Microbial Activity Improvement Agent, Microbial Activity Improvement Method, And Biological Waste Treatment Method

A technology of microbial activity and improver, applied in microbial treatment, biological sludge treatment, biological water/sewage treatment, etc., can solve the problem of not intentionally increasing microbial activity, and achieve efficient and stable waste treatment, cost realization , the effect of improving processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (Example 1) (Preparation of Extract Liquid Containing Microbial Activity Improver)

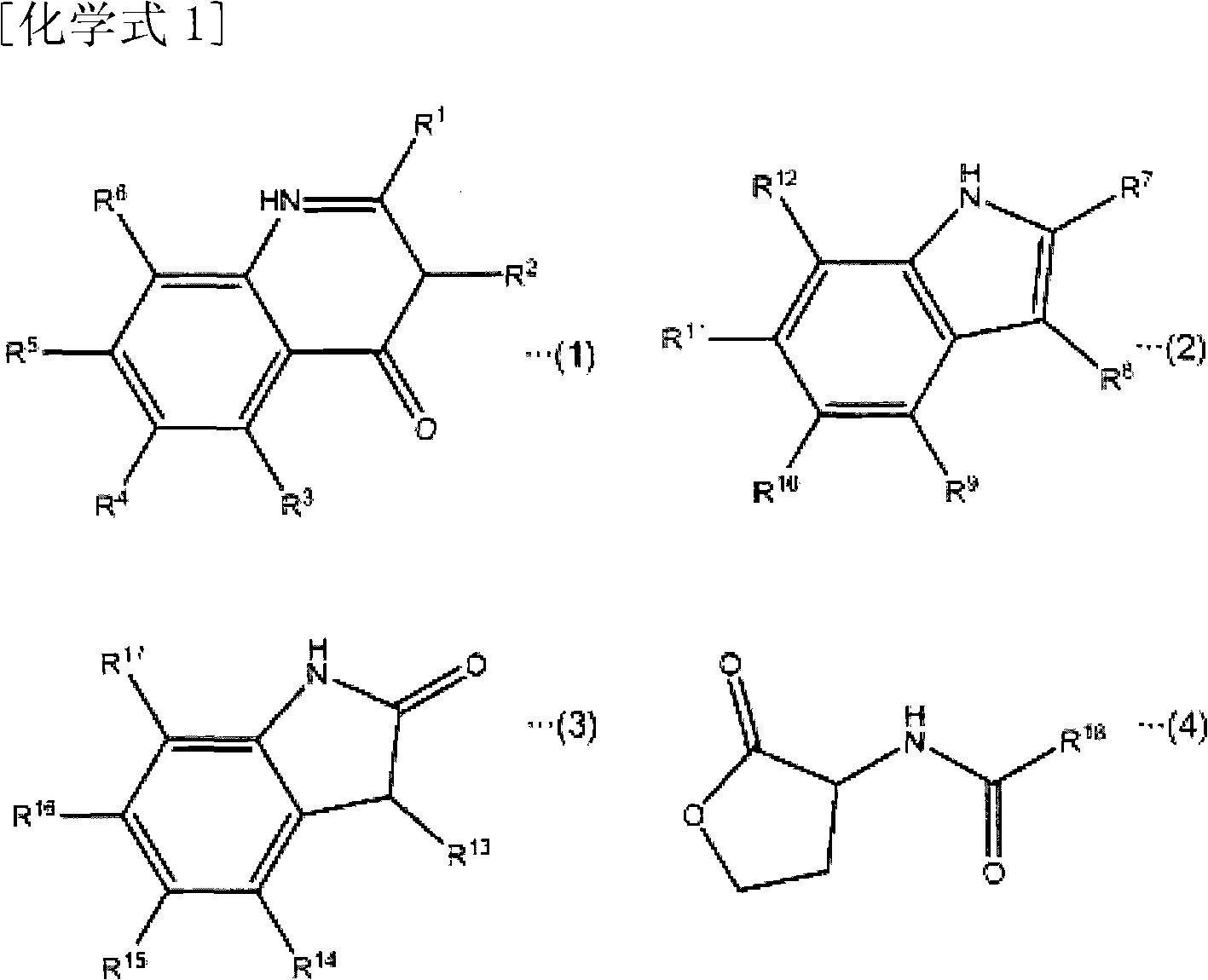

[0065] Sludge was collected from more than ten Expanded Granular Sludge Bed (EGSB) reactors, and cultured with waste (artificial wastewater) with the composition shown in Table 1. The compositions of solution A, solution B and solution C in Table 1 are shown in Tables 2-4, respectively. From these sludges, the sludge with the highest methane production activity is selected. Evaluation of methanogenesis activity was performed by the method described in Example 2. Compounds secreted from microorganisms contained in the sludge were analyzed by liquid chromatography-time-of-flight mass spectrometry (LC-TOF-MS). As a result, it was found that compounds represented by the following chemical formulas (8) to (21) exist in the sludge. The concentration of each compound was estimated from the peak area of LC-TOF-MS, and it was hundreds of nmol / L to several tens of μmol / L.

[0066] [Table 1]...

Embodiment 2

[0081] (Example 2) (Evaluation of methanogenesis activity of sludge)

[0082]Methanogenic activity of sludge was evaluated by quantifying the mcrA gene encoding methyl-coenzyme M reductase, which is an enzyme unique to methanogens, by RT-PCR. Methanogens are microorganisms that synthesize methane under anoxic conditions. A difference of about 10-fold was observed in the amount of mcrA gene present in each sludge sample. The sludge with the highest amount of mcrA gene was selected as the sludge with high methanogenesis activity.

Embodiment 3

[0083] (Example 3) (Evaluation of Microbial Activity Improver)

[0084] Sludge is taken from the domestic EGSB reactor, and the crushed sludge is removed with a sieve to prepare granular sludge. Granular sludge refers to sludge in which microorganisms are granular. The diameter of the granular sludge used in this Example was about 1-3 mm. Artificial waste (artificial wastewater) with a COD of 15000 mg / L using glucose as a carbon source was added to this granular sludge, and cultured for 2 months under the condition of a sludge load of 0.3 [COD(g) / MLSS(g)].

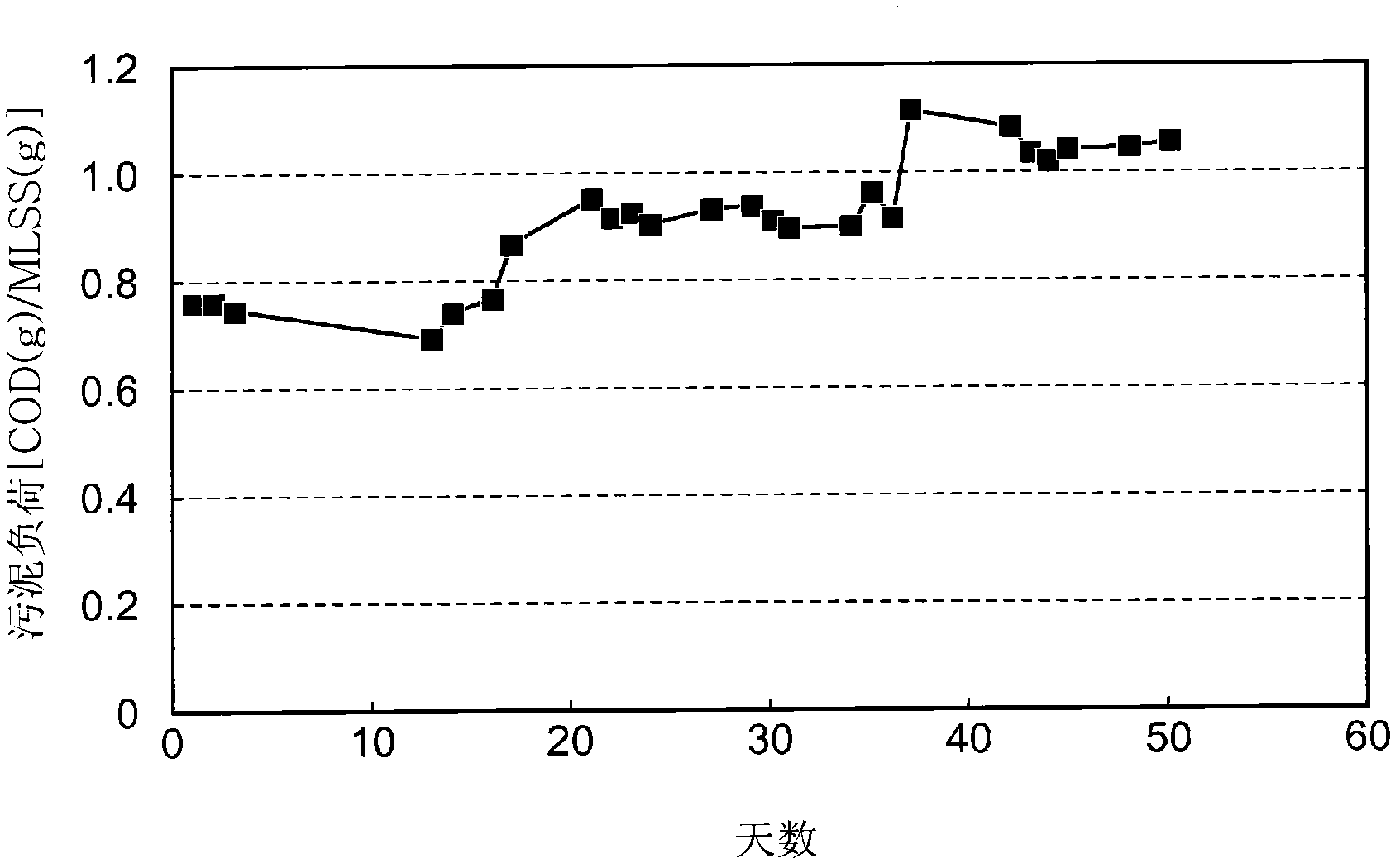

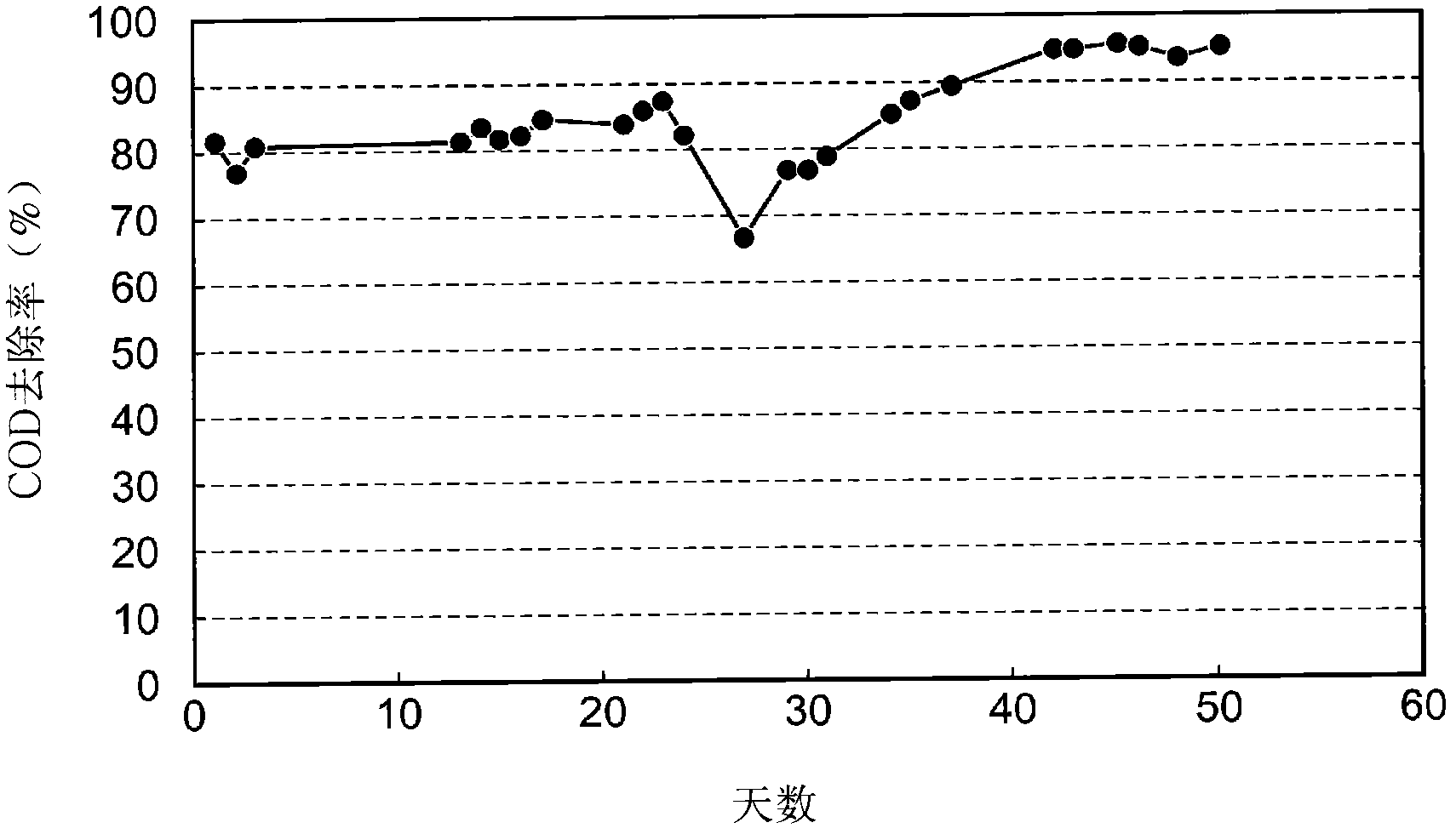

[0085] Using the cultivated granular sludge, biological waste was treated with an Upflow Anaerobic Sludge Blanket (UASB) device. The UASB device used was cylindrical with a volume of 1.5 L, an inner diameter of 60 mm, and a height of 1 m. 500 ml of the above-mentioned granular sludge was stored in a UASB device, and supplied to waste (artificial wastewater) having a composition shown in Table 5, and subjected to biologi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com