Method for producing cupric chloride basic by using scrap copper

A copper chloride, basic technology, applied in the field of preparation of feed additive basic copper chloride, can solve the chemical properties of low content of dioxins and polychlorinated biphenyls, residual dioxins and polychlorinated biphenyls, redox power Weak problems such as meeting environmental protection and cleaner production, reducing feed consumption, and high absorption and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

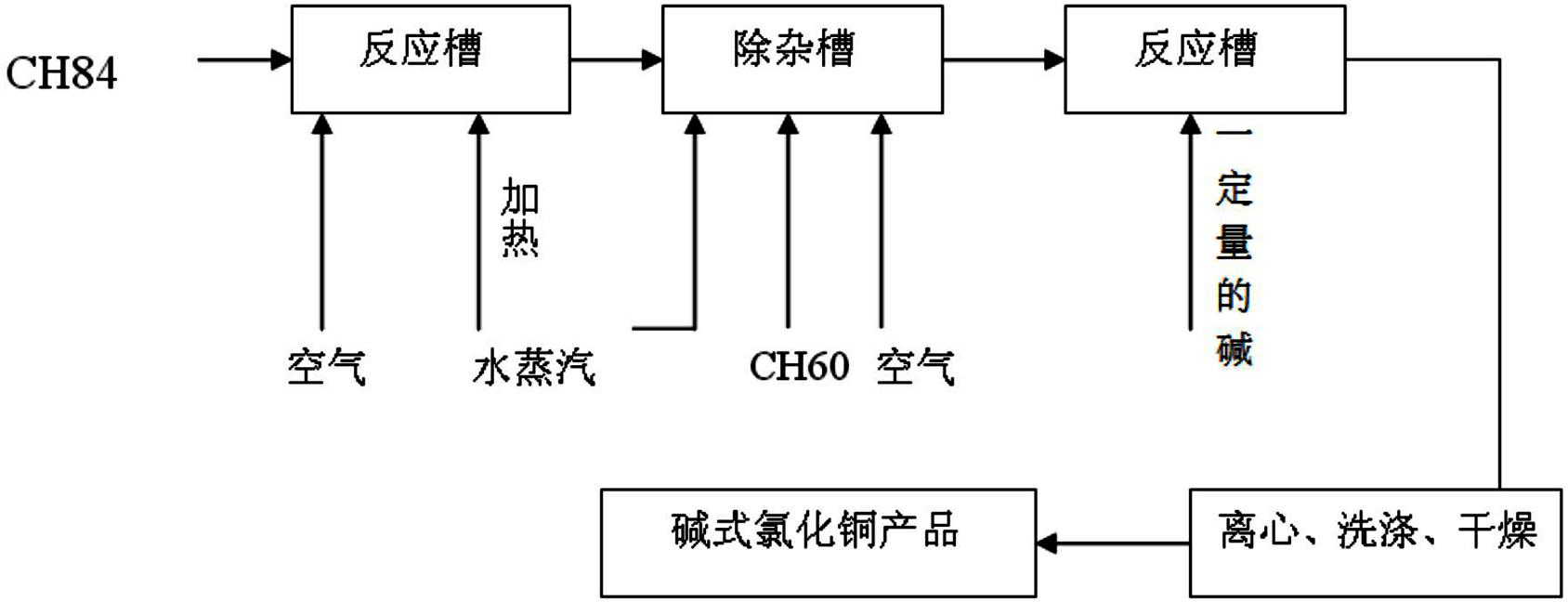

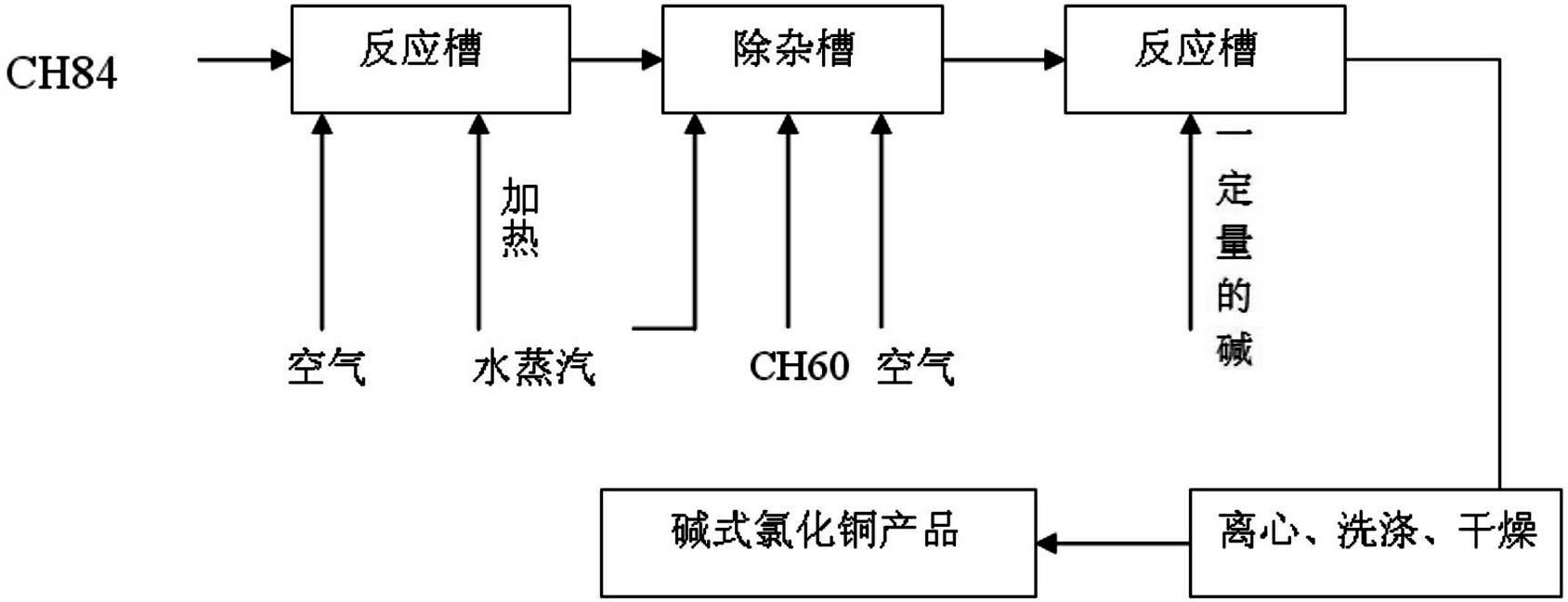

[0025] a kind of like figure 1 The preparation method of shown basic cupric chloride of the present invention may further comprise the steps:

[0026] (1) Preparation of copper chloride: first add 500ml of dilute hydrochloric acid with a mass fraction of 20% to the reaction pot as a reaction solution, which also contains Cu with a concentration of 7.8g / L 2+ , then turn on the stirring device, and add 100g of scrap copper raw material into the reaction pot (the scrap copper of this embodiment includes copper filings produced by copper processing, discarded copper wires and enameled wires, etc.) and 4g of catalyst CH84 (CH84 catalyst can Manganese, vanadium, copper, iron, titanium compounds or any combination of the above-mentioned compounds); start to pass steam into the reaction pot and heat it to about 70°C, and continuously blow in air (the air should be evenly arranged And control the air volume), under this condition, the copper-dissolving reaction is carried out. After t...

Embodiment 2

[0029] a kind of like figure 1 The preparation method of shown basic cupric chloride of the present invention may further comprise the steps:

[0030] (1) Preparation of copper chloride: first add 1100ml of dilute hydrochloric acid with a mass fraction of 15% to the reaction pot as a reaction solution, which also contains Cu with a concentration of 9.5g / L 2+ , then turn on the stirring device, and add 200g of waste copper raw materials into the reaction pot (the waste copper of this embodiment includes copper filings produced by copper processing, discarded copper wires and enameled wires, etc.) and 10g of catalyst CH84 (CH84 catalyst can Manganese, vanadium, copper, iron, titanium compounds or any combination of the above-mentioned compounds); start to pass steam into the reaction pot and heat it to about 80°C, and continuously blow in air (the air should be evenly arranged And control the air volume), under this condition, the copper-dissolving reaction is carried out. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com