Treatment method for recovering and utilizing trimanganese tetroxide industrial wastewater

A technology of trimanganese tetroxide and industrial wastewater, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of deep deamination of ammonia and manganese ion Unstable removal effect, waste of water resources and other problems, to achieve the effect of easy control of process conditions, good removal effect, and satisfying the effect of returning to production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

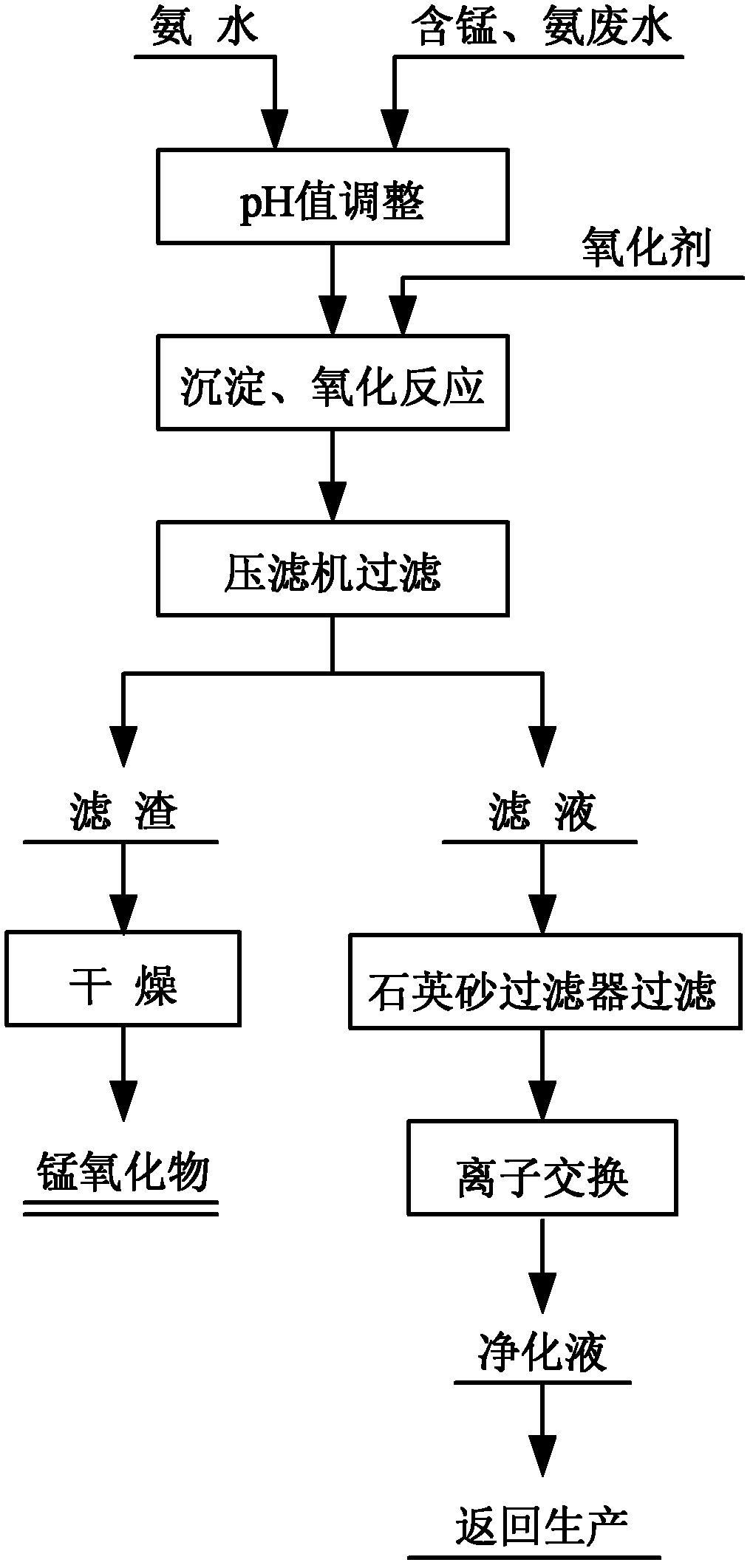

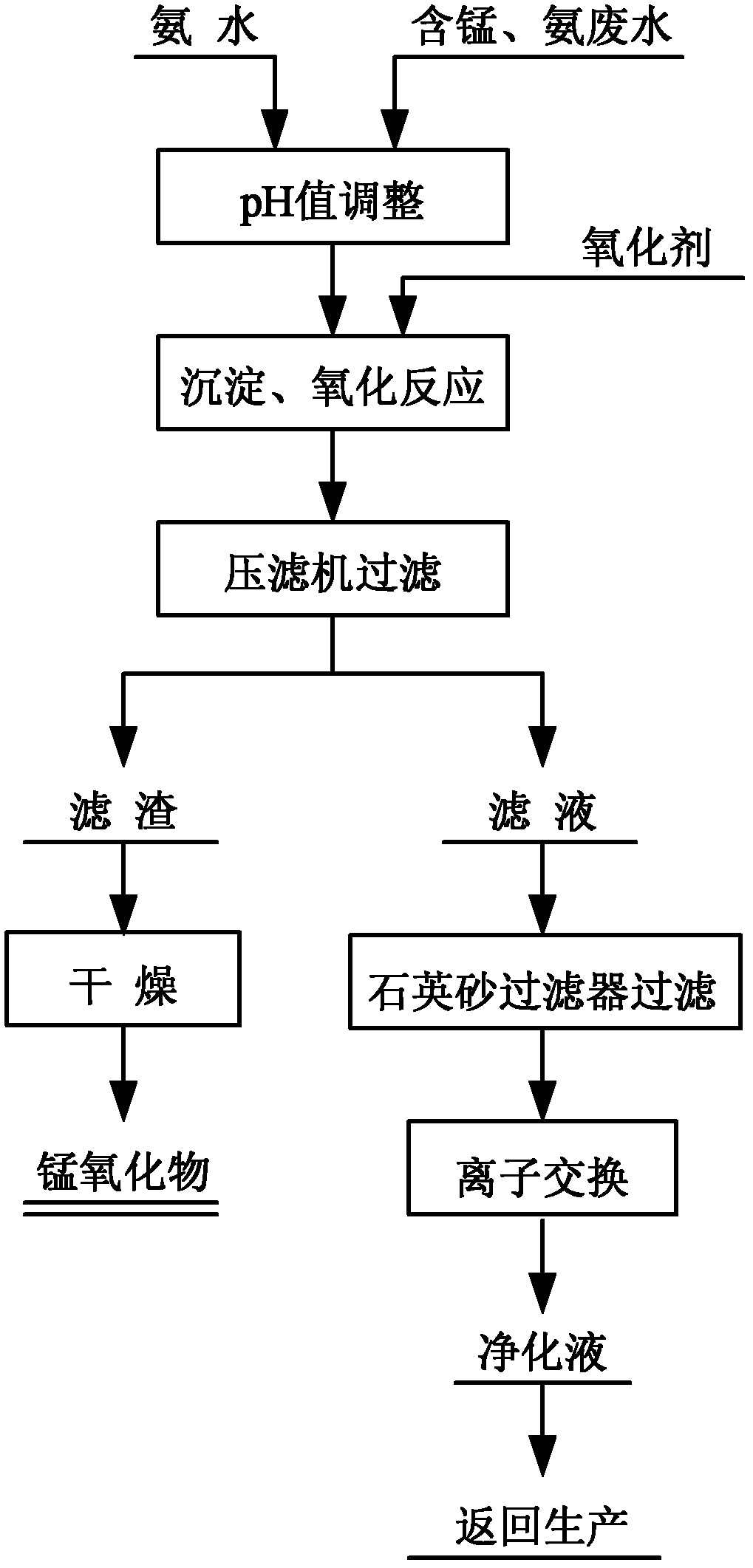

[0021] Embodiment 1: see figure 1 , main ion concentration in wastewater: Mn 2+ >50mg / L; Ca 2+ >5mg / L; Mg 2+ >5mg / L:

[0022] (a), adding ammonia water (mass concentration: 25%) with a volume of 0-5% of the volume of the wastewater into the wastewater, and adjusting the pH between 9 and 10 to generate Mn(OH) 2 precipitation;

[0023] (b), adding volume to waste water is the hydrogen peroxide (mass concentration: 28%) of 0~2% of waste water volume as oxidizing agent, and the reaction time is 1~180min; Let the low price manganese hydroxide that generates be oxidized rapidly into high valence state Manganese oxides, making Mn 2+ The concentration is lower than 0.5mg / L;

[0024] (c), will filter with filter press and reclaim the waste water behind the manganese oxide and further remove fine particle by quartz sand filter;

[0025] (d), the liquid that (c) obtains is set as 100ml / h import ion exchange column that cation exchange resin is housed with flow rate, removes the ca...

Embodiment 2

[0027] Add 10ml ammonia water (mass concentration: 25%) to 4L waste water as neutralizer, adjust pH to be 9~10, then add 4ml hydrogen peroxide (mass concentration: 28%), at room temperature, 200r / min mechanical stirring, reaction 60min. After liquid-solid separation, the manganese ion content after pretreatment is as low as 0.02mg / L. The liquid was then introduced into a container containing 30ml H + Type D113 type cation exchange resin ion exchange column, the flow rate is set to 100ml / h, the Mn in the effluent 2+ 2+ 2+ <0.01mg / L.

Embodiment 3

[0029] Add 10ml of ammonia water (mass concentration: 25%) into 4L of waste water as a neutralizing agent, adjust the pH to 9-10, then pass in air with an air flow of 50L / h, mechanical stirring at 400r / min, and react at room temperature 3h. After liquid-solid separation, the manganese ion content after pretreatment is as low as 0.03mg / L. The liquid was then introduced into a container containing 30ml NH 4 + Type D001 type cation exchange resin ion exchange column, the flow rate is set to 100ml / h, the Mn in the effluent 2+ 2+ 2+ <0.01mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com