Surface modified nanometer diamond particle as well as preparation method and application thereof

A nano-diamond, surface modification technology, applied in the field of nano-diamond, to achieve the effect of sufficient modification, uniform distribution of OH bonds, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

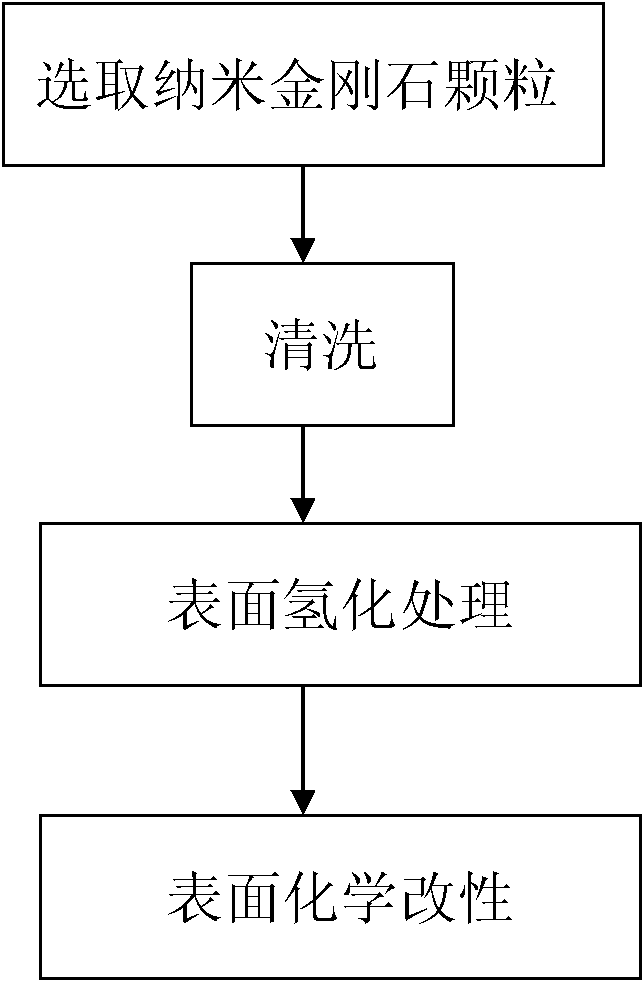

[0038] Such as figure 1 Shown, the preparation method of the surface-modified nano-diamond particle of the present embodiment, comprises the following steps:

[0039] (1) cleaning the nano-diamond particles, specifically comprising the following steps:

[0040] (1-1) get average particle size and be 1 gram of nano-diamond particle of 150nm, remove metal impurity and remove graphite impurity;

[0041] Wherein removing metal impurities specifically comprises the following steps:

[0042] Nano-diamond particles are placed in a mixed solution of hydrochloric acid and nitric acid, and heated at 100°C for 1 hour to remove metal impurities in the nano-diamond; wherein the mixed solution of hydrochloric acid and nitric acid is composed of 37% hydrochloric acid and 68% nitric acid. 3:1 volume ratio composition.

[0043] Wherein removing graphite impurity specifically comprises the following steps:

[0044] Place the nano-diamond particles in a mixture of sulfuric acid and nitric ac...

Embodiment 2

[0055] The preparation method of the surface-modified nano-diamond particle of the present embodiment, comprises the following steps:

[0056] (1) cleaning the nano-diamond particles, specifically comprising the following steps:

[0057] (1-1) Get 1 gram of nano-diamond particles with an average particle diameter of about 50nm, remove metal impurities and remove graphite impurities;

[0058] Wherein removing metal impurities specifically comprises the following steps:

[0059] Nano-diamond particles are placed in a mixed solution of hydrochloric acid and nitric acid, and heated at 150°C for 3 hours to remove metal impurities in the nano-diamond; wherein the mixed solution of hydrochloric acid and nitric acid is composed of 37% hydrochloric acid and 68% nitric acid. 1:1 volume ratio composition.

[0060] Wherein removing graphite impurity specifically comprises the following steps:

[0061] Place the nano-diamond particles in a mixture of sulfuric acid and nitric acid, and h...

Embodiment 3

[0068] The preparation method of the surface-modified nano-diamond particle of the present embodiment, comprises the following steps:

[0069] (1) cleaning the nano-diamond particles, specifically comprising the following steps:

[0070] (1-1) get average particle diameter and be 1 gram of nano-diamond particle of 5nm, remove metal impurity and remove graphite impurity;

[0071] Wherein removing metal impurities specifically comprises the following steps:

[0072] Nano-diamond particles are placed in a mixed solution of hydrochloric acid and nitric acid, and heated at 120°C for 2 hours to remove metal impurities in the nano-diamond; wherein the mixed solution of hydrochloric acid and nitric acid is composed of 37% hydrochloric acid and 68% nitric acid. 2:1 volume ratio composition.

[0073] Wherein removing graphite impurity specifically comprises the following steps:

[0074] Place the nano-diamond particles in a mixture of sulfuric acid and nitric acid, and heat them at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com