Method for preparing hydrogen and nitrogen gas with specific composition from multi-ingredient gas containing H2 and N2

A multi-component, nitrogen technology, applied in hydrogen production, gas fuel, petroleum industry, etc., can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

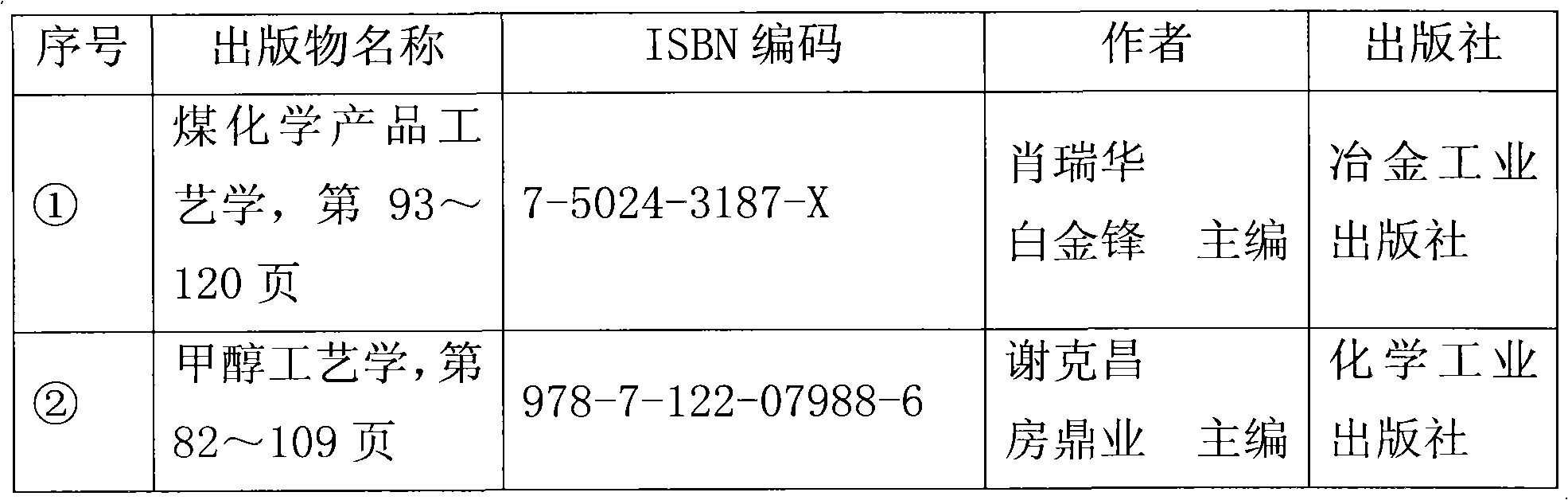

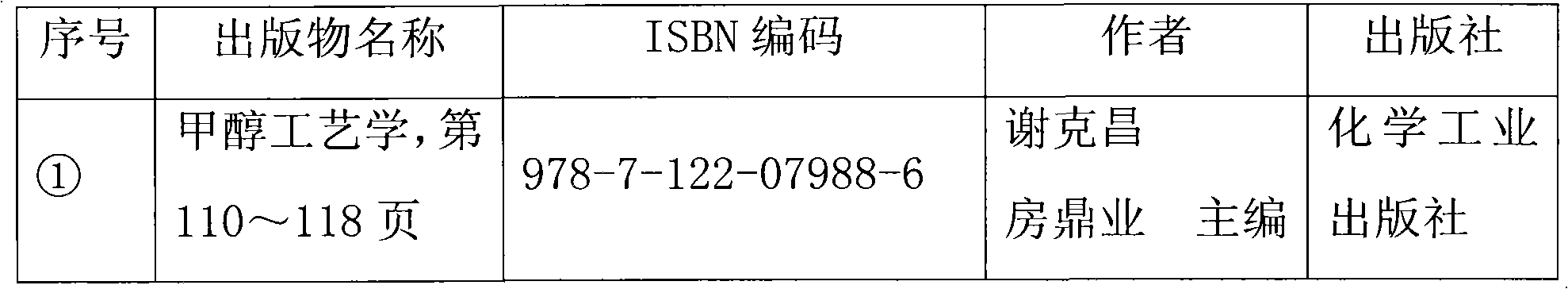

Examples

Embodiment 1

[0249] This embodiment is a co-production process of co-production of raw material gas for synthesis of ammonia, including the following steps:

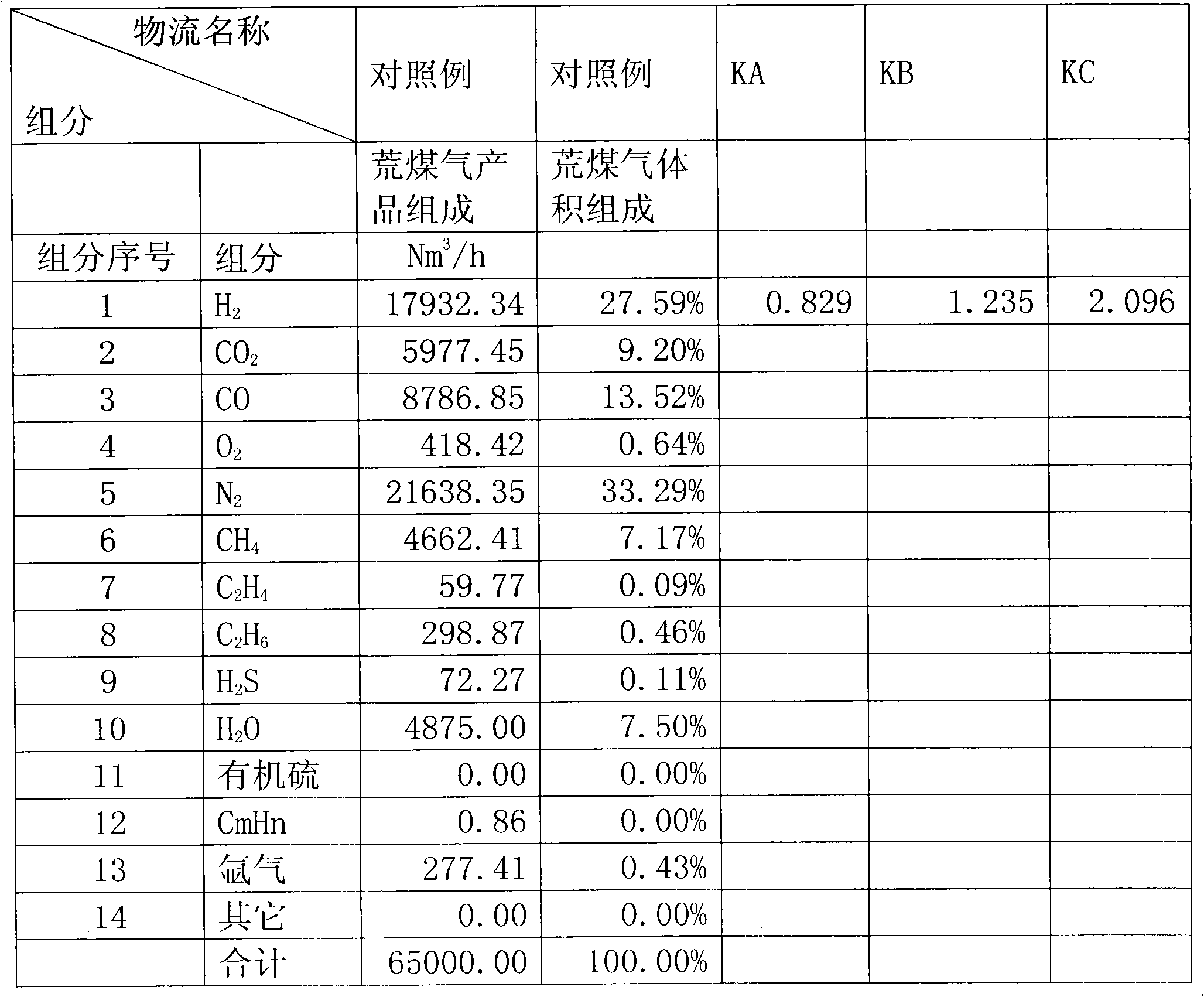

[0250] ①The combustion chamber of the carbonization furnace in the process of carbonization of internal heating coal carbonization to semi-coke uses air as the oxidant, and the composition of the off-ring gas is shown in Table 9-1, which belongs to CO 2 -CO-CH 4 - Rich N 2 -H 2 Department of matter;

[0251] ②In the off-ring gas comprehensive processing unit 300, complete the following tasks:

[0252] a from the ring gas to complete the "wet hydrogen sulfide removal process" 1101, the H 2 The volume concentration of S is reduced to ~0.02%. The gas is divided into two parts in the process flow. The first part of the gas becomes desulfurized gas through the solvent absorption process using 1 or 2 solvent absorption towers. The rich solvent is mixed with air and regenerated simultaneously. Foam sulfur, the foam sulfur passes throug...

Embodiment 2

[0313] Based on Embodiment 1, a comprehensive treatment gas pre-separation step 1500 is set in step 1000, and the separation of comprehensive treatment gas TF100 can be obtained mainly by H 2 and N 2 Composition of feed gas F100, deCO 2 off N 2 Rich in methane, rich in CO 2 gas, the deCO generated in step 1500 2 off N 2 The methane-enriched gas is used as a natural gas substitute, and the present invention is combined with the production process of the natural gas substitute to form a co-production natural gas process.

Embodiment 3

[0315] Based on Example 1, the deCO generated in step 1500 2 off N 2 The methane-enriched gas is used as raw material gas for producing liquefied methane gas, and the present invention is combined with a liquefied natural gas production process to form a co-production LNG process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com