Magnetic molecularly imprinted polymer for separating atrazine, and preparation method for magnetic molecularly imprinted polymer

A technology of imprinted polymers and magnetic molecules, which is applied in the field of magnetic molecular imprinted polymers for separating atrazine and its preparation, can solve the problems of easy shedding and leakage of magnetic fluid, and achieve good stability, cheap and easy-to-obtain raw materials, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Fe 3 o 4 : by chemical co-precipitation method

[0033] (1) Weigh FeSO at a molar ratio of 1:1.75 4 ·7H 2 O and FeCl 3 ·6H 2 O was added to a 100mL reaction bottle, and 20mL of N-filled 2 Deoxygenated water, N-filled 2 React for 30min, add 10mLNH dropwise to the constant pressure funnel 3 ·H 2 O, react in an oil bath at 65°C for 2h;

[0034] (2) Add 1.0 g of citric acid, react for 1.5 h, add cellulose acetate particles to the above mixed solution, and magnetically stir for 2 h, the mass concentration of cellulose acetate in the mixed solution is 10%;

[0035] (3) After the reaction is completed, wash with ethanol and water to neutrality respectively, and dry under vacuum at 60° C. overnight;

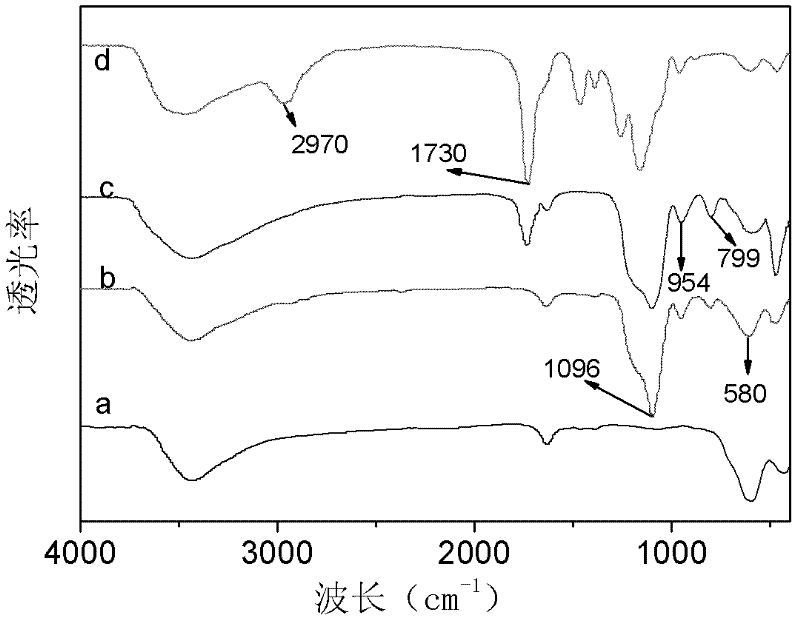

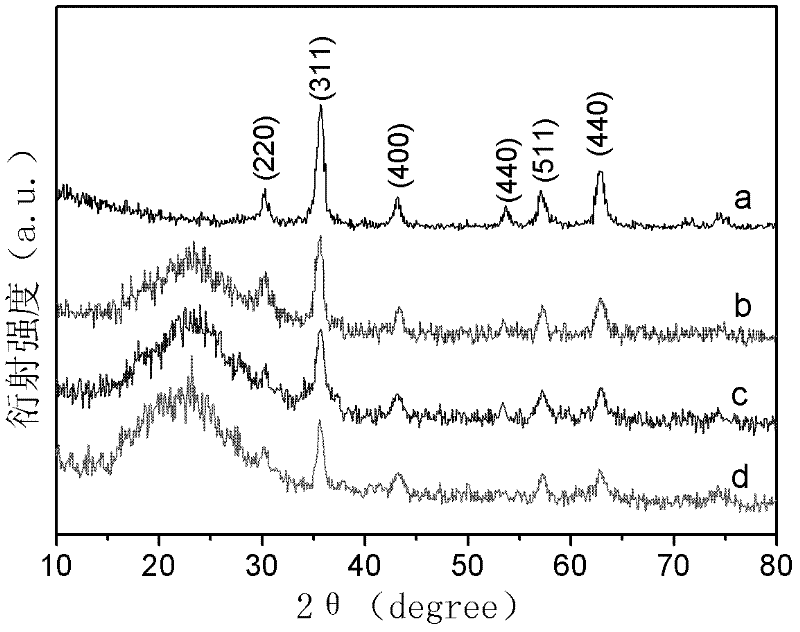

[0036] Fe 3 o 4 The infrared spectrum of figure 1 As shown in a, 580cm -1 The nearby stretching vibration absorption peak is the characteristic absorption peak of Fe-O bond; Fe 3 o 4 X-ray diffraction such as figure 2 As shown, Fe appeared at 2θ=30.3...

Embodiment 2

[0038] Fe 3 o 4 SiO 2 Preparation and activation:

[0039] (1) Fe prepared in 0.1g embodiment 1 3 o 4 Disperse in 120mL ethanol and 10mL water, add 1mL NH 3 ·H 2 O. 2mL TEOS (tetraethyl orthosilicate), stirred at 25°C for 24h;

[0040] (2) Magnetic separation, washing with ethanol and water respectively, vacuum drying at 60°C, 0.1g Fe 3 o 4 SiO 2 , add 10mL of HCl with a concentration of 10%, reflux in an oil bath at 50°C for 6h, wash, and dry under vacuum at 60°C to obtain activated Fe 3 o 4 SiO 2 .

[0041] Fe 3 o 4 SiO 2 The infrared spectrum of figure 1 As shown in b, 1096cm -1 The antisymmetric stretching vibration absorption peak of nearby Si-O-Si, 954cm -1 The characteristic vibration peak of Si-O in the nearby Si-OH bond and the 799cm -1 The bending vibration absorption peaks of nearby Si-O-Si are all SiO 2 The main characteristic absorption peaks of the structure, indicating that the Fe 3 o 4 The surface of magnetic microspheres was successfully ...

Embodiment 3

[0043] Fe 3 O4SiO 2 Modifiers:

[0044] (1) get the Fe activated in 0.3g embodiment 2 3 o 4 SiO 2 Nanoparticles dispersed in 100mL toluene;

[0045] (2) Add 2mL MPS (KH570γ-methacryloxypropyltrimethoxysilane), 2 Under ambient conditions, reflux at 65°C for 12 hours;

[0046] (3) Wash three times with dimethyl sulfoxide and ethanol respectively, and dry to obtain composite magnetic nanoparticles Fe 3 o 4 SiO 2 -MPS.

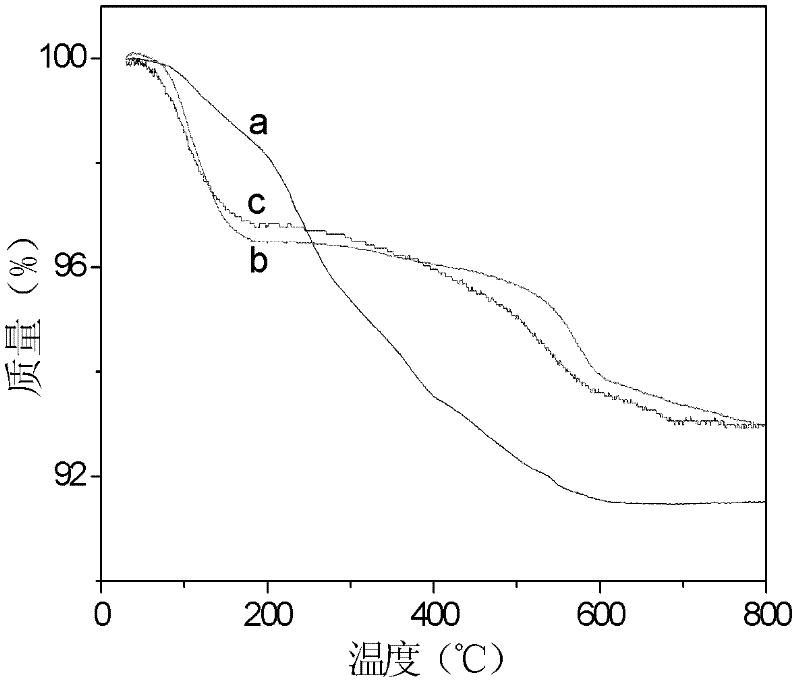

[0047] in Fe 3 o 4 SiO 2 Surface modified with MPS from Figure 5 Composite magnetic nanoparticles Fe can be seen in 3 o 4 SiO 2 - MPS saturation susceptibility compared to Fe 3 o 4 SiO 2 Microspheres increased, possibly due to the binding of MPS to Fe 3 o 4 SiO 2 surface; from Figure 5 Fe can be seen in 3 o 4 SiO 2 -The thermal stability of MPS is different from that of Fe 3 o 4 SiO 2 Quite, both than Fe 3 o 4 Good thermal stability; Figure 8 The TEM image also shows that the experiment successfully synthesized Fe 3 o 4 The mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com