Silicasol-acrylate emulsion compound primer

An acrylic ester and silica sol technology, which is applied in biocide-containing paints, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problem of high cost pressure of latex paint, difficulty in penetrating into porous substrates, and coating adhesion Variation and other problems, to achieve the effect of slowing down the phenomenon of salting out and efflorescence, cheap price, and good wrapping power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

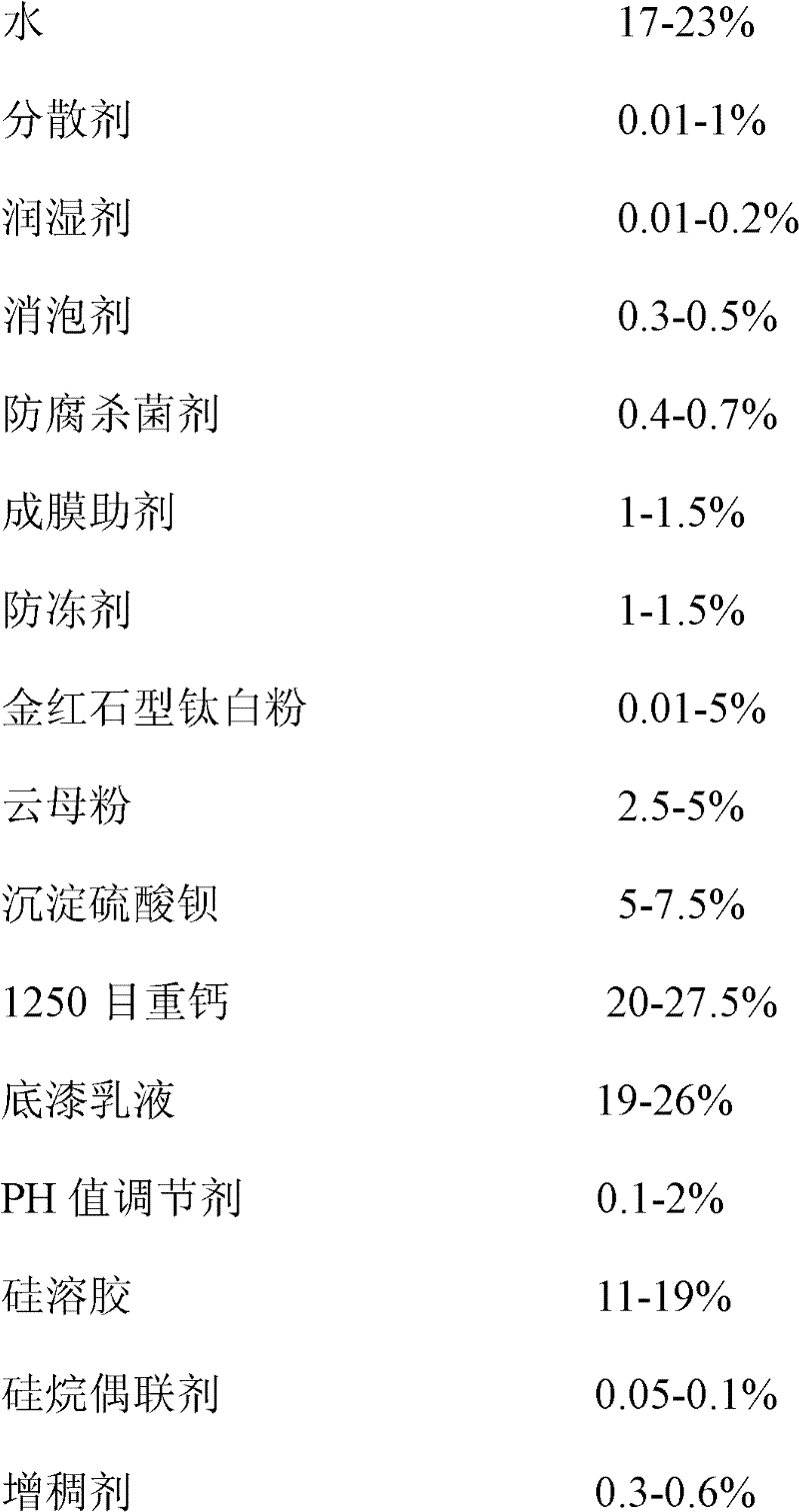

Method used

Image

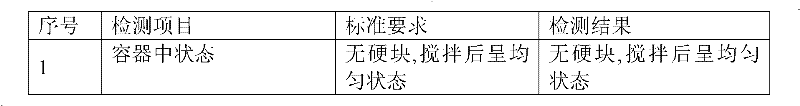

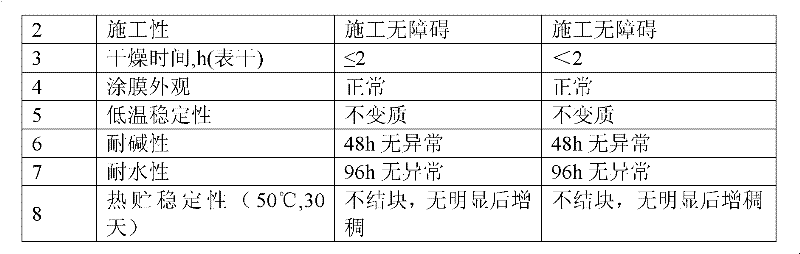

Examples

Embodiment 1

[0016] Take 200kg of water, weigh 2.5kg of thickener and add it at 300-500 rpm, preferably ACRYSOL 2020NPR from Rohm and Haas Company in the United States, stir evenly for 5 minutes, then slowly add 1kg of pH regulator, preferably with a concentration of 10% hydrogen Potassium oxide; gradually increase the speed to 500-700 rpm, and disperse for 3-5 minutes. During the dispersion process, put 6kg of dispersant, preferably Deqian (Shanghai) Chemical Co., Ltd. DisponerW-519; 1kg of wetting agent, preferably HyonicPE-100 of German Corning Company; 1kg defoamer, preferably FoamStarA10 of German Corning Company; 2.5kg antiseptic and bactericide, preferably Kathon LXE of Rohm and Haas Company of the United States; 13kg antifreeze agent, preferably calcium chloride; 12.5kg Coating aid, preferably ethylene glycol ether; gradually increase the speed to 1000-1300 rpm for dispersion, and put in 35kg of rutile titanium dioxide, preferably R-706 from DuPont Chemical; 42kg of mica powder; 68k...

Embodiment 2

[0018] Get 170kg of water, under 300-500 rev / min, take by weighing 3kg and be selected from the 250HBR cellulose of American Aqualon (add, after uniform stirring 5 minutes, slowly add 0.5kg concentration 10% potassium hydroxide; Raise rotating speed gradually to 500 -700 rpm, disperse for 3-5 minutes. During the dispersion process, 10kg of GA-40 selected from Ciba Fine Chemicals China Co., Ltd., 2kg selected from Shenzhen Haichuan Chemical Technology Co., Ltd. HYDROPALAT 188A, 2kg selected from Dispelair CF550, 5kg of Dispelair CF550 from British Blair Keben Chemical Co., Ltd., HF, 15kg of sodium nitrite, and 15kg of ethylene glycol; gradually increase the speed to 1000-1300 rpm for dispersion, and put in 50kg from Australia CR-828 from Kemeiqi Company, 50kg of mica powder, 75kg of precipitated barium sulfate, 275kg of 1250 mesh heavy calcium, and then increase the speed to 1800-2000 rpm, and the high-speed dispersion fineness is less than 45 microns; then turn the speed to 10...

Embodiment 3

[0020]Take 230 kg of water, and at 300-500 rpm, weigh 2 kg of ACRYSLO RM-8W selected from Rohm and Haas Company of the United States and add, and after uniform stirring for 5 minutes, slowly add 8 kg of AMP-95 selected from Dow Chemical; gradually Increase the rotation speed to 500-700 rpm, and disperse for 3-5 minutes. During the dispersion process, add 0.1kg of Dispersant 5027 from Japan Nopco Auxiliary Co., Ltd., and 0.1kg of HYDROPALAT from Shenzhen Haichuan Chemical Technology Co., Ltd. 306. 1kg is selected from Dispelair CF247 of Blair Keben Chemicals in the UK, 2kg is selected from Clariant Chemicals NipacideCI-15HS, 10kg of carbonate, 10kg of propylene glycol; gradually increase the speed to 1000-1300 rpm for dispersion, and put in 0.1 kg is selected from CR-826, 25kg of mica powder, 50kg of precipitated barium sulfate, and 200kg of 1250 mesh heavy calcium from Kemeiqi Company in Australia. Then, the speed is increased to 1800-2000 rpm, and the high-speed dispersion fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com