Preparation method of supercapacitor based on grapheme-carbon nanotube composite material

A technology of supercapacitors and carbon nanotubes, applied in capacitors, electrolytic capacitors, liquid electrolytic capacitors, etc., can solve the problems affecting the preparation of capacitors, low yield, long time, etc., and achieve good thermal and chemical stability, electrical conductivity Good performance and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

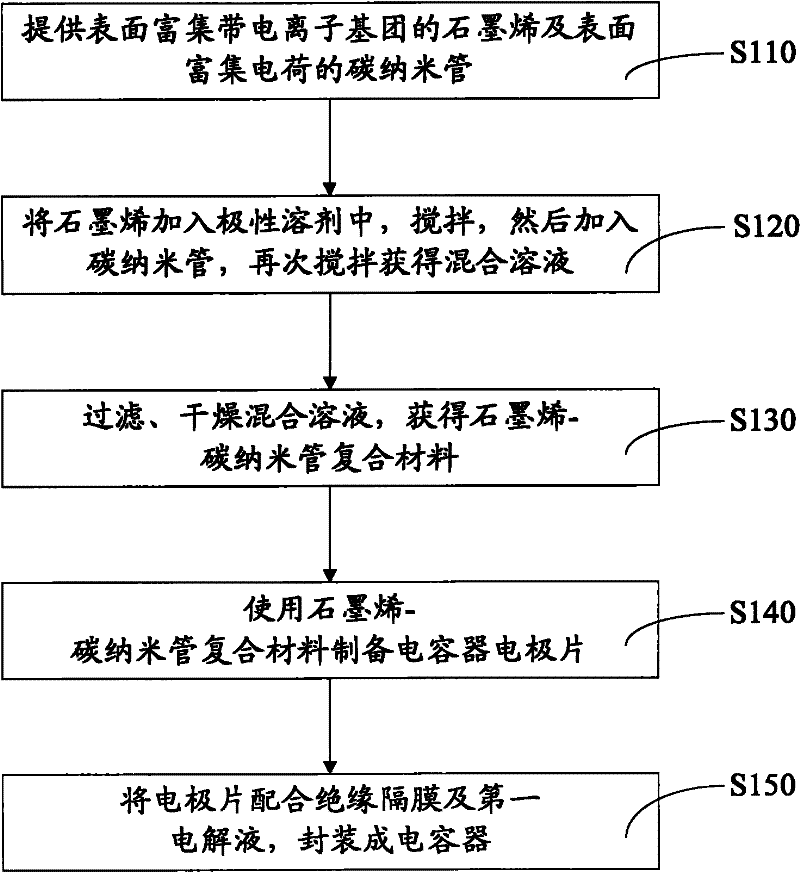

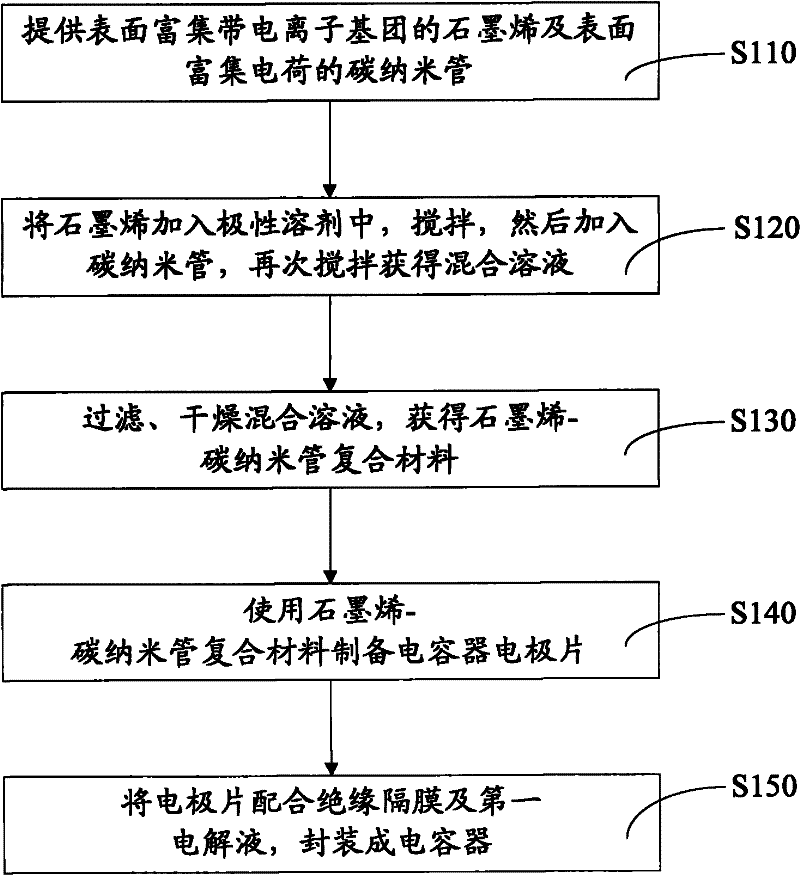

[0026] Such as figure 1 Shown, the preparation method based on graphene-carbon nanotube composite supercapacitor of one embodiment mainly comprises the following steps:

[0027] S110: Provide graphene with charged ionic groups on the surface and carbon nanotubes with charged ions on the surface. Wherein, the electrical properties of the charged ionic groups on the surface of graphene and the enriched charge anisotropy on the surface of carbon nanotubes; preferably, the molar ratio of graphene to carbon nanotubes is 1:1.

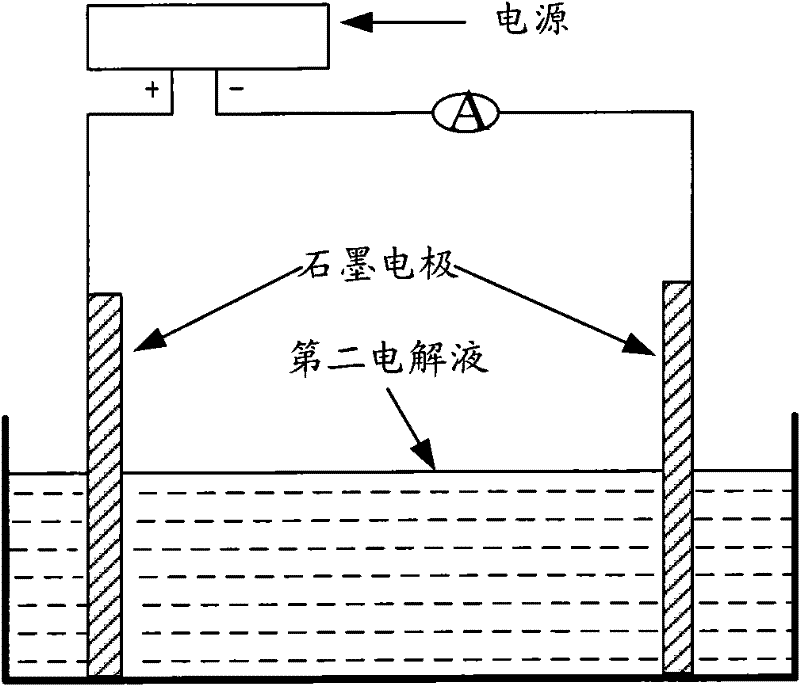

[0028] Graphene enriched with charged ionic groups on the surface can be prepared, but not limited to, using the following graphite rod electrolysis method: such as figure 2 As shown, two graphite rods are used as electrodes, placed in the second electrolytic solution, and electrolyzed at a power supply voltage of 5-20V for 0.5-6h to obtain a mixed solution of graphene enriched with charged ionic groups on the surface; then the The mixed solution is centri...

Embodiment 1

[0043] Embodiment 1: graphite rod → graphene → graphene-carbon nanotube composite material → electrode sheet → supercapacitor:

[0044] (1) Graphite rods: graphite rods with a purity of 99.9%.

[0045] (2) Graphene: The preparation of graphene enriched with charged ion groups on the surface is to insert two high-purity graphite rods in parallel into an aqueous solution containing ammonium nitrate, control the voltage at 5V, and electrolyze for 30 minutes. Corroded, black products are gradually generated, and the anions in the electrolyte are gradually gathered at the anode, and the electrolysis is continued for 3 hours, and the obtained suspension is centrifuged to remove the agglomerated precipitate, and washed repeatedly with deionized water and absolute ethanol, at 80 °C for 2 hours under vacuum to obtain 3 - of graphene.

[0046] (3) Graphene-carbon nanotube composite material: the band NO obtained in the above (2) 3 - Graphene was dissolved in an aqueous solution, so...

Embodiment 2

[0050] Embodiment 2: graphite rod→graphene→graphene-carbon nanotube composite material→electrode sheet→supercapacitor:

[0051] (1) Graphite rods: graphite rods with a purity of 99.9%.

[0052] (2) Graphene: the preparation method of the graphene that the surface is enriched with charged ion group is that two high-purity graphite rods are inserted in parallel in the electrolytic solution that volume ratio is 1: 1 imidazolium hexafluorophosphate and water, Control the voltage at 10-20V, after 30 minutes of electrolysis, the graphite rod of the anode is inserted by the cation in the ionic liquid, and the exfoliated black single-layer graphene product is gradually generated, and the electrolysis is continued for 6 hours, and the obtained suspension is centrifuged to obtain The agglomerated precipitate was removed, washed repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C for 4 hours to obtain graphene with imidazolyl cations.

[0053] (3) Graphene-car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com