Production method of low-noise germanium-silicon heterojunction bipolar transistor

A technology of heterojunction bipolar and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of increased 1/f noise of noisy devices, low current amplification of HBT, and increased white noise of devices, etc. , to achieve the effect of improving noise characteristics, reducing defect density and surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

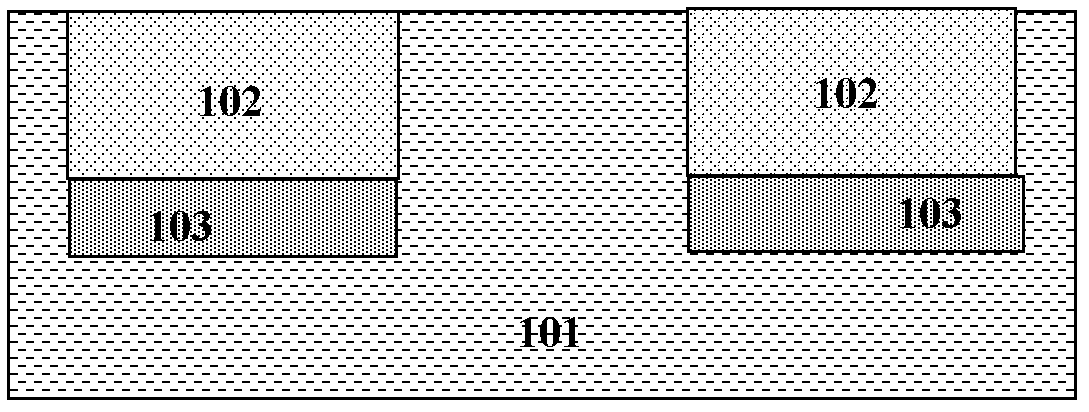

[0029] In the present invention, the emitter of the silicon germanium HBT still adopts the conventional polysilicon thin film, but after carrying out ion implantation doping to the polysilicon emitter and performing rapid thermal annealing impurity redistribution, the polysilicon emitter is carried out pre-amorphization ion implantation ( PAI), and rapid annealing (RTA), to achieve recrystallization of the amorphized emitter, to generate a single crystal layer, so that the emitter / base junction is composed of single crystal silicon / single crystal germanium silicon, improving the noise characteristics of the device. Because the diffusion and redistribution of impurities in the emitter has been completed before PAI, the recrystallization of PAI and RTA will not affect the distribution of impurities in the emitter, and will not change the current amplification factor of HBT.

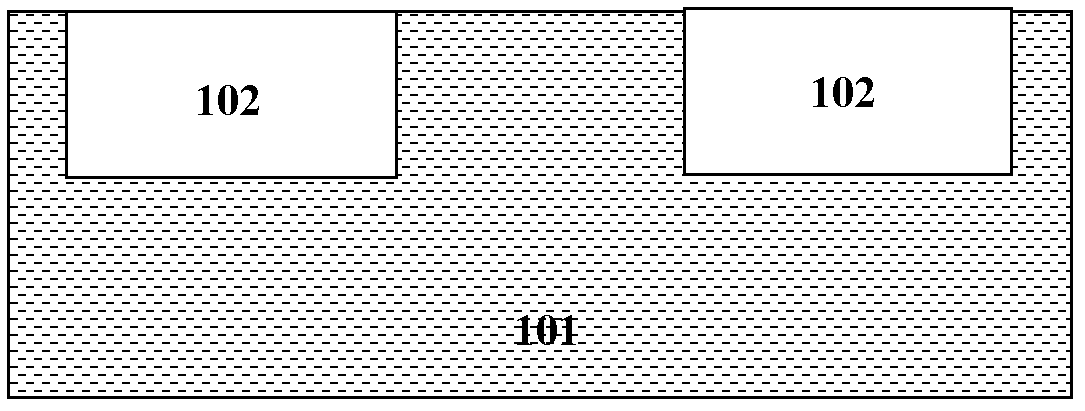

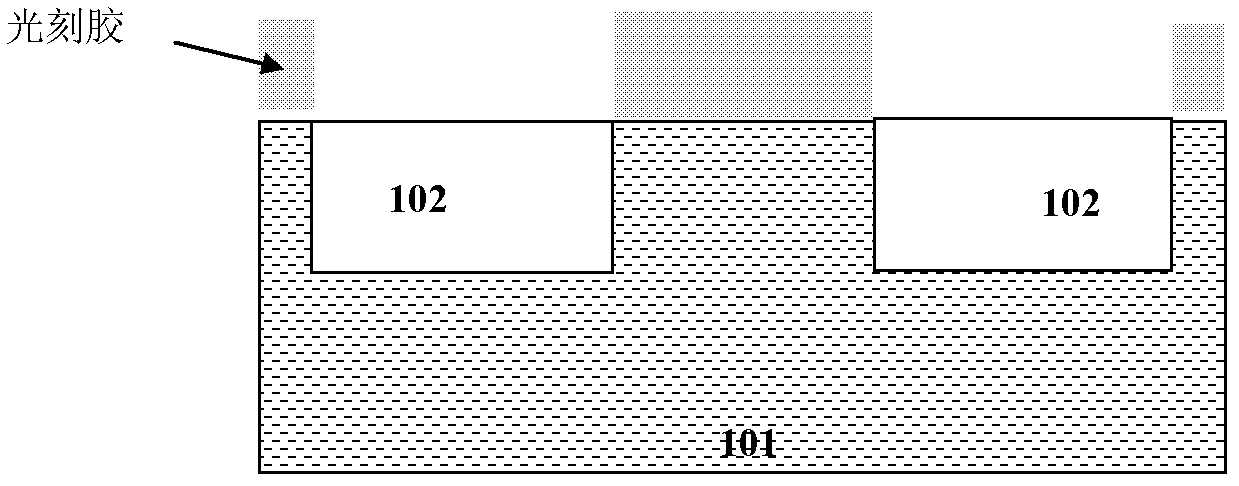

[0030] The manufacturing process of the low-noise SiGe HBT may include the following steps:

[0031] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com