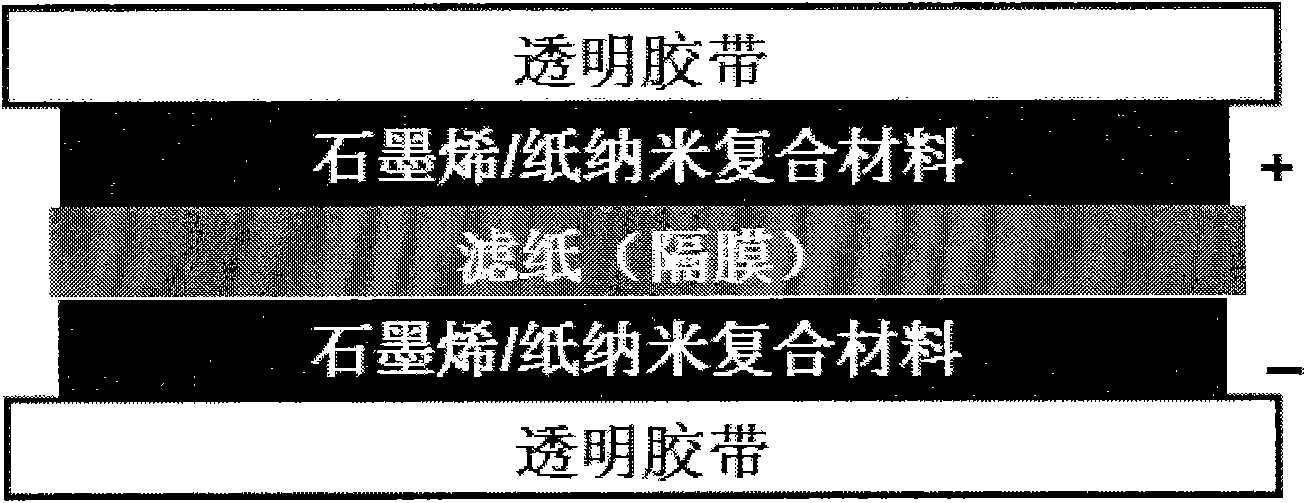

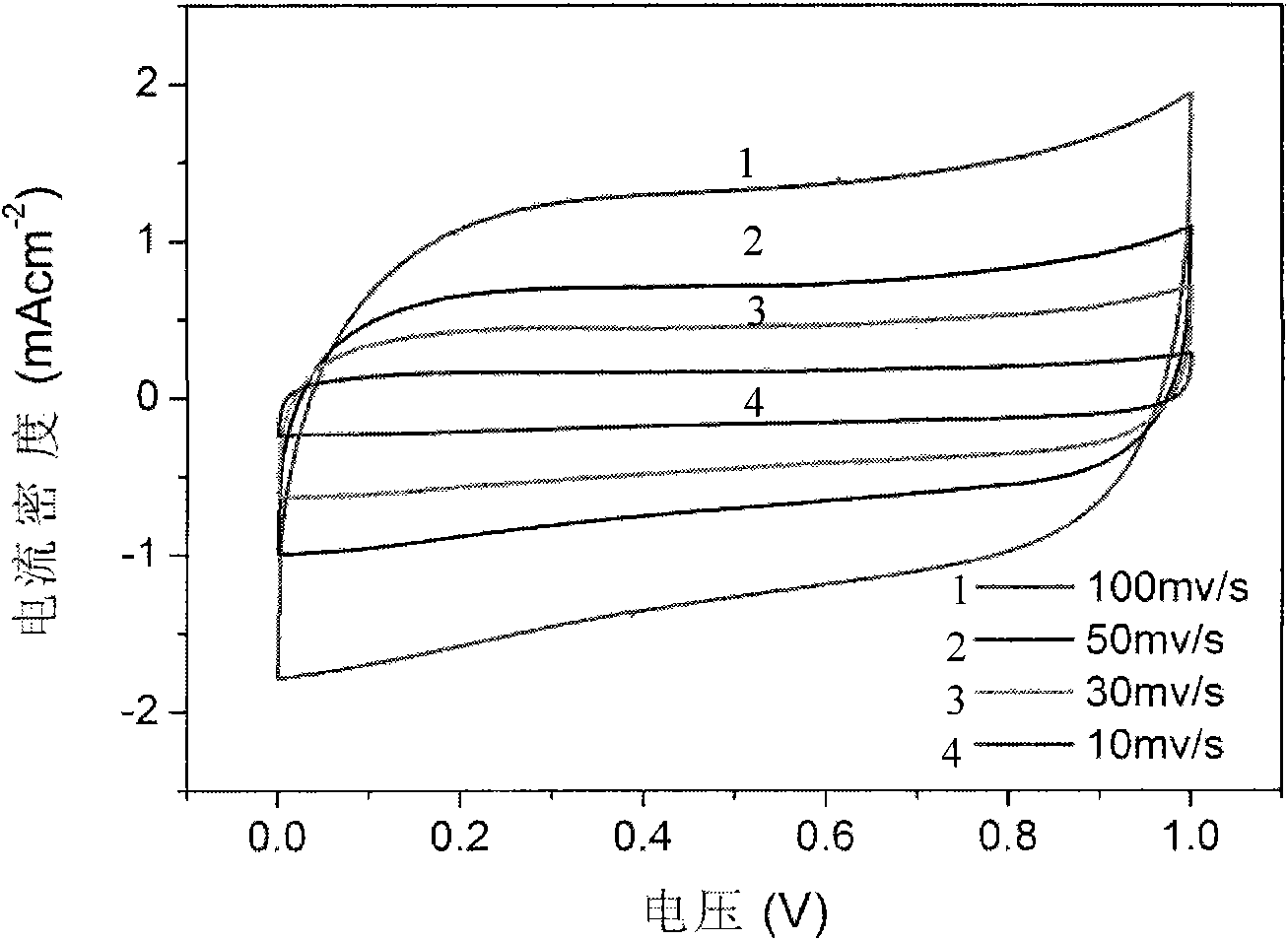

[0039] The obtained nanocomposite material was cut into discs (13 mm in diameter) as electrode sheets, Au sheet a...

Embodiment 2

[0045] The difference from Example 1 is:

[0046] By ultrasonic dispersion method or stirring dispersion method, graphene (1~50 layers) is dissolved in NMP (nitromethylpyrrolidone) solution, forms stable graphene solution; In the present embodiment, the concentration of graphene in the solution is 0.3 mg / mL.

[0047] Use commercial filter paper (medium-speed qualitative filter paper) as the filter medium, filter 150mL graphene solution by vacuum filtration, and repeatedly filter until the black graphene solution becomes colorless, take out the filter paper and dry it at 120°C for 12 hours to obtain different graphites Graphene / paper nanocomposites with high alkene content.

[0048] In the graphene / paper nanocomposite material of this embodiment, graphene accounts for 3.1% by mass of the composite material, and the rest is paper fiber; the composite material is a disc with a radius of 18 mm and a thickness of 190 μm.

[0049] In this embodiment, the tensile strength of the co...

Embodiment 3

[0051] The difference from Example 1 is:

[0052] By ultrasonic dispersion method or stirring dispersion method, graphene (1~50 layers) is dissolved in NMP (nitromethylpyrrolidone) solution, forms stable graphene solution; In the present embodiment, the concentration of graphene in the solution is 0.3 mg / mL.

[0053] Use cotton fiber as the filter medium, filter 300mL graphene solution by vacuum filtration, and repeatedly filter until the black graphene solution becomes colorless, take out the cotton fiber and dry it at 120°C for 12 hours to obtain a graphene / cotton fiber nanocomposite Material.

[0054] In the graphene / cotton fiber nanocomposite material of this embodiment, graphene accounts for 5.6% by mass of the composite material, and the rest is cotton fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com