High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

An inorganic composite, antibacterial and antifungal technology, applied in antifouling/underwater coatings, coatings, latex paints, etc., can solve the problems of large specific surface area of nanoparticles and difficulty in effective dispersion, achieve easy dispersion, and improve anti-aging performance , the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

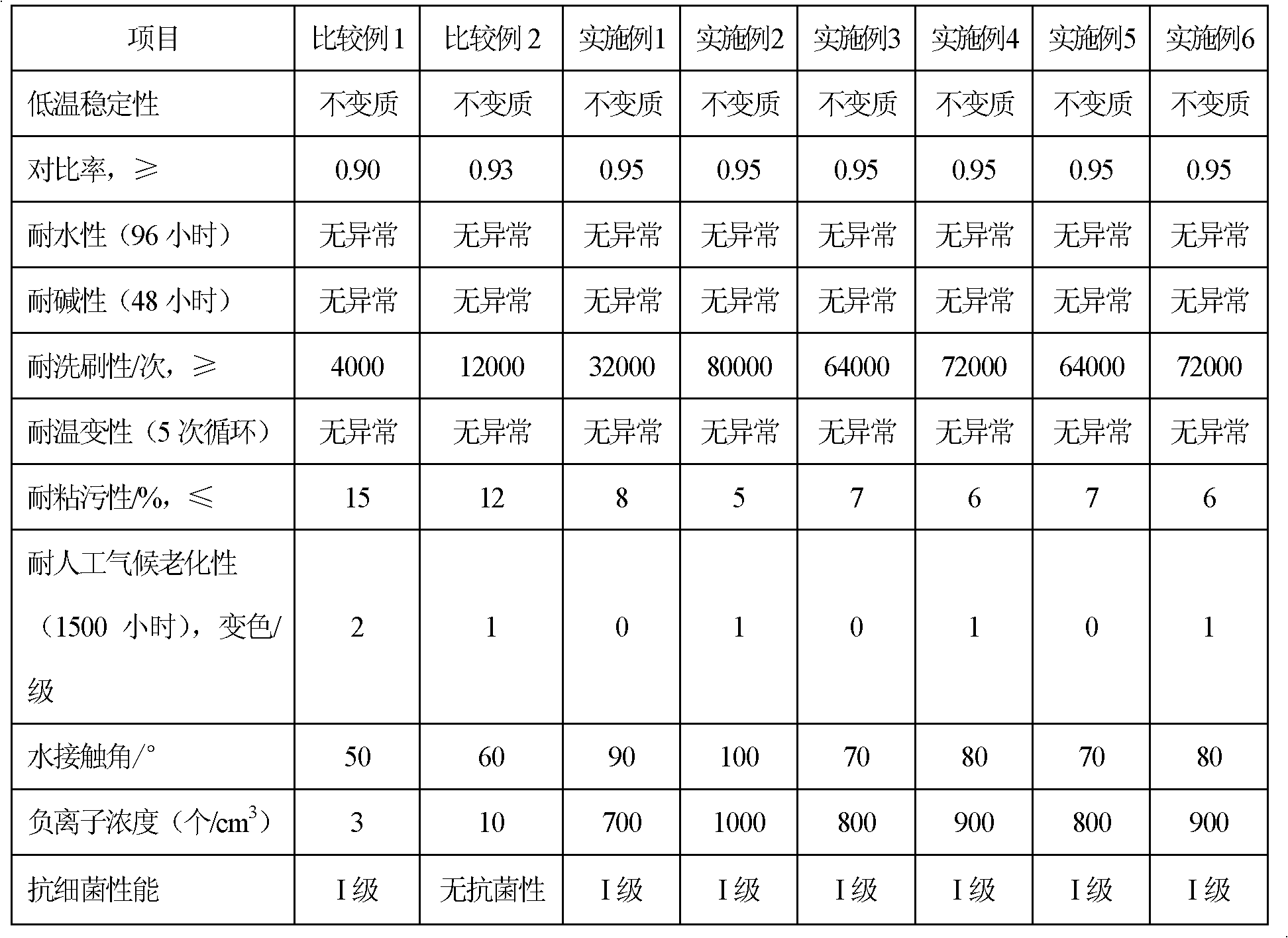

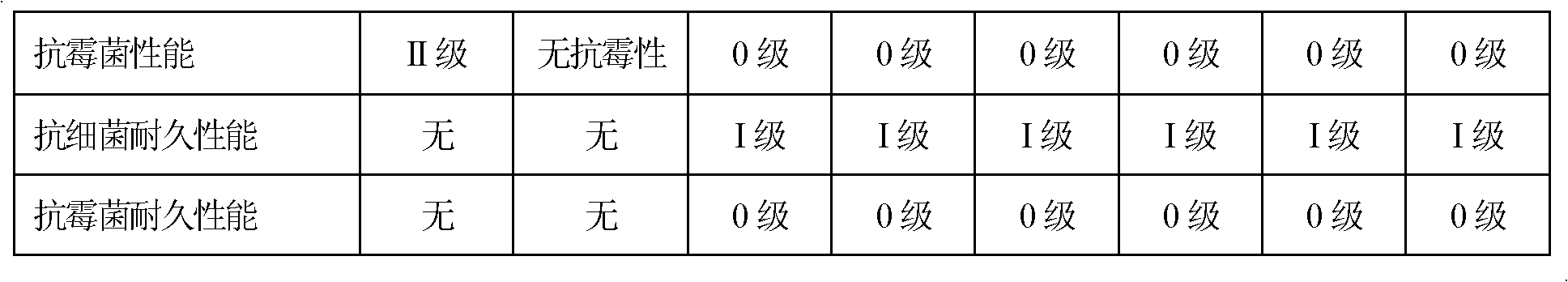

Examples

Embodiment 1

[0060] Weigh 840g of deionized water in a 2000ml beaker, stir at a high speed under the condition of 1000rpm with a high-speed disperser, add a polymer dispersant (in this embodiment, the polymer dispersant adopts Disperbyk192 of German Byk Chemical Company) 60g, add respectively 70g of magnesium oxide powder, 20g of zinc oxide powder and 10g of titanium oxide powder with an average particle size of 50nm were dispersed for 60 minutes, and the mixture was subjected to planetary ball milling for 5 hours at a speed of 300rpm to form a highly dispersed inorganic composite nano concentrated slurry. According to the original ratio, wherein the weight ratio of nano-magnesium oxide is 7%, the weight ratio of nano-zinc oxide is 2%, the weight ratio of nano-titanium oxide is 1%, the total weight ratio of composite powder is 10%, and the weight ratio of polymer dispersant is 6%.

[0061] The inorganic composite nano-concentrated slurry is added into nutrient broth medium (NB) with a powd...

Embodiment 2

[0064] Weigh 700g of deionized water in a 2000ml beaker, stir at a high speed under the condition of 2000rpm with a high-speed disperser, add a polymer dispersant (in this embodiment, the polymer dispersant adopts Disperbyk192 of German Byk Chemical Company) 100g, add respectively 40g of magnesium oxide powder, 120g of zinc oxide powder and 40g of titanium oxide powder with an average particle size of 60nm were dispersed for 120min, and the mixture was subjected to planetary ball milling for 10h at a ball mill speed of 500rpm to form a highly dispersed inorganic composite nano concentrated slurry. According to the original proportion, wherein the weight ratio of nano-magnesium oxide is 4%, the weight ratio of nano-zinc oxide is 12%, the weight ratio of nano-titanium oxide is 4%, the total weight ratio of composite powder is 20%, and the weight ratio of polymer dispersant is 10%.

[0065] The inorganic composite nano-concentrated slurry is added into nutrient broth medium (NB) ...

Embodiment 3

[0068] The difference from Example 1 is:

[0069] Take by weighing 800g of deionized water in a 2000ml beaker, stir at a high speed under the condition of 2500rpm with a high-speed disperser, add a polymer dispersant (in this embodiment, the polymer dispersant adopts Disperbyk192 of German Byk Chemical Company) 80g, add respectively 84g of magnesium oxide powder, 24g of zinc oxide powder, 10.8g of titanium oxide powder and 1.2g of copper oxide powder with an average particle size of 40nm, dispersed for 100min, the mixture was subjected to planetary ball milling for 8h, and the speed of the ball mill was 600rpm to form a highly dispersed inorganic composite nano concentration pulp. According to the original ratio, wherein the weight ratio of nano-magnesium oxide is 8.4%, the weight ratio of nano-zinc oxide is 2.4%, the weight ratio of nano-titanium oxide is 1.08%, the weight ratio of nano-copper oxide is 0.12%, and the total weight ratio of composite powder is 12%, the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com