Copolyether ester, elastic buffer member prepared thereby, preparation method of elastic buffer member, and rail traffic vehicle provided with elastic buffer member

A technology of copolyetherester and elastic buffering, which is applied to springs, buffers, and mechanical equipment made of plastic materials, can solve the problems of high cost, heavy weight and complex structure of buffers, and achieve high production efficiency and simple structure. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

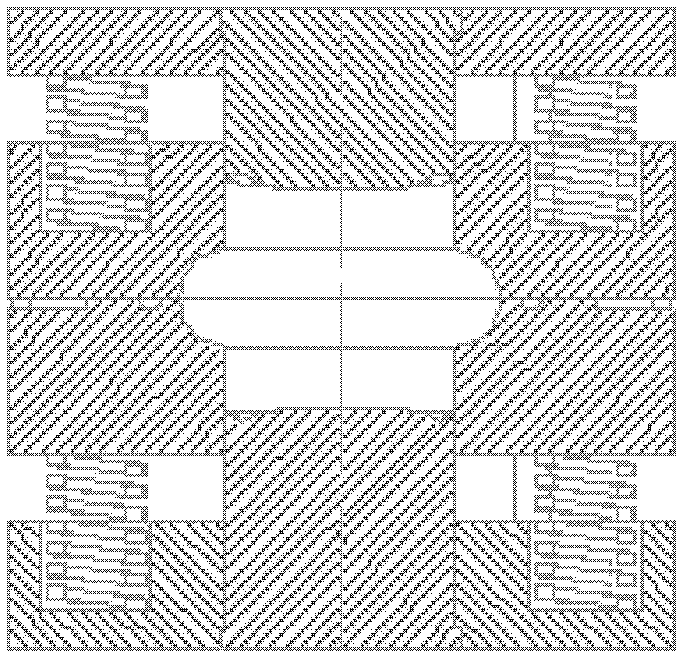

[0026] The present invention also provides a method for preparing an elastic buffer, the method comprising the following steps: preparing the above-mentioned copolyether ester; then uniformly mixing the copolyether ester, a crosslinking agent, and a nucleating agent, and obtaining a film embryo by injection molding; The membrane embryo is further placed in a compression mold for compression molding. In the above preparation process, the copolyetherester and the crosslinking agent realize micro-crosslinking in the injection molding process. Through micro-crosslinking, the material itself forms a partial network structure, similar to the crosslinking of rubber, so that the formed elastic buffer has creep resistance, bending fatigue and outstanding chemical resistance.

[0027]Cross-linking agent refers to a substance that can act as a bridge between linear molecules so that multiple linear molecules can be cross-linked into a network structure. Usually, such molecules contain fu...

Embodiment 1

[0042] Example 1 (ratio of each component=100:80:24:6, polytetrahydrofuran ether: hydroxyl-terminated polybutadiene=4:1)

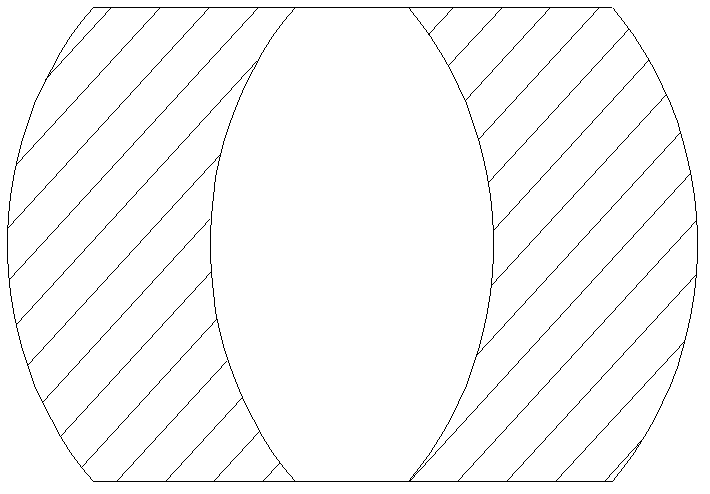

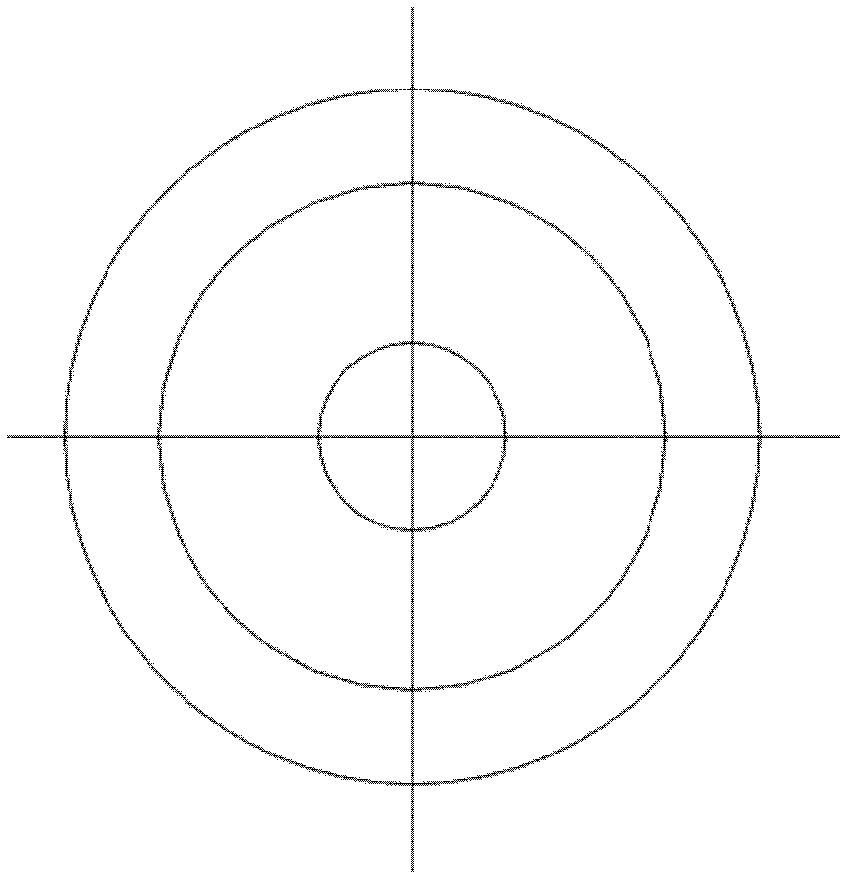

[0043] Dimethyl terephthalate (1941g), 1,4-butanediol (1552g), polytetrahydrofuran ether (465g), hydroxyl-terminated polybutadiene (116g), tetrabutyl titanate (20g), antioxidant Agent 1010 (8.2g) was added into the polymerization kettle, and the copolyether ester was obtained through transesterification and polycondensation. The reaction steps were the same as those of the comparative example, and will not be repeated here. After testing, the hardness of the copolyether ester is Shore D68, and the number average molecular weight Mn is 30000 (GPC test, solvent chloroform), copolyether ester and 0.02% dicumyl peroxide and 1% nano-montmorillonite Mix well, according to figure 1 The shape of the mold is injection molded, and the mold base is placed in the compression tooling (such as figure 2 shown), at a temperature of 80° C. and a pressure of 1000 kN, com...

Embodiment 2

[0044] Example 2 (ratio of each component=100:83:28:6.6, polytetrahydrofuran ether: hydroxyl-terminated polybutadiene=4.2:1)

[0045] Dimethyl terephthalate (1941g), 1,4-butanediol (1611g), polytetrahydrofuran ether (547g), hydroxyl-terminated polybutadiene (129g), tetrabutyl titanate (21.1g), anti Oxygen agent 1010 (8.5g) was added to the polymerization kettle, and copolyether ester was obtained through transesterification and polycondensation reaction. The hardness of the copolyether ester was Shore D60, and the number average molecular weight Mn was 33000 (GPC test, solvent chloroform), copolymerized Mix the ether ester with 0.15% dicumyl peroxide and 0.8% nano-montmorillonite evenly, and inject the mold base to make the mold base. The mold base is placed in the compression tooling and compressed for three cycles at a temperature of 150°C and a pressure of 2000kN. The samples of the buffer pads were obtained, and their properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com